The Big Block Chevrolet V8s

366 - 396 - 402 - 427 - 454 - 501 - 502

This page convers only unusual or exotic big block Chevy bits.

Big Block Engines

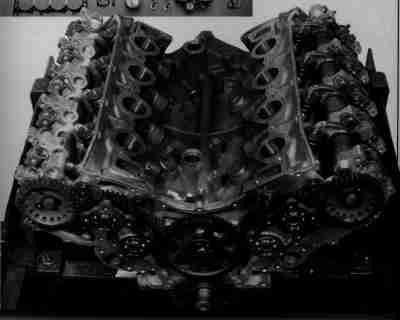

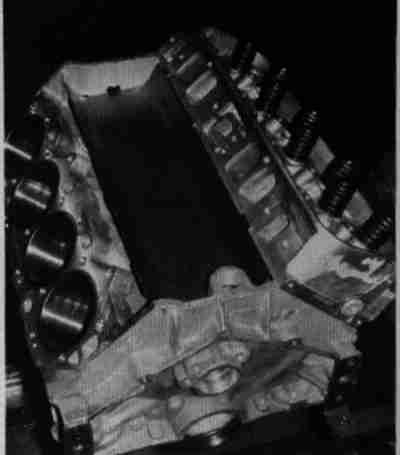

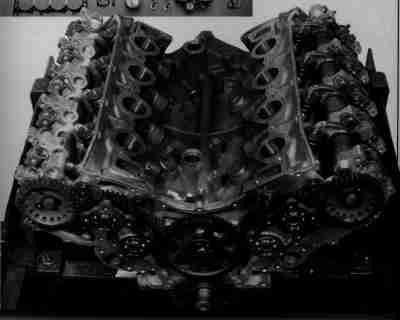

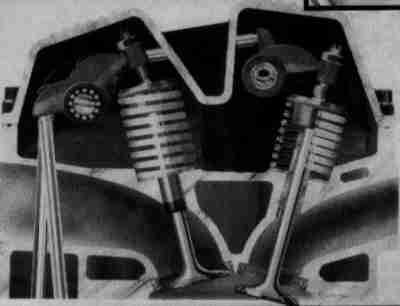

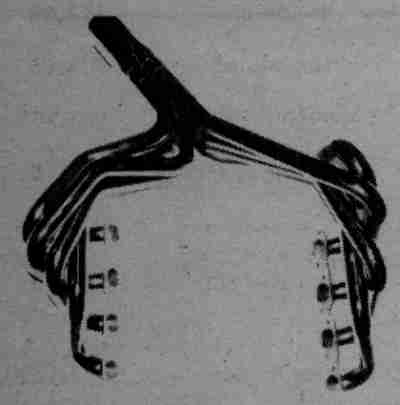

This aluminum single overhead camshaft 427 was built sometime before 1969.

Note the hairpin type helper springs on the rocker arms. It would seem the

block valley was designed to be open instead of covered by a manifold.

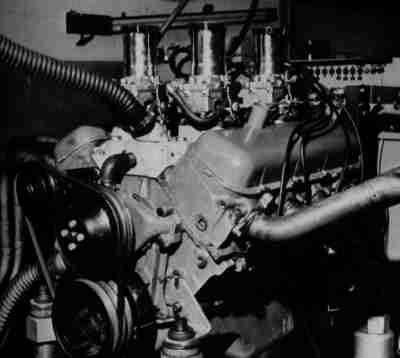

Falconer-Dunn 489-inch MkIV on tall-deck truck block, circa 1972. It uses

Chevy ZL-1 aluminum heads, ultra-rare Moon intake, and Bosch mechanical fuel

injection. It was conservatively rated at 600HP.

