This is a 302 stroked to 351, old-school style circa 1995. 5.0 roller block, cut-down 351 Cleveland crank, 2.3 Pinto rods, Chevy pistons, and D0OE 351W cylinder heads. Lots of machine work that we don't have to do nowadays.

Unfortunately, I didn't get photos showing the coated pistons, combustion chambers, or valves, or the conversion to 1.94/1.50 Chevy valves, or most of the rod work, or degreeing the cam, or... the pictures were taken with a 35mm camera, at about a dollar a shot by the time you figure film and developing. Now that digital pictures are basically free, I still have to remember to reach for the camera occasionally.

More details on the crankshaft work can be seen at:

http://www.bacomatic.org/~dw/302strok/crank.htm

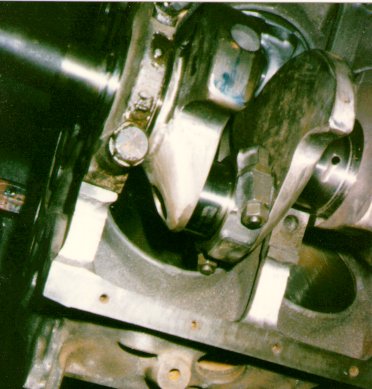

Checking for counterweight clearance again. The rod throws still haven't been

lightened yet, but the crank fits in there. The counterweights had to be cut

down over an inch, then "footballed" to clear the pistons at TDC.

Checking for counterweight clearance again. The rod throws still haven't been

lightened yet, but the crank fits in there. The counterweights had to be cut

down over an inch, then "footballed" to clear the pistons at TDC.

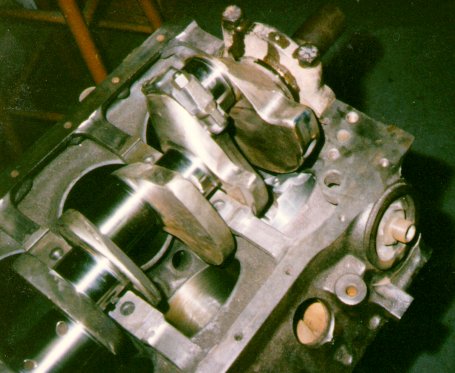

Crank is almost finished. It's sitting in a 289 block in this photo. Note

the rod bolt won't clear the bottom of the bore. Contrary to popular belief,

the cylinders of the 289, 302, and 5.0 are all the same length.

Crank is almost finished. It's sitting in a 289 block in this photo. Note

the rod bolt won't clear the bottom of the bore. Contrary to popular belief,

the cylinders of the 289, 302, and 5.0 are all the same length.

Yep, we're done! It spins fine now. Too bad those pesky rod bolts are

swinging out into the bottoms of the cylinders... a little grinder work will

take care of that. The pan rail had to be notched by the starter, and the oil

pump boss fettled for clearance.

Yep, we're done! It spins fine now. Too bad those pesky rod bolts are

swinging out into the bottoms of the cylinders... a little grinder work will

take care of that. The pan rail had to be notched by the starter, and the oil

pump boss fettled for clearance.

The 3.5" stroker crank next to a lightened 302 crank. Hard to tell the

difference just looking, eh?

The 3.5" stroker crank next to a lightened 302 crank. Hard to tell the

difference just looking, eh?

Here's a stock 351 Cleveland crank next to the cut down crank. Note the

difference in outside diameter.

Here's a stock 351 Cleveland crank next to the cut down crank. Note the

difference in outside diameter.

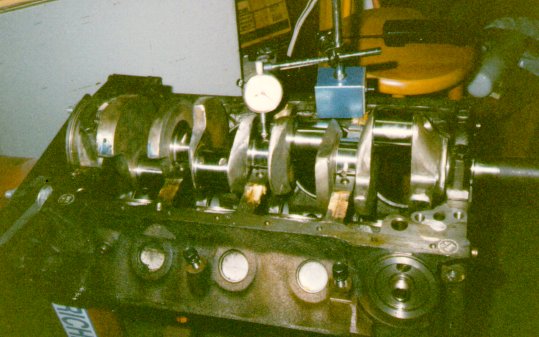

Checking the crank for straightness. It was dead nuts.

Checking the crank for straightness. It was dead nuts.

Finished, cleaned, and ready to install. There are approximately sixty hours

of labor, plus balancing charges, to get to this point.

Finished, cleaned, and ready to install. There are approximately sixty hours

of labor, plus balancing charges, to get to this point.

