The reason for the lack of oil pressure was apparent when I pulled the intake off. The #6 intake lifter was laying in the lifter valley along with a bent pushrod. The Cleveland routes oil to the mains from one of the lifter galleries, like an Olds, Pontiac, etc. Of course, #6 was on the passenger side, which happened to be the gallery that fed the mains.

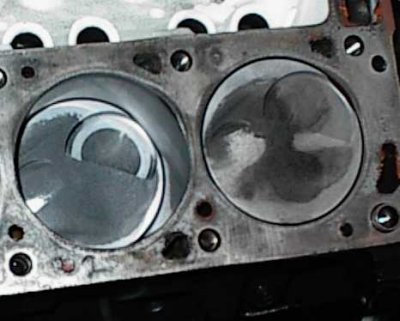

I now knew what caused the loss of oil pressure, but not why. My first thought was that I'd revved the engine too high, floated a valve, and so forth. (did I mention it sounded gooood?) There was a print of the intake valve in the carbon on top of the piston. But there was no sign of contact with any other valves; if I'd floated one bad enough to bend a pushrod, they should all have been touching. To top it off, the valve was stuck in the head.

I drove the stuck valve out, ran the spring across the checker, and scratched my head a while. Hmm. Well, time to suck it up and ask for another opinion. I tossed the parts in the car and made the rounds of a couple of local racing engine builders. After the obligatory ribbing sessions, they both were of the opinion that the valve stem clearance had been too tight.

Two of the valve guides had been broken off at the top when I received the heads. It's not an uncommon thing, but it makes it impossible to use the thinwall guide liners I'm set up for, so I had installed solid cast iron guides in... #6 intake and #7 exhaust. I took a look at #7. Hmm, the stem looked a little funny, but the clearance was fine. After much thought and discussion, I had another "learning experience." There are various figures for valve stem clearance, ranging from .0015" to .0045". I usually work down at .0015". It turns out that's just fine for bronze guides, but iron guides need more clearance. A brand new Chevy Vortec head, for example, is .004". The guide had been just a hair too tight. Damn. Those "learning experiences" can get expensive...

Note the heavier carbon buildup on the exhaust side; this is a perfect flame

pattern, with the flame front proceeding from the exhaust side to the cooler

intake side. Head designers and exotic head porters will reshape the chamber,

move the spark plug fiddle with the bowl area, and tinker with the piston

shape to try to get something like this. The Australian heads have it to

start with, which is one reason they make as much power as the 4V heads

despite flowing less air.

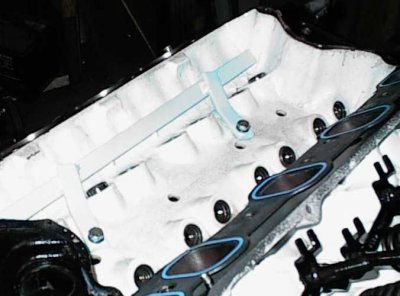

The fancy white paint in the lifter valley doesn't look so great any more, but

it's only paint...