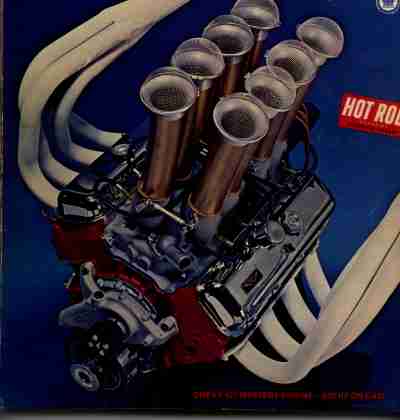

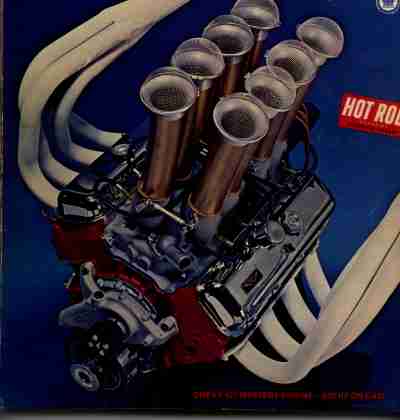

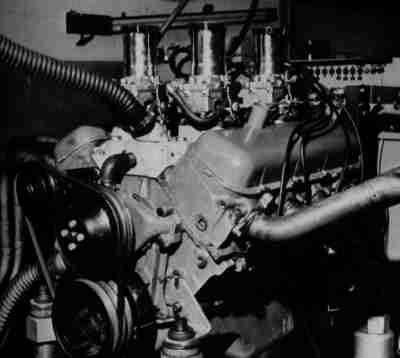

This Bartz-built 427 was done in 1968. Note the slightly curved stacks on the

Hilborn mechanical fuel injection. That appears to be one of GM's skunkworks

dry sump pump timing covers peeking out under the aluminum water pump.

Big Block Heads

The Mk IV engines wound up with an odd head bolt pattern due to its

combination of "long" and "short" intake ports. The intakes are paired; the

exhausts are evenly spaced. To do this, Chevrolet used two different types of

intake port on each head.

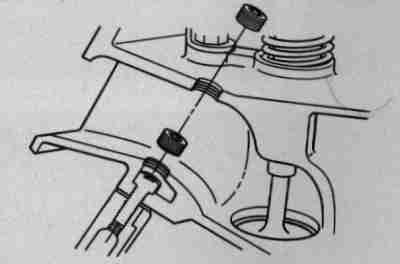

The ZL-1 added extra bosses on the valley side and extra head bolts to even

out the clamping load. Since the inlet port ran right over the spot the bolt

needed to go, Chevrolet engineers put a plug in the top of the port and put

the bolt head in the port.

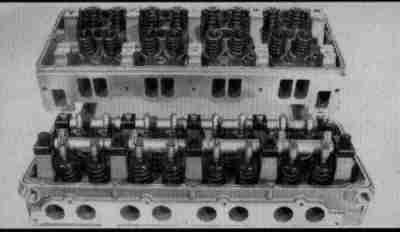

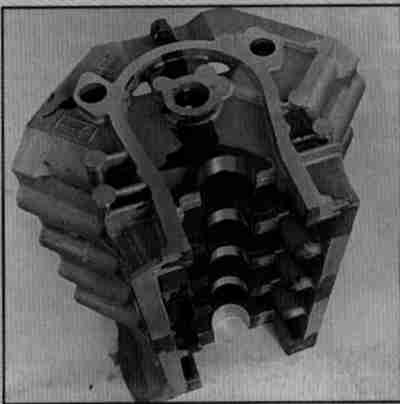

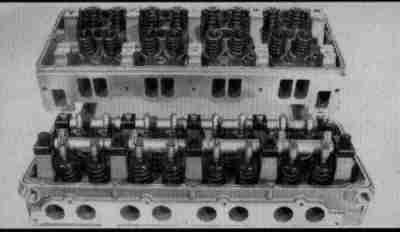

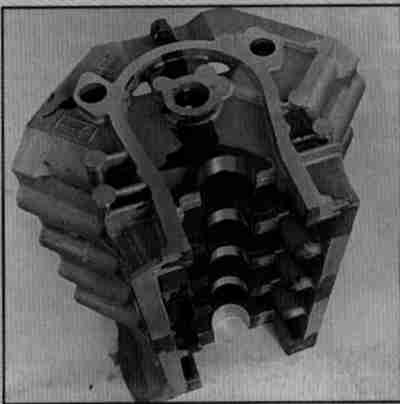

These 4-valve pushrod heads were available from Thunder Power in the early

'90s. The heads, intake, and assorted bits cost around $8,500 in 1992. The

manufacturer said a big block with their heads would fit in a C4 Corvette.

