Sean Korb's 375 Windsor Stroker

This page: www.bacomatic.org/~dw/dehaven/dehaven.htm

Main page: http://www.bacomatic.org/~dw/index.htm

Last Updated: 6 Sep 2003

Author: Dave Williams; dlwilliams=aristotle=net

This 375 Windsor was originally built for David DeHaven's early Mustang. For

various reasons it took a long time to finish this one. I had to make a bunch

of tools, some parts had been discontinued, some parts had been updated and no

longer fit, and some were just plain bad. Plus a lot of plain old weird

stuff kept happening.

The engine finally got finished in February '01. Dave and I met in a cold,

windy Denny's parking lot in Missouri and wrestled the completed engine, two

Honda motorcycle engines, and assorted "stuff" from my truck to his.

In February 2003 David got Pantera lust, sold his Mustang project, and

sold the 379 to Sean Korb, who is going to put it in his '68 Cougar.

Here's the core and assorted bits as they came from the core yard.

Here's the core and assorted bits as they came from the core yard.

The "coffin" in the background is an old waterbed frame; part of it became my

engine run stand later. The "garbage can" is the safety shield from my Coats

spin balancer. Like most ill-designed "safety" equipment it was more hassle

than it was worth. Coats thought they made it nonremoveable by welding the

hinges to the main machine frame. That took only a few minutes with the air

cutoff tool...

Left to right:

Left to right:

351 Windsor rod, 5.95" long, takes 2.311" bearing, .912" pin

360 Chrysler rod, 6.125" long, takes 2.130" bearing, .965" pin

350 Chevy rod, 5.7" long, takes 2.100" bearing, .927" pin

A better view of the relative rod lengths. The Chrysler rod has more meat on

the big end and a beefier cap than the other two.

A better view of the relative rod lengths. The Chrysler rod has more meat on

the big end and a beefier cap than the other two.

Narrowing the big ends on the milling machine. The Chrysler rods are

considerably wider than the Ford crank journals.

Narrowing the big ends on the milling machine. The Chrysler rods are

considerably wider than the Ford crank journals.

I had done several engines with Chevy pistons and Chrysler rods before. The

Federal-Mogul master catalog had a listing for a bronze pin bushing that fit

almost perfectly - hone the pin end out a bit, drive the bushing in, then hone

the bushing to fit.

I had done several engines with Chevy pistons and Chrysler rods before. The

Federal-Mogul master catalog had a listing for a bronze pin bushing that fit

almost perfectly - hone the pin end out a bit, drive the bushing in, then hone

the bushing to fit.

Federal-Mogul stopped making the bushing, and I couldn't find anything else

close. Since these rods didn't have to be set up for floating pins, I decided

to use 1018 steel tubing instead. I made a lathe fixture to hold the thinwall

tubing round while turning then OD, another to hold it for turning the ID, and

drove the bushings into the rods with a hefty .005" interference fit. I

thought nothing short of dynamite would remove them. I took them to the rod

machine and honed the pin ends to .925" for .002 interference on Chevy pins.

I heated the first rod on the heating fixture, swung it over to the piston,

already waiting in its locating fixture, and... the interference fit bushing

fell out on the floor and rolled under the bench. WTF? The outside expanded

as expected with the heat; for some reason, the bushing didn't. When I told

some other shop guys about it they got big laughs, "yeah, that always

happens." I took the MIG and tack welded the bushings in place, ran them back

over the honing mandrel to make sure they were still round, and then started

assembling the rods and pistons.

The Chrysler rods are good parts, but somewhere along the line I got the idea

one of them was bent. I scouted every other shop within 75 miles and couldn't

find one with a rod checker, so I designed and built my own, accurate to

within .00025". Two fixtures were required. This first one makes sure the

hole is perpendicular to the sides of the big end.

The Chrysler rods are good parts, but somewhere along the line I got the idea

one of them was bent. I scouted every other shop within 75 miles and couldn't

find one with a rod checker, so I designed and built my own, accurate to

within .00025". Two fixtures were required. This first one makes sure the

hole is perpendicular to the sides of the big end.

