This one was just a short block. .080-over 460 block, 4.200 stroked 460 crank, 240/Six rods, and custom Venolia pistons. John's finishing it up himself, and it'll power his Galaxie wagon.

Stroked crank just off the grinder. 2.124" rod journals, offset ground to

4.2" stroke. Started out as a standard 3.85" 460 crank.

Stroked crank just off the grinder. 2.124" rod journals, offset ground to

4.2" stroke. Started out as a standard 3.85" 460 crank.

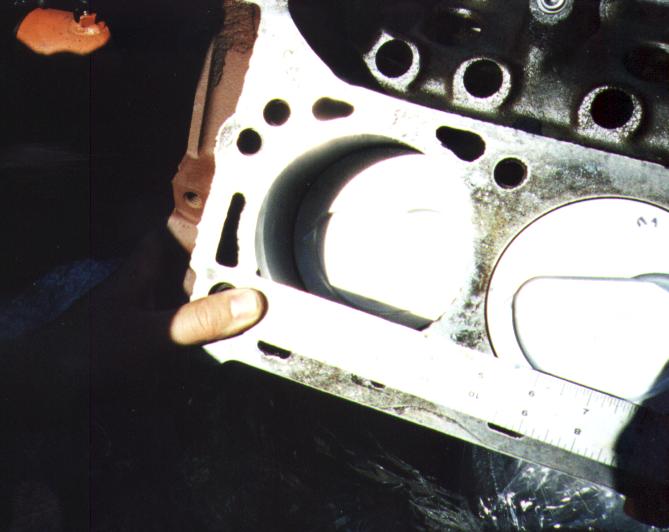

The piston sitting sideways in the 525's 4.440" bore is a standard 4-inch

forging for a 351W stroker. That extra .440" bore looks more impressive this

way, doesn't it?

The piston sitting sideways in the 525's 4.440" bore is a standard 4-inch

forging for a 351W stroker. That extra .440" bore looks more impressive this

way, doesn't it?

Cam plug and driver.

Cam plug and driver.

Installing cam bearings. Each bearing is a different size, with the smallest

in front, largest in back. They have to be installed in the correct positions

and rotated to match the oil holes in the block.

Installing cam bearings. Each bearing is a different size, with the smallest

in front, largest in back. They have to be installed in the correct positions

and rotated to match the oil holes in the block.

Gapping the rings. 4.440" moly rings are $150 a set! Each ring is file-fit

to match its cylinder.

Gapping the rings. 4.440" moly rings are $150 a set! Each ring is file-fit

to match its cylinder.

Narrowed 240/Six connecting rod being heated so the piston can be hung.

Narrowed 240/Six connecting rod being heated so the piston can be hung.

The front of the block had a crack in one of the timing cover bolt holes. I

ground the boss off, welded a block of mild steel on, and drilled and tapped a

new hole.

The front of the block had a crack in one of the timing cover bolt holes. I

ground the boss off, welded a block of mild steel on, and drilled and tapped a

new hole.

This picture came out really dark for some reason.

The big oil hole connects to the crossover passage from the oil pump to the

main oil gallery. Oil comes in there. The little hole goes to the front cam

bearing, with a diagonal drilling to feed the distributor shaft bore.

The big oil hole connects to the crossover passage from the oil pump to the

main oil gallery. Oil comes in there. The little hole goes to the front cam

bearing, with a diagonal drilling to feed the distributor shaft bore.

Here's how the cam/distributor oil hole gets fed by oil going around the

groove in the bearing... oops, it doesn't! The block was either not drilled

properly, or the replacement bearings had an incorrect groove. Paranoia is

your friend. Really.

Here's how the cam/distributor oil hole gets fed by oil going around the

groove in the bearing... oops, it doesn't! The block was either not drilled

properly, or the replacement bearings had an incorrect groove. Paranoia is

your friend. Really.

A minute with the Dremel tool and the oil passage is opened up.

A minute with the Dremel tool and the oil passage is opened up.

Pistons and rods hung, rings installed, all racked up and ready to go. Nifty

PVC stand came from a pawn shop in Memphis for $10!

Pistons and rods hung, rings installed, all racked up and ready to go. Nifty

PVC stand came from a pawn shop in Memphis for $10!

The pistons are ceramic coated on top and moly coated on the sides. Rods have

ARP bolts.

