This is an engine I originally built for someone in California. It got shipped there, then got sold to someone in North Carolina, then to Steve Grossen in Virginia. It was begun in 1996, and Steve took delivery of it in 2001. It had come back through the shop, re-done with different piston notches and some other changes, and now sits in Steve's basement, never having been fired up during its travels...

In 1996 there were no off-the-shelf Windsor stroker bits, so I used modified Chrysler rods, Chevy pistons, and an offset 400 crank. It's still a combination that works just fine.

As usual I didn't take nearly as many photos as I should have, so I've combined the original and rework photos to give a better idea of how things go together.

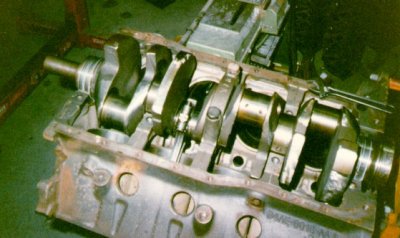

The rod cheeks were extensively lightened and all four crankpins were drilled

out to 1" for lightening and to make it easier to balance. It still took

heavy metal.

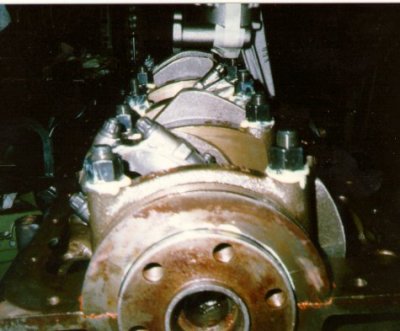

You can see the "snout ring" on the 430 crank has been cut off, to take a

Windsor lower sprocket. The nose also had to be shortened to keep it from

sticking past the washer flange on a Windsor balancer; that hasn't been done

yet in this photo.

The rods are Chrysler small block. The pin ends have been reduced to .927 Chevy size with Federal-Mogul bronze bushings. They have also been narrowed to 1" to clear the inside of the KB piston bosses. The big ends have been narrowed to fit the Ford width journals. The rod bearings also had to be narrowed a bit. I had purchased ARP WaveLoc bolts, but the shank diameter was almost .020" too large to go into the Chrysler holes. Talked with ARP tech support were inconclusive. I eventually bought a set of Direct Connection bolts and used the ARP nuts on them.

The bronze bushings were honed for floating pins and Spirolocs were used in

the pistons.

The brown stuff is what comes from living in "wetlands".

This episode directly led to my purchase of a Stewart-Warner crankshaft balancer, so I could do my own balancing.

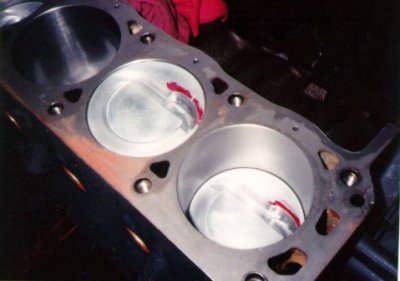

Hand cutting works fine, but it's time consuming. When I first built the

engine, I didn't have a piston vise. The second time around, I did, which

makes for a neater job.

The second time around, I balanced the engine again on my own machine.

===========================================================================

Parts List / Build Sheet

MAXIMUM OVERDRIVE RACING ENGINES

number: 0012, shipped 04/97

rework (new block, valve reliefs) shipped 05/01

engine: Ford 351 Windsor, 430 cubic inches

short block

for: Steve Grossen, King George VA

4.040 x 4.187 bore and stroke, 430 cubic inches

400M crank, Chrysler rods, 50oz 5.0 external balance

14cc dish KB169

65cc Ford D0OE 351W heads

9.12cc .043" head gasket

9cc .030 negative deck, extra valve notch, etc.

------

97.12cc

4.04 x 4.187 = 429.38 CID = 7073.61cc /8 = 879.70cc/cyl

879.7 / 97.12 = 9.06:1 CR

COMPONENTS ---------------------------------------------------------------

crankshaft:

400M Ford

mains 351W - std.

rods 360 Chrysler - .010"

balanced to 50oz 5.0 bobweight, heavy metal

oil slinger turned off

rod throws drilled for lightness

extensive grinding for lightening and balancing

profiled for piston, block, and oil pump clearance

snout cut back to 351W length

snout ring cut back for 351W timing sprocket

extra keyway cut for 351W timing sprocket (3/16 x 3/4 Woodruff)

new roller pilot bearing

pistons:

Keith Black KB169 hypereutectic

D-dish top with valve trough

additional valve reliefs cut for Brodix Track 1 heads, 2.02 intake

4.040" diameter

CBC2 ceramic coated tops

TLMB moly coated sides

single Spirolox pin retainers

standard KB wrist pins

rings:

.040" 1/16, 1/16, 3/16 Speed-Pro file fit moly

rods:

360 Mopar forgings

narrowed big ends

pin ends bushed down to SBC .927 pins, FM 1799V bronze

floating pins, .001"

oil hole drilled on top of rod

pin ends narrowed to 1", profiled round for lightness

Direct Connection rod bolts

ARP 12-point jet nuts

polished beams

oil holes point at pan rail (Mopar cylinder bank offset was opposite

Ford, chamfers matched up better that way, Ford oil holes

intersected with Mopar squirt holes so the oil stream didn't

point anywhere useful either way the rod went in)

standard-width Mopar bearings

block:

1974 351W

bored .040"

honed to .0015" piston/wall clearance

#600 wall finish

bottoms of bores and oil pan rails clearanced for long stroke

2 piece rear main seal

new core plugs

paint block (Dupli-Color Ford Blue)