Since I already had some of the pistons hung I made it so I could check rods

with the pistons on them.

Piston vise, flycutter, and piston. Federal-Mogul now ships Speed-Pro pistons

in TRW boxes. There's nothing wrong with Speed-Pro pistons... except the TRW

valve reliefs in 350 Chevy pistons will clear Ford valves and Speed-Pro

pistons won't.

Piston vise, flycutter, and piston. Federal-Mogul now ships Speed-Pro pistons

in TRW boxes. There's nothing wrong with Speed-Pro pistons... except the TRW

valve reliefs in 350 Chevy pistons will clear Ford valves and Speed-Pro

pistons won't.

I found this out during the trial fit. The crank, cam, one rod, and a piston

were installed, with one of my special undersize wristpins. The exhaust

valves overlapped the reliefs by .050" or so.

I needed a piston holding fixture anyway, so I made one and flycut the exhaust

valve reliefs for proper clearance.

During the build, the price of forged Chrysler pistons went from $180 to

almost $400, and the $125 Chevy pistons went to $250. I bushed the Chrysler

rods to take Chevy pistons and used them to save money.

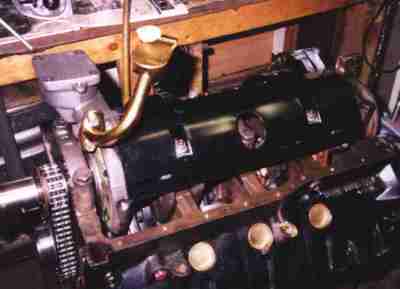

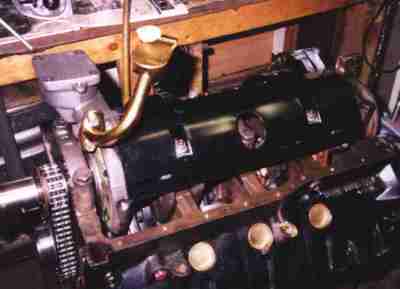

We're on final assembly here. Well, it was supposed to be. With the main

caps torqued down the crank turned with great difficulty. The crank was

standard size on the mains; I had just ass-umed it was straight. It was bent

almost .005" TIR on the #2 main. Everything had to come back apart, the crank

had to be straightened and ground .010" undersize on the mains, and new

bearings purchased.

We're on final assembly here. Well, it was supposed to be. With the main

caps torqued down the crank turned with great difficulty. The crank was

standard size on the mains; I had just ass-umed it was straight. It was bent

almost .005" TIR on the #2 main. Everything had to come back apart, the crank

had to be straightened and ground .010" undersize on the mains, and new

bearings purchased.

I put the newly turned crank in the block on its new bearings, snugged the

main caps down, and... it wouldn't turn! WTF? The Plastigage and micrometer

relayed the awful truth. This block, the third block, the one that was

Magnafluxed, torque plate honed, and detailed to the nines... this block had

the wrong main caps! Not only did they not make a round bore, they didn't fit

tightly in their cutouts. Damn!

I put the newly turned crank in the block on its new bearings, snugged the

main caps down, and... it wouldn't turn! WTF? The Plastigage and micrometer

relayed the awful truth. This block, the third block, the one that was

Magnafluxed, torque plate honed, and detailed to the nines... this block had

the wrong main caps! Not only did they not make a round bore, they didn't fit

tightly in their cutouts. Damn!

I dug through my extensive cap collection and wound up having to pick a couple

of those, plus sacrifice a good Windsor block to get five caps that were

close. But they weren't quite close enough. I had to haul it off to Little

Rock and pay $125 to have it align bored.

AB was driving my truck, so I pulled the passenger seat out of the Escort and

rolled the block into the floor from the hand truck. It's actually easier to

haul a block around in the Escort than it is to back the truck into the shop

where the chain hoist is.