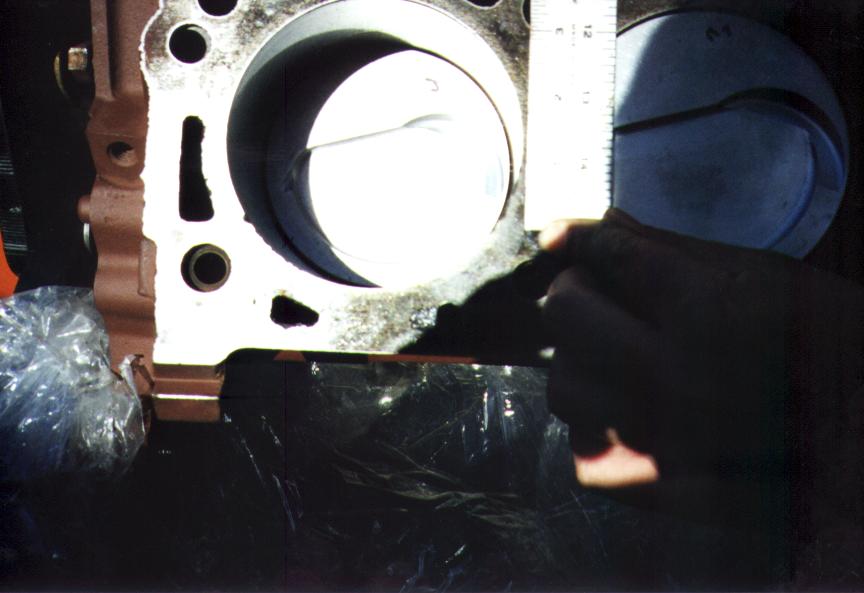

Here we go, ready for assembly. Cleaned, threads chased, cam bearings

installed.

Here we go, ready for assembly. Cleaned, threads chased, cam bearings

installed.

I just love it when a plan comes together...

I just love it when a plan comes together...

Stretching the rod bolts to .0062" with the dial indicator.

Stretching the rod bolts to .0062" with the dial indicator.

And we're done! The bore and stroke are impressive compared to the small

blocks I usually do...

And we're done! The bore and stroke are impressive compared to the small

blocks I usually do...

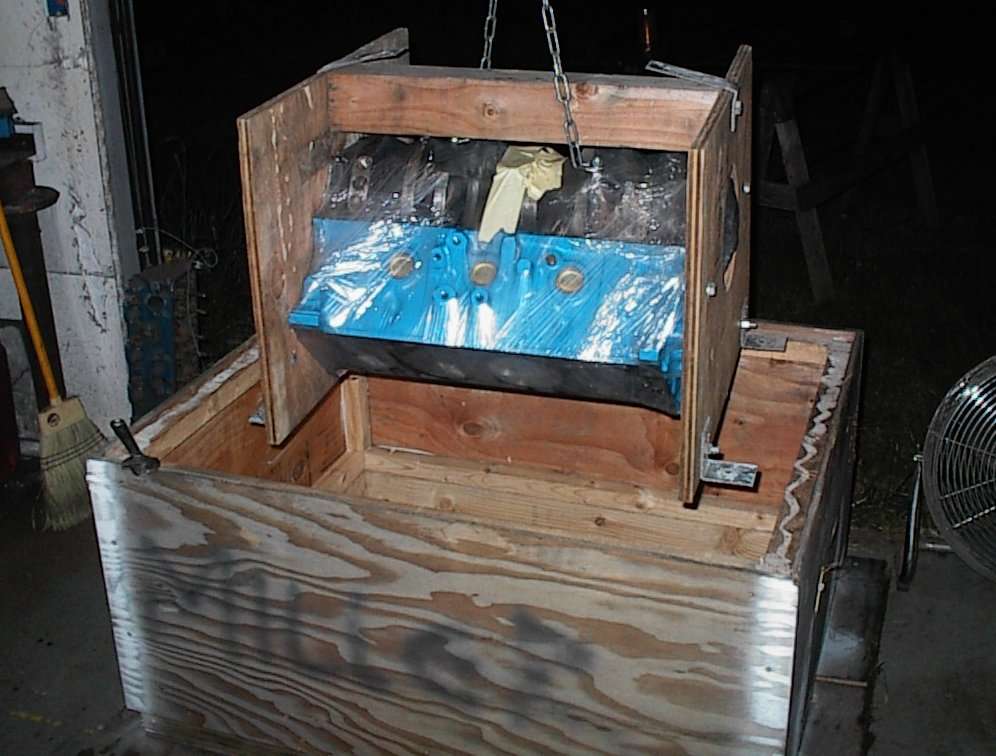

First I built a subframe up on a cut-down pallet and sat the stretch-wrapped

engine down on that. Wires and chocking blocks were added to keep it in

place.

First I built a subframe up on a cut-down pallet and sat the stretch-wrapped

engine down on that. Wires and chocking blocks were added to keep it in

place.