The complete Thunder Power kit. It's easier to understand why it cost so much

when it's all spread out like this.

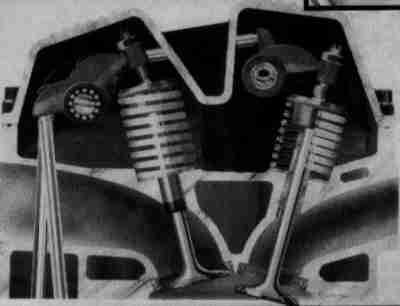

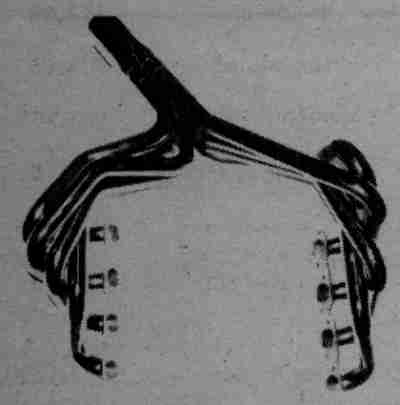

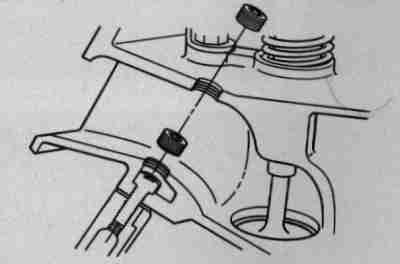

Stylized PR drawing of the Thunder rocker arm setup. It's not as strange as

it looks; very similar systems have been used by Maserati, BMW, and Bristol,

among others.

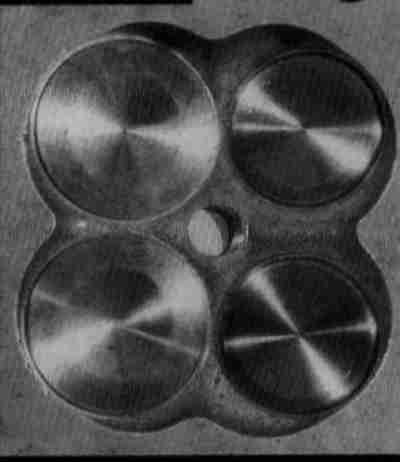

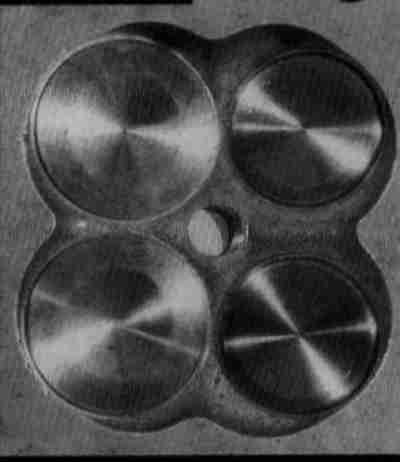

Standard Cosworth-style cloverleaf combustion chamber. low included valve

angle. 1.75/1.50 valves were standard, though you could fit 1.875/1.625s if

you wanted.

Two intake and exhaust ports per cylinder. The 16-port intake came with the

kit; Thunder sold 16-to-8 port header flanges separately.

Here they are in a big block C4 Corvette conversion. They don't offer any

more passenger-side A-arm clearance than the stock heads, but at least they're

no larger either.