Okay, the crank is back in, bearing clearances are fine, everything is round

or straight as it's supposed to be, and the block has been washed and dried

for the dozenth time. All the bottom end is together and torqued. I'm

getting ready to bolt the heads on. I already checked valve to piston

clearance and wrote the figures down, but the Voices told me to check it

again. More bad news - the exhaust valve doesn't even touch the clay, but I

whacked an intake valve into the piston hard. WTF?

Okay, the crank is back in, bearing clearances are fine, everything is round

or straight as it's supposed to be, and the block has been washed and dried

for the dozenth time. All the bottom end is together and torqued. I'm

getting ready to bolt the heads on. I already checked valve to piston

clearance and wrote the figures down, but the Voices told me to check it

again. More bad news - the exhaust valve doesn't even touch the clay, but I

whacked an intake valve into the piston hard. WTF?

Back when I was trial fitting the engine pieces I had degreed the cam. It

wound up 20 degrees advanced. I checked it half a dozen times, then checked a

known-good cam just in case I was making some stupid mistake over and over.

Nope, it's 20 degrees off. I finally called Iskenderian, who told me to just

send it back. They replaced it without comment. I should have realized that

being off that far would do dramatic things to the valve to piston clearances,

but noooo... after degreeing the new cam it was apparent the pistons would

need to be cut again.

You can't really see it well in this shot, but #3 piston is covered with felt

tip markings showing where the new valve relief needs to be cut.

You can't really see it well in this shot, but #3 piston is covered with felt

tip markings showing where the new valve relief needs to be cut.

The lifter valley is painted with Nybco white epoxy paint. I can't find any

local place that still sells it. The VHT white turns sort of yellowy when it

gets oil on it, while the Nybco stuff always stayed bright white.

There's no real reason the lifter valley has to be painted; I just

think it looks nice.

Here we are on the mill fixture again. I pulled the pistons one at a time,

cut them, cleaned them, reassembled the ring packs and bearings, and

reinstalled them before going to the next piston. It took a lot of

cutting to clear the intake valves. These pistons also have offset piston

pins, so the left and right banks had slightly different setups since the

fixture locates the pistons by the pins.

Here we are on the mill fixture again. I pulled the pistons one at a time,

cut them, cleaned them, reassembled the ring packs and bearings, and

reinstalled them before going to the next piston. It took a lot of

cutting to clear the intake valves. These pistons also have offset piston

pins, so the left and right banks had slightly different setups since the

fixture locates the pistons by the pins.

Okay, valve/piston clearance is okay, everything is double-checked now,

wrapping up the bottom end. This engine uses an MPG Head Service windage

tray, which is also sold by Ford Motorsport. It's a pretty nice piece. The

lump of clay on the oil pickup is for checking the pickup-to-pan clearance.

I had to bend it slightly to clear the Milodon oil pan.

Okay, valve/piston clearance is okay, everything is double-checked now,

wrapping up the bottom end. This engine uses an MPG Head Service windage

tray, which is also sold by Ford Motorsport. It's a pretty nice piece. The

lump of clay on the oil pickup is for checking the pickup-to-pan clearance.

I had to bend it slightly to clear the Milodon oil pan.

NOW it's time to put the heads on for the last time. The Motorsport oil

pump driveshaft didn't have a retaining clip and could fall down into the oil

pan when you pulled the distributor. I made an aluminum collar for it on the

lathe and pressed it on. The distributor was in there to line it up so I

could rotate the engine and make sure the crank didn't hit it.

NOW it's time to put the heads on for the last time. The Motorsport oil

pump driveshaft didn't have a retaining clip and could fall down into the oil

pan when you pulled the distributor. I made an aluminum collar for it on the

lathe and pressed it on. The distributor was in there to line it up so I

could rotate the engine and make sure the crank didn't hit it.

Fortunately I hadn't bent any valves checking the clearances. All cylinders

passed the vacuum tester check.

The mirror finish on the cylinder walls takes a while to generate with the

hone. That's what Speed-Pro calls out in their instructions, though. Cross

hatching the cylinders went away with chrome rings; moly rings want a smooth

surface.