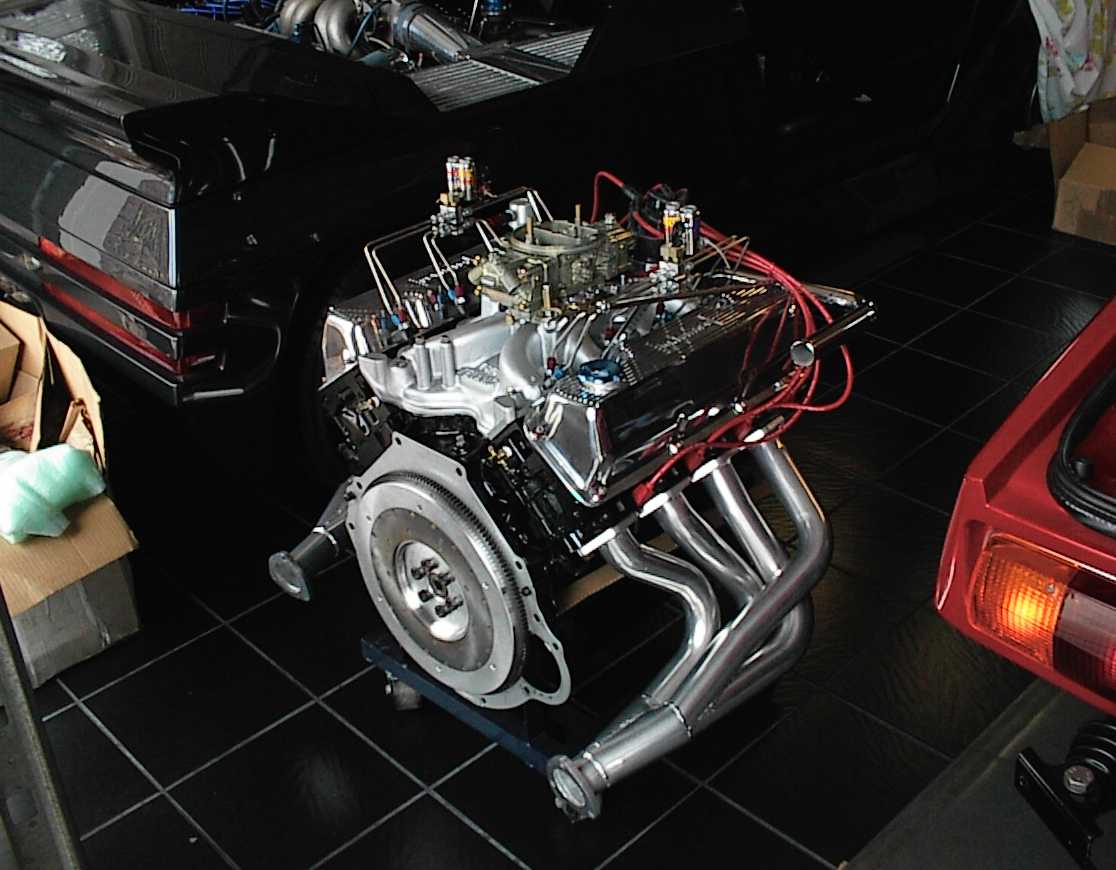

The engine bay is detailed better than the outsides of most show cars. The

new handbuilt aluminum fuel tank has to go in first, to the left, behind the

driver. Then the engine and transaxle go in.

The engine bay is detailed better than the outsides of most show cars. The

new handbuilt aluminum fuel tank has to go in first, to the left, behind the

driver. Then the engine and transaxle go in.