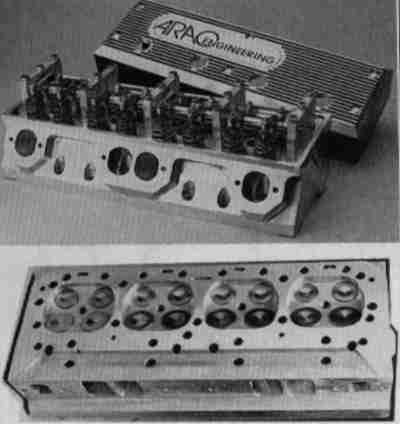

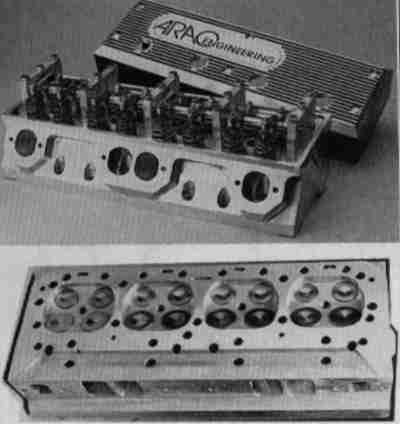

These Arao heads were available in the early '90s. Unlike the Thunder Power

heads, they accepted stock manifolds, pushrods, and other bits.

Big Block Intakes

Cross-ram intake with six two barrels, circa 1967.

This 427 carries four Rochester two barrel carburetors on an aftermarket

intake, circa 1966. Multiple carbs were the only way to go when the largest

four barrels of the day flowed only 650 CFM or so.

The stacks on this fuel injection intake are 21-3/4 and 18-1/2" long, measured

from the manifold faces. However, the big block's long/short port runners

make each stack the same length from the valve to the end of the stack.

If all the stacks were made the same length from the manifold base it would

just spread the torque curve out a bit.

Weiand makes these spacers to put regular intakes on +.400" truck-deck-height

MkIVs. Taller-deck engines usually use custom sheet aluminum intakes.

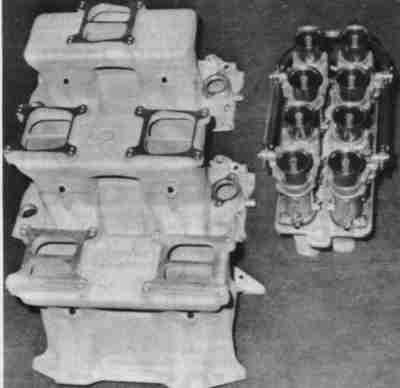

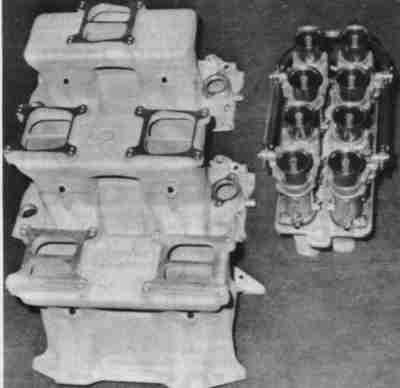

Offenhauser tunnel ram with interchangeable tops. Single or dual quad, Holley

or spread bore, four Weber IDAs, or (not pictured here) single Holley

Dominator.

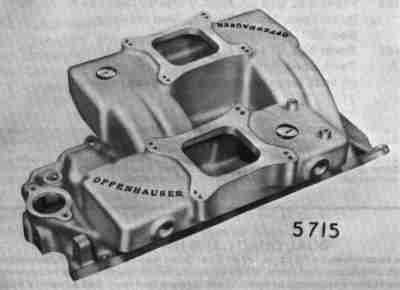

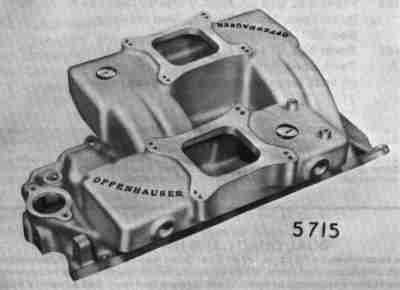

Offenhauser cross-ram intake from the mid '60s. Still available too. Most

people go straight to the tunnel ram intakes, but the cross-rams have a better

shot through the port/manifold interface.