The engine used standard-length Motorsport hardened pushrods, believe it or

not! It's rather rare for a Ford to have the pushrod length anywhere close

when you're running roller rockers, since most rollers are really Chevy parts,

and the cup height is different.

The engine used standard-length Motorsport hardened pushrods, believe it or

not! It's rather rare for a Ford to have the pushrod length anywhere close

when you're running roller rockers, since most rollers are really Chevy parts,

and the cup height is different.

I'm setting the valve lash with a dial indicator. Some people like to play

spin-the-pushrod and count turns on the lock nut, but the dial indicator is

more accurate when you're using poly-locks, which tend to change their height

when the lock nut takes up the slack in the threads.

Dave sent a brand new timing cover for the engine. I installed it and the

rebuilt Damper Dudes damper. My TDC piston stop tool wouldn't work with the

Edelbrock heads, so I had to make a new one. Good thing I did; see the step

in the tape? That's how far the timing marks were off. Not too unusual for a

small Ford since Ford has used a bunch of different locations for the marks

and pointers. I used my Dremel to mark true TDC and 8 before.

Dave sent a brand new timing cover for the engine. I installed it and the

rebuilt Damper Dudes damper. My TDC piston stop tool wouldn't work with the

Edelbrock heads, so I had to make a new one. Good thing I did; see the step

in the tape? That's how far the timing marks were off. Not too unusual for a

small Ford since Ford has used a bunch of different locations for the marks

and pointers. I used my Dremel to mark true TDC and 8 before.

The Far-East timing cover fit okay... but the four oil pan bolt holes on the

bottom were metric! I had actually dug out four compatible-pitch metric bolts

from my bench stock when I realized it would be a really nasty thing to do to

someone; the holes were close enough to cross-thread a 1/4-20 oil pan bolt in

to, either breaking off the bolt or stripping the hole. Just the ticket when

you're laying on the ground trying to put the oil pan back on. I retapped the

holes to 1/4-20. Now it doesn't have four weird pan bolts. Details,

details...

============================================================================

MAXIMUM OVERDRIVE RACING ENGINES

379 Ford stroker

completed 01/20/01

warranty: If it breaks, you get to keep all the pieces you can find.

*****

351 Ford stroked to 3.66", .030 overbore (379 CID)

Isky 280 Mega cam, 232/232 @ .050, .517/.517 lift, 108 lobe center

Edelbrock Performer RPM aluminum heads

Compression:

776 cc swept volume (bore/stroke 4.060/3.66)

60 cc nominal chamber volume

- 2 cc +.010" deck

7.3 cc .035 gasket

5 cc valve notches (estimated)

--------

7-.3 cc total clearance volume

776/70.3 = 11.0:1 CR

*****

===========================================================================

* 3 oil filters, application: 1978 Nissan 510, 2.0L 4 cyl (L20B)

Purolator Filter number L30119

Fram PH2850

Motorcraft FL-181

Wix 51452

These are full size, have no bypass spring, but do have the rubber

flapper for anti-drainback for faster oil pressure buildup on cold start.

This is technically a metric filter, but they will screw on just fine.

You might want to keep everything clean so you can take one back if they

have made a production change that keeps them from working.

*Check* for the rubber flapper and no spring, just in case the filter

maker has made a change. You can do without the flapper, but you don't

want the spring.

If you need a half height filter use the Purolator L22167 or equivalent.

* 15 quarts of non-synthetic oil, 10w30 or 10w40

* torque wrench good to 100 ft-lb minimum

* antiseize (high temp preferred)

* gasket sealer (Ultra Copper or Ultra Blue) (make sure whatever you use is

oil resistant - some silicone sealers are not! - read the label!)

