We built this fixture to lift the snout with - just grabbing the sides would

have bowed the strut towers in.

Jockeying the Supra snout up against the front of the Mustang shell.

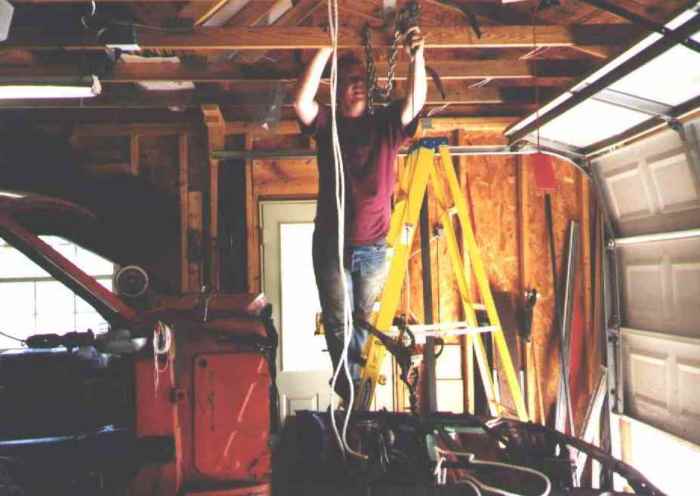

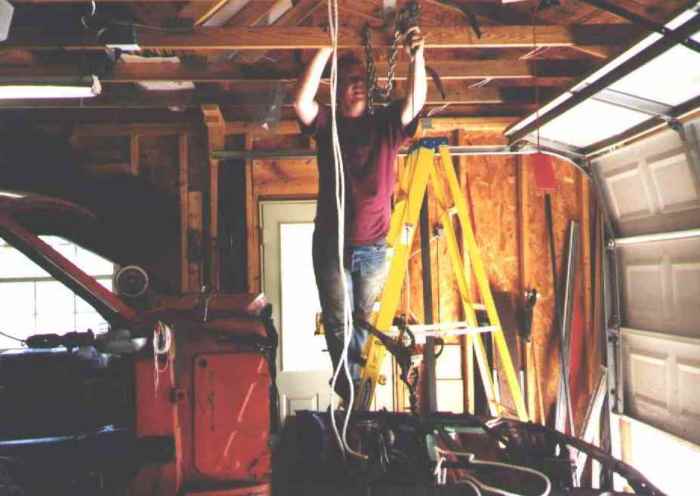

Sean lifts the clip into place.

Sean calculates the fangle factor...

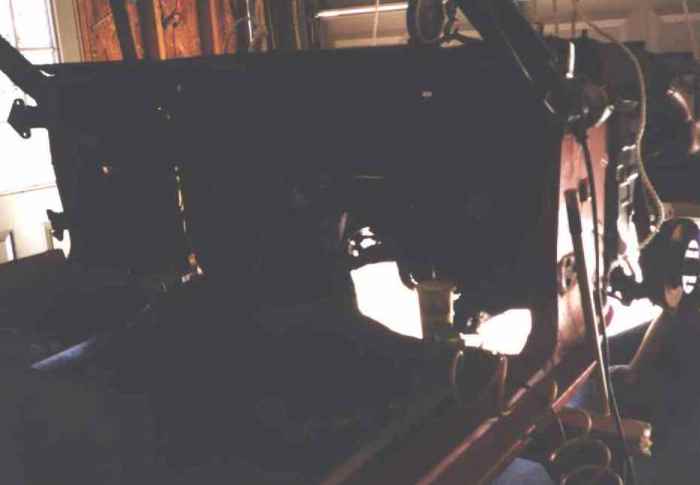

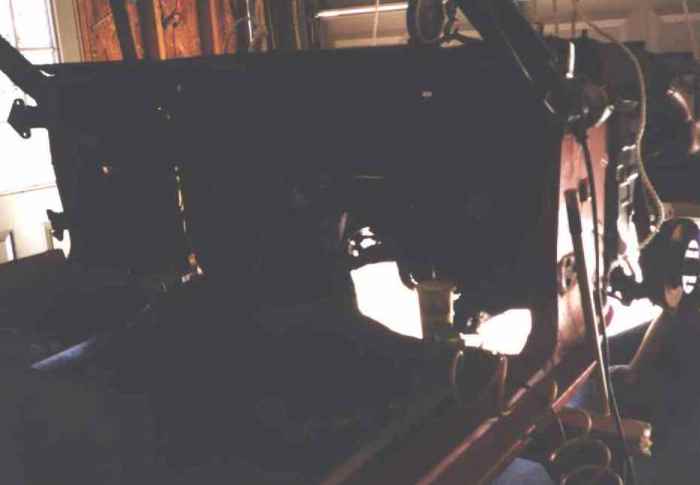

We're hanging a little low here - the snout will match right up against the

cut line on the Mustang firewall. The Supra torque box will fit inside what

used to be the Mustang's air plenum, which was all the torque box the Mustang

had.

The Supra snout is lifted in place. Well, approximately, anyway. The side

rails for the body table are also in place.

Starting the construction of the body table. The 2x2 steel tubes will be

squared up and leveled, welded to the body, and will form a rigid frame for

making measurements, attaching temporary jackscrews to level the snout, etc.

It was easier to get the car up on the sawhorses and then build the table

under it.