Big Block Oiling System

This sheet steel tray kept hot oil from the bottom of the intake manifold on

ZL-1 aluminum 427s.

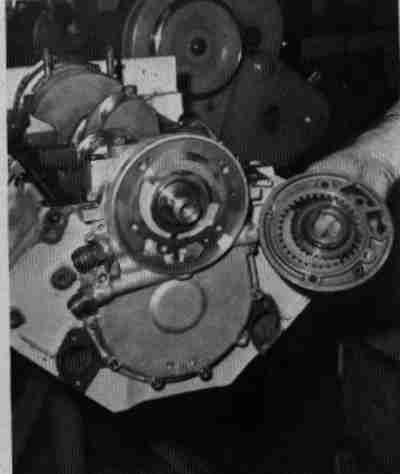

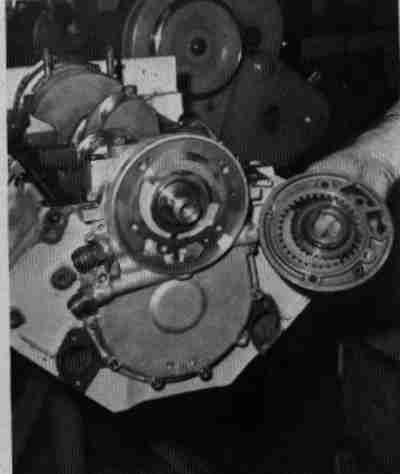

This ultra-trick dry sump setup was produced by GM and given out to people like

Bruce McLaren and Smokey Yunick. It used an automatic transmission pump as

the pressure pump and kept the original oil pump as a scavenge pump. The rise

of (relatively) inexpensive multistage pumps in the aftermarket made these

pieces obsolete.