* new crankshaft pilot bearing

* harmonic balancer bolt

* 1 bottle of one of the following oil additives:

Crane, Crower, Isky, Sig Erson, or other cam lube

GM Engine Oil Supplement

Chrysler High-Performance Supplement

Ford Oil Conditioner C2AZ-19579-A

* new spark plugs

COMPONENTS ---------------------------------------------------------------

crankshaft:

351W, 7M casting

stroked to 3.66"

mains 351W -.030" undersize

main bearing clearance .0015"

rods 2.123" small block Mopar (.001-.002" undersize)

polished journals

balanced (drill only)

Seal Saver on rear seal surface

pistons:

TRW L2256F-60 forged 1.55 pin height (for 350 Chevy)

flat top with four valve reliefs

4.060 diameter

pistons are actually Speed Pro with TRW part numbers

wristpin offsets .050" to quiet side

pistons flycut for Edelbrock heads and Isky cam

minimum .100" valve/piston clearance

rings:

standard small block Chevy. 4.060, Hastings, moly top

side clearance .003 top and second

ring gaps #1 .023 #5 .023 top

.023 .026 2nd

#2 .020 #6 .023

.022 .026

#3 .020 #7 .023

.021 .025

#4 .023 #8 .023

.024 .026

all oils ~.036

rods:

small block Mopar, 6.123" long

forgings checked for straightness and twist

narrowed small ends (1.00")

narrowed big ends

pin ends bushed down to .925 (.002 press for .927 pins)

steel bushings, .005" interference + tack weld

rod side clearances .010"

resized big ends (minimum size)

chamfered sides of big ends

Michigan 77 rod bearings, 340 Mopar

bearings narrowed to .770-.775" wide (stock .830")

rods use .001" and .002" shells for .002" rod oil clearance

.001" shells on top, .002" shells on bottom

some tangs filed to position bearings properly

note: Mopar tang notches are randomly positioned

block:

351W D4AE-6015-AA8 block casting, has bosses for four bolt mains

bored .060

honed to .005 piston/wall clearance, spec for TRW forging

honed to #600 finish (ultra smooth)

2 piece rear main seal (blue silicone around edges)

new core plugs (blue silicone sealer)

painted (Rust-Oleum black)

new cam bearings (King)

align honed mains

heads:

Edelbrock Performer 351W

5/16" guide plates

7/16" screw-in studs and polylocks

all ports passed vacuum check

heads take either taper or gasketed 14mm spark plugs, 5/8" reach

1/2" ARP head studs

cam:

Isky 280 Mega hydraulic

advertised figures (checked at .007" after opening to .010" before

closing)

intake exhaust

duration 280 280

open 32 BTDC 68 BBDC

close 68 ABDC 32 ATDC

lobe lift .323 .323

valve lift .517 .517 (at 1.6:1)

lash n/a n/a

lobe center 108

overlap 64

.050" figures

232 232

open 8 BTDC 44 BBDC

close 44 ABDC 8 ATDC

Isky cam lube used for assembly lube

firing order: 351W firing order

pushrods:

Ford Motorsport standard 351W (length checked) (customer provided)

rockers:

Crane 1.6" gold aluminum roller rockers, 7/16" (customer provided)

valves set to .030" preload with dial indicator during assembly

timing set:

Cloyes dual roller (customer provided)

cam chain index +4 (degreed in 4 degrees advanced)

289-type one piece fuel pump eccentric

oil slinger on snout of crank

oiling:

Melling high volume oil pump

Milodon pickup

Milodon oil pan

Motorsport billet driveshaft - made aluminum collar to retain

MPG windage tray, ~1/8" clearance to rotating assembly

harmonic balancer:

stock 351W, rebuilt by Damper Dudes (customer provided)

checked TDC, cut long TDC mark and short 10 before mark

flywheel:

Hays billet steel, balanced to 28oz

14 1/2" x 1/2" lightening holes required for rebalance

Ford Motorsport threadlocker-coated bolts

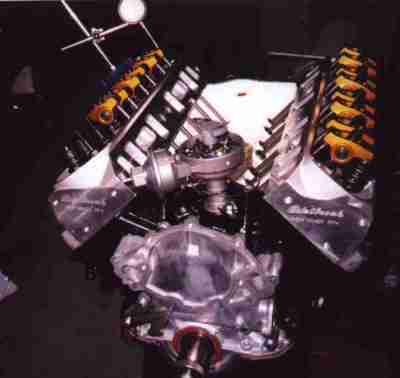