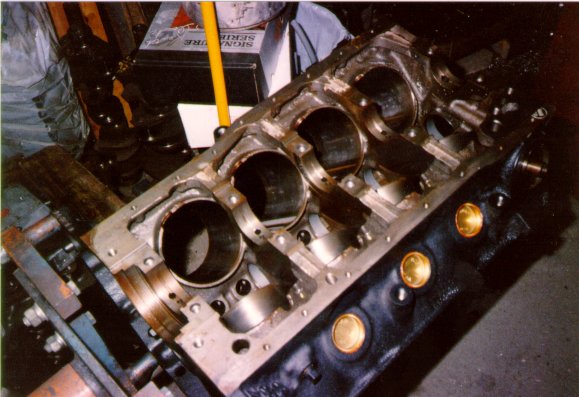

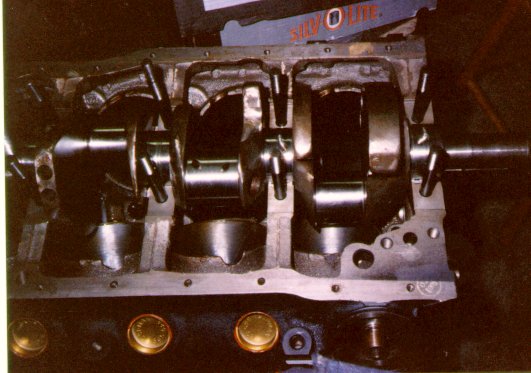

5.0 block ready to receive its new crank. Notice notches in cylinder skirts

and grooved main webs.

5.0 block ready to receive its new crank. Notice notches in cylinder skirts

and grooved main webs.

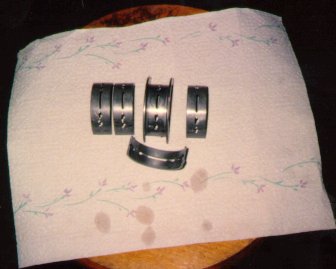

Here are the modified main bearings to match the main webs. This increases

the oil flow to the connecting rods.

Here are the modified main bearings to match the main webs. This increases

the oil flow to the connecting rods.

The crank is settled into its final resting place. ARP main studs will hold

the caps down.

The crank is settled into its final resting place. ARP main studs will hold

the caps down.

Rod pin end boring fixture on the milling machine. Spud held in collet aligns

centerlines. It was about 4AM when I was doing this, during an electrical

storm.

Rod pin end boring fixture on the milling machine. Spud held in collet aligns

centerlines. It was about 4AM when I was doing this, during an electrical

storm.

Boring the pin ends from .912 to .922. Rod hone will take them the rest of

the way to .925/.9255, to give a .0015-.002 interference for Chevrolet wrist

pins.

Boring the pin ends from .912 to .922. Rod hone will take them the rest of

the way to .925/.9255, to give a .0015-.002 interference for Chevrolet wrist

pins.

I widened the rod journals on the crank, which is a long and involved hassle,

but the 2300 rod bearings didn't need to be narrowed. Note the bearings sit

in the center of the rods; not all OEM rods do this, for some reason.

I widened the rod journals on the crank, which is a long and involved hassle,

but the 2300 rod bearings didn't need to be narrowed. Note the bearings sit

in the center of the rods; not all OEM rods do this, for some reason.

Stroke is a full 3.5 inches. Since the block has a stock bore, displacement

is 351 cubic inches.

Stroke is a full 3.5 inches. Since the block has a stock bore, displacement

is 351 cubic inches.

Tightening ARP rod bolts by stretch. Chalk mark on damper indicates top dead

center, which was about 90 degrees from the mark on the damper. I cut a new

mark into the damper when I degreed the cam.

Tightening ARP rod bolts by stretch. Chalk mark on damper indicates top dead

center, which was about 90 degrees from the mark on the damper. I cut a new

mark into the damper when I degreed the cam.

Custom-length TFS pushrods were required with the combination of D0OE heads,

roller cam, and Competition Cams steel rockers. Notice the wipe mark on the

valve stem, ARP head bolts, guide plates, and 7/16 screw-in studs.

Custom-length TFS pushrods were required with the combination of D0OE heads,

roller cam, and Competition Cams steel rockers. Notice the wipe mark on the

valve stem, ARP head bolts, guide plates, and 7/16 screw-in studs.

It's finally done. Shipping frame was assembled from bits of scrap lumber;

engine was air-freighted from Little Rock to San Jose in an aluminum

container.

It's finally done. Shipping frame was assembled from bits of scrap lumber;

engine was air-freighted from Little Rock to San Jose in an aluminum

container.