Big Block Blocks

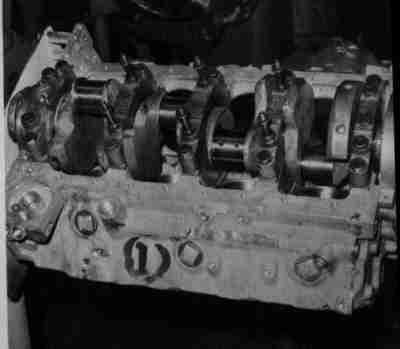

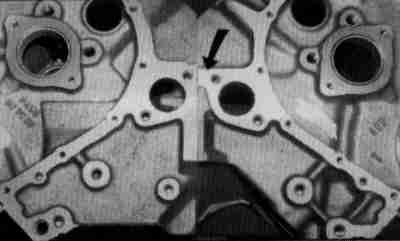

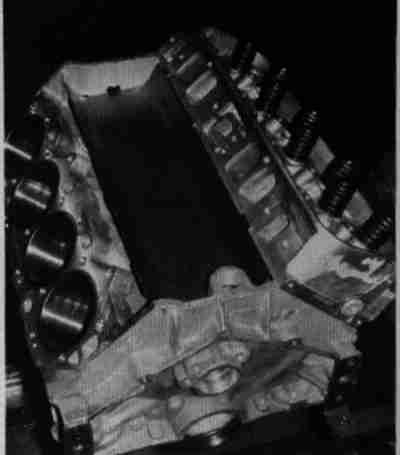

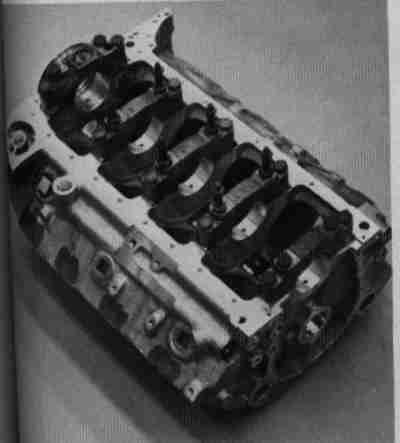

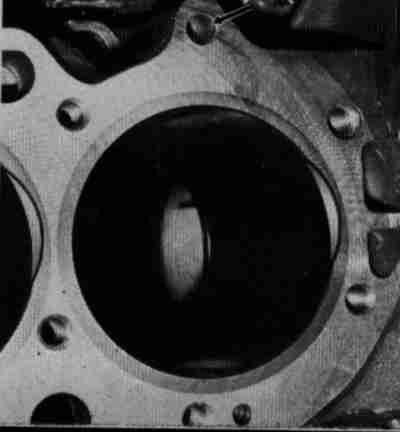

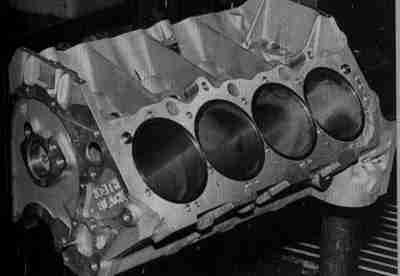

Here it is - the 1969 ZL-1 aluminum 427 block, as used by McLaren and others.

Only a few dozen of these ever made it to the street. Cast iron sleeves were

installed after the block was cast. Note notches at top of sleeves for intake

valve unshrouding.

Screw-in core plugs won't fall out in competition. Cast iron caps were

standard. Note provision for oil cooler lines on oil filter boss.

All the Mk IV engines were side oilers. The aluminum blocks had larger oil

galleries and provision for feeding the main rail directly from a dry sump

pump via the boss in front of the filter adapter.

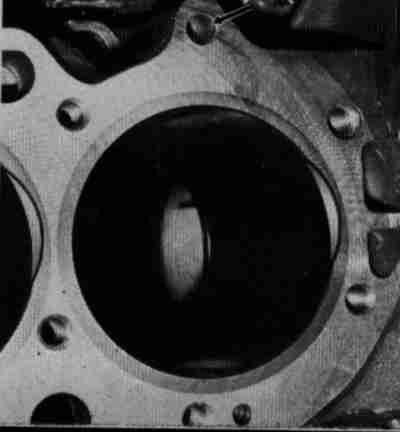

Close-up of the ZL-1's intake valve unshrouding notch. Also note the extra

head bolt boss indicated by the arrow.

Olds was heavily involved with drag racing when GM pulled their engine

production line out from under them. Limited to the "corporate" big block

Chevrolet, Olds engineers developed the "Drag Race Competition Engine", or

DRCE.

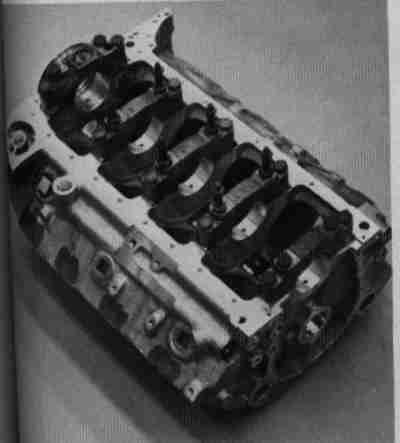

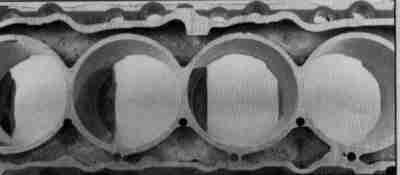

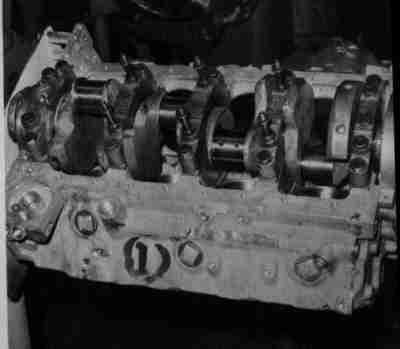

This is a late (1992) semifinished DRCE with deep skirts to reinforce the

lower end. Most of these were machined to take cross-bolted main caps. The

DRCEs could be bored to 4.625 without filling the water jackets.