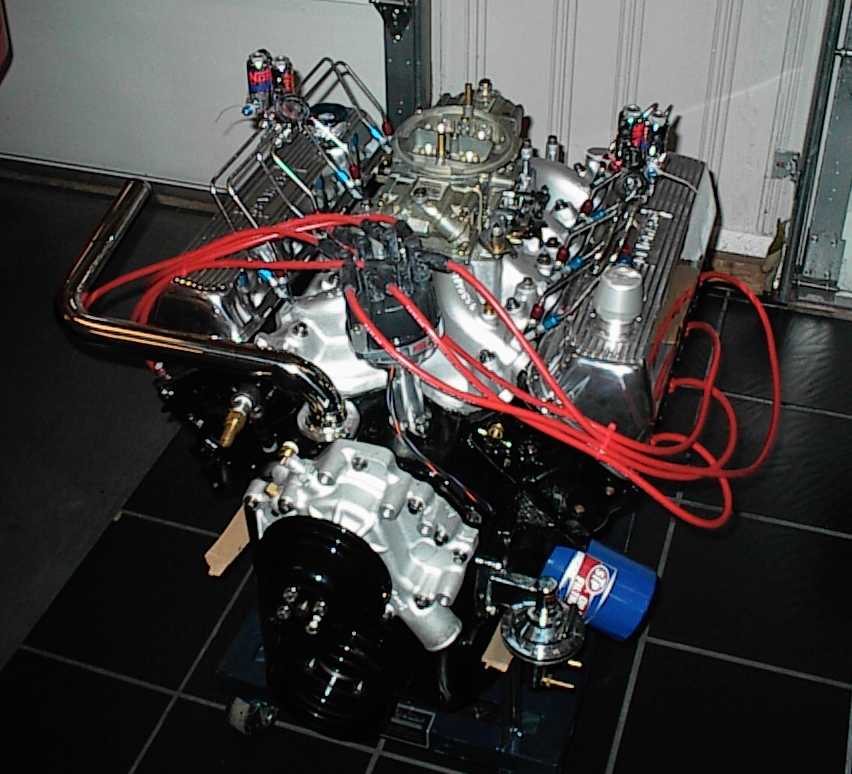

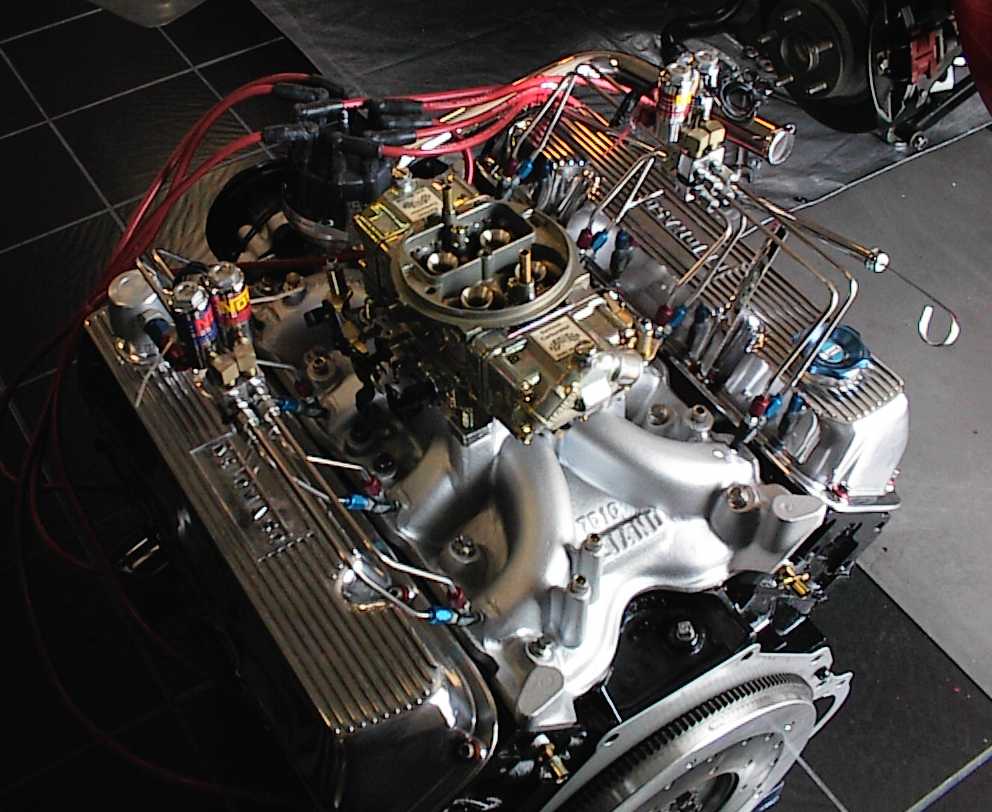

We took my black valve covers off and installed the new 'Pantera' cast

aluminum ones, then added the rest of the paraphernalia to take some trophy

shots before it goes into the car.

We took my black valve covers off and installed the new 'Pantera' cast

aluminum ones, then added the rest of the paraphernalia to take some trophy

shots before it goes into the car.

Alex will do something better with the spark plug wire routing later. The

powdercoated water tube has been replaced with a chrome one, in case you were

wondering.

Alex will do something better with the spark plug wire routing later. The

powdercoated water tube has been replaced with a chrome one, in case you were

wondering.

The nitrous lines actually clear the valve covers just fine. The guy who bent

them up did a nice job. Besides looking nice, they're well out of the way of

the carburetor so you can work on it without bumping into them.

The nitrous lines actually clear the valve covers just fine. The guy who bent

them up did a nice job. Besides looking nice, they're well out of the way of

the carburetor so you can work on it without bumping into them.

Pantera to the right, Vector to the left... new Jet-Hot coated headers.

Pantera to the right, Vector to the left... new Jet-Hot coated headers.