#60 hole drilled below distributor gear

new cam bearings (Clevite 77)

TLMB moly coated main bearings

clearanced for stroker crank

Dorman main studs

Dorman main bolt washers

threads chased

lifter valley white Rust-Oleum

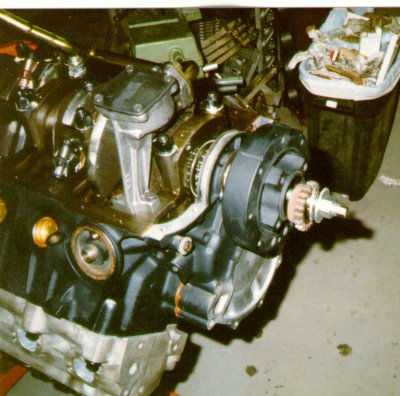

accessories:

V-belt, standard rotation timing cover

50oz 5.0 damper

timing pointer

timing pointer shows correct TDC

ARP flywheel bolts

Ford Motorsport 28 oz. billet steel 5.0 flywheel, drilled to 50oz

stock Ford front sump oil pan

stock Ford drain plug

high volume Melling oil pump, ground for crank clearance

oil pump bolts

stock oil pump pickup tube

new Melling oil pump drive rod

cam bolt, washer, and fuel pump eccentric

cam retainer plate, bolts

harmonic balancer bolt and washer

new Ford Motorsport timing chain set with indexable sprocket

crank keys

===========================================================================

assembly lubricants:

rod bearings: 30wt oil

rings: Unilube two stroke oil

cylinder walls: Mobil 1 5w30

piston skirts: Mobil 1 5w30

wrist pins: Mobil 1 5w30

main bolts - threads: ARP moly grease

main bolts - under head: moly grease

rod bolts: ARP moly lube

crankshaft rear oil seal: Mobil 1 5w30

===========================================================================

TORQUE SPECIFICATIONS -----------------------------------------------------

--------torque---------------spec-----------thread---lube------------------

rod bolts

torqued to 45 ft-lb 3/8-24 ARP moly lube

note: 1) step 1: 30 ft-lb

step 2: 45 ft-lb

main cap studs

torqued to 84 ft-lb 7/16-20 ARP moly lube

note: 1) use moly grease under bolt head

2) step 1: 50 ft-lb

step 2: 84 ft-lb (reverse pattern)

head bolts

(Ford spec 95-105) 1/2-13 oil

note: 1) use hardened washers, moly grease both sides of washer

2) block is blind tapped, no sealer needed

3) step 1: 50 ft-lb

step 2: 70 ft-lb (reverse pattern)

step 3: 100 ft-lb (mirror pattern)

4) if you use studs, torque readings will usually be much lower

5) if you use ARP bolts, DO NOT get the ones with the small hex; the

heads are so short they will strip and round off the second or

third time you take them out, or if your socket doesn't fit right.

Given these are 1/2" bolts the stockers will work fine.

damper (harmonic balancer) bolt

(Ford spec 70-90) 5/8-18 oil

note: 1) use automatic transmission fluid as lubricant when pressing damper

on

2) some people use sealer on the keyway to eliminate the chance of an

oil leak there.

flexplate bolts

(Ford spec 75-85) sealer

note: see drawing for pattern

intake manifold bolts

(Ford spec 23-25) 5/16-18 sealer

note: DO NOT OVERTORQUE. You can break these bolts right off by hand if

you're not careful. The bolts go into the head at a 45 degree

angle and the intake manifold makes enough of a wedge to lift the

heads right off the block! No fake. Unless there's some kind of

problem the intake won't leak even if the bolts are just past

finger tight.

exhaust manifold bolts

(Ford spec 18-24) 3/8-16 antiseize

note: use high temp antiseize if available

rocker studs (torque 40 ft-lb) 7/16-16 sealer

timing chain sprocket bolt

(Ford spec 40-45) 3/8-16 (Fel-Pro Grey Bolt Prep)

cam retainer plate

(Ford spec 9-12) 1/4-20 (Fel-Pro Grey Bolt Prep)

oil pan bolts

(Ford spec 7-9) 1/4-20 oil

(Ford spec 9-11) 5/16-18 oil

note: 11 ft-lb is "snug" with a nut driver; if you overtorque the bolts

and you're fortunate enough not to break them off in the block,

you'll probably warp the pan and it'll leak.

oil drain plug

(Ford spec 15-25) 1/2-20 oil

water pump bolts

(torque 12-18) 5/16-18 antiseize

timing cover bolts

(torque 12-18) 5/16-18 oil

1/4 NPT threaded oilway plugs Loctite Pipe Sealer With Teflon

or silicone sealer, Teflon pipe sealer

oil pump pickup

(Ford spec 9-11) 5/16-18 Loctite 242

oil pump cover plate

(Ford spec 9-11) 1/4-20 Loctite 242

oil pump body

(torque 30-35) 3/8-16 Loctite 242

spark plugs

18mm antiseize

bottom pulley to damper

(Ford spec 35-50) oil

valve cover

(Ford spec 3-5) 1/4-20 oil

fuel pump to timing cover

(Ford spec 19-27) 3/8-16 antiseize

fan to water pump

(Ford spec 12-18) 5/16-24 antiseize

carburetor to intake

(Ford spec 12-15) 5/16-18 antiseize

481 rod rotating

481 rod rotating

51 rod bearing

51 rod bearing

477 piston

145 pin

48 ring set

205 rod reciprocating

----

1943 grams bob weight

50 oz-in 5.0 balancer and flywheel

800 setup/650 spin

took heavy metal to balance

.03/.05 oz-in finish balance