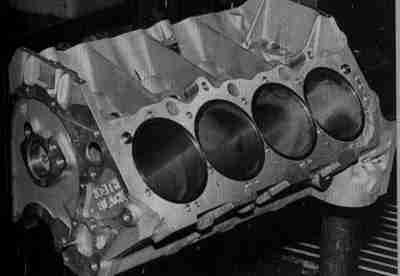

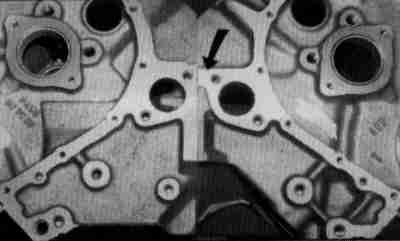

Here's a standard 9.80" MkIV block on the left and the 10.20" tall deck

366/427 truck block on the right. Arrow points to the telltale pad of metal

over the water pump boss. All tall-deck 427s had four bolt mains.

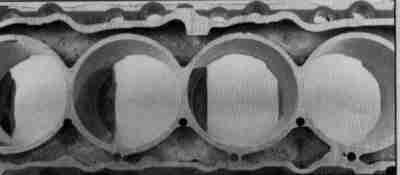

1992 MkIV Bowtie block with siamesed bores. Note the lower row of head bolts

anchor into the cylinders. They can pull the bore out of round when the head

is torqued down. That's why most high performance engine builders use torque

plates.

There have been many other manufacturers of aluminum big block Chevys besides

Chevrolet. This one is from Keith Black. If you're buying a used aftermarket

block, make sure it has provisions for a wet sump if you need one, and check

the deck height, as many of them were taller than stock. Oh, and water

jackets! Some were cast solid with no water jackets for drag racing.

Donovan makes their aluminum blocks in a variety of configurations and deck

heights. They also make them with Chevrolet, Oldsmobile, or Pontiac head bolt

patterns. Again, it pays to make sure of what you're buying when you're

purchasing an aluminum block!

Butrick Precision & Service made a selection of aftermarket MkIVs circa 1986.

As usual, whatever deck height you wanted, your choice of cast iron, aluminum,

or... magnesium! Iron blocks weighed 305 pounds, aluminum 134, magnesium only

74!

Big Block Valvetrain

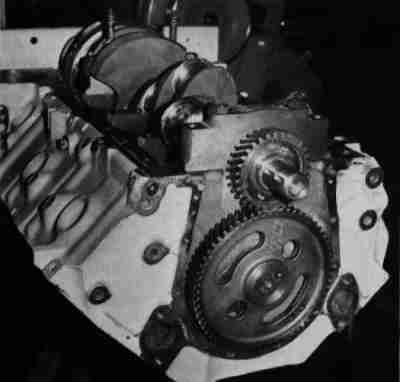

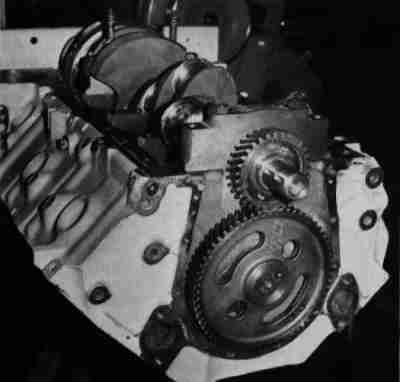

This two-gear cam setup came out of the GM heavy truck parts bin. It was

originally designed for the 366-ci truck big blocks. A reverse-rotation cam

was required.

Big Block Rotating Assembly

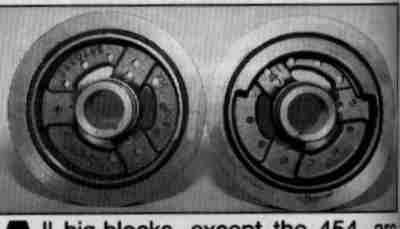

The 366, 396, 402, and 427 are internally balanced. If you find an engine

with a counterweighted balancer or flywheel, it's 454 inches or larger.

Big Block Exhaust Manifolds

180-degree Schoenfeld oval track header for for Mark IV.

-EOF-