Then I built a 2x2 frame and added the cover panels, and painted it all

flourescent safety orange. It looked radioactive in the back of the truck at

the freight terminal, out in the sunlight. The freight clerk even commented

on how nice the crating job was.

Then I built a 2x2 frame and added the cover panels, and painted it all

flourescent safety orange. It looked radioactive in the back of the truck at

the freight terminal, out in the sunlight. The freight clerk even commented

on how nice the crating job was.

Initial view of the crate as John saw it.

Initial view of the crate as John saw it.

Apparent forklift puncture?

Apparent forklift puncture?

Opposite side of crate missing - block pushed thru by fork? The slimeballs

tried to claim the short block was "improperly crated." New Detroit short

blocks are just strapped to a pallet with a few laths stapled together as a

sort of mesh cover; my crate was a hell of a lot better than that.

Opposite side of crate missing - block pushed thru by fork? The slimeballs

tried to claim the short block was "improperly crated." New Detroit short

blocks are just strapped to a pallet with a few laths stapled together as a

sort of mesh cover; my crate was a hell of a lot better than that.

One deck, in plastic

Other deck, in plastic

Bore damage.

Bore damage.

One of the forks dinged this bore fairly deeply.

One of the forks dinged this bore fairly deeply.

I had a car in the shop that couldn't be moved, so I disassembled John's new

crate in the back of my truck. As soon as I got the lid off I was confronted

by a mass of rust. John, being from California, hadn't thought to re-wrap the

short block in plastic before returning it, but it likely wouldn't have

mattered, since it looked like the shipper had dragged it through a lake; the

cylinders were half-full of water.

I had a car in the shop that couldn't be moved, so I disassembled John's new

crate in the back of my truck. As soon as I got the lid off I was confronted

by a mass of rust. John, being from California, hadn't thought to re-wrap the

short block in plastic before returning it, but it likely wouldn't have

mattered, since it looked like the shipper had dragged it through a lake; the

cylinders were half-full of water.

I was so disgusted I just rolled the damned thing off the tailgate and onto

the ground. The crankshaft miked out straight, all the rust wire wheeled off

the crank and rods, but the cylinder bores were pitted so badly it would have

passed some oil.

I was so disgusted I just rolled the damned thing off the tailgate and onto

the ground. The crankshaft miked out straight, all the rust wire wheeled off

the crank and rods, but the cylinder bores were pitted so badly it would have

passed some oil.

I located, bored, and prepped a replacement block.

I located, bored, and prepped a replacement block.

The re-blocked short block being inserted in John's Crate From Hell. This

time it made it to California okay.

The re-blocked short block being inserted in John's Crate From Hell. This

time it made it to California okay.

John Miller's 520 Ford Stroker

4.440 bore, 4.200 stroke, 520.23 cubic inches

==========================================================================

Block:

460 Ford

4.440 bore

new cam bearings (fit checked with stock cam)

new freeze and oil plugs

Rust-Oleum Rusty Metal Primer

decks flat within .001

note: oil plugs are straight thread

two piece rear main seal

#600 bore finish

.0045" piston clearance

Crankshaft:

460 Ford

4.200 stroke

standard 460 main bearings

standard 240/Six rod bearings

balanced

flexplate holes chased

.0015" clearance rods

.002" clearance mains

Rods:

Ford 240/6

6.79" long

Magnafluxed

resized

ARP bolts

stretched to .0065" w/ARP lube

pressed pins

oil squirt holes all point to cam

side clearance .010-.015

Pistons:

Venolia custom forged

30cc dish top

4.440 nominal bore

1/16 1/16 3/16 ring grooves

240/6 .975" pin size

.060 pin offset

note: looking at front of engine, pins are offset to the

left, or thrust, side

sandblasted

Tech Line TLML anti-friction coated sides

Tech Line CBC2 thermal barrier coated tops

===========================================================================

Rings:

Speed-Pro moly

widths 1/16 1/16 3/16

file fit

gaps .016 top, .014 second, .035 oil nominal

recommended gaps .010-.020 top, second, .015-.055 oil

3-pc oil rings

Balance:

Stewart-Warner Model 2000 Industrial Balancer

figures:

692 g one piston

148 g one pin

188 g one rod small end

549 g rod big end

549 g rod big end

53 g rod bearing

53 g rod bearing

6 g oil allowance

----

1149 g bob weight

750 RPM setup speed

600 RPM balance speed

residual imbalance:

.01 oz-in front

.025 oz-in rear

neutral balance

split balance - crank balanced alone, damper and flexplate separately

Other:

windage tray installed

stock damper, damper spacer, Woodruff key, flexplate provided

crated for shipping

build book

===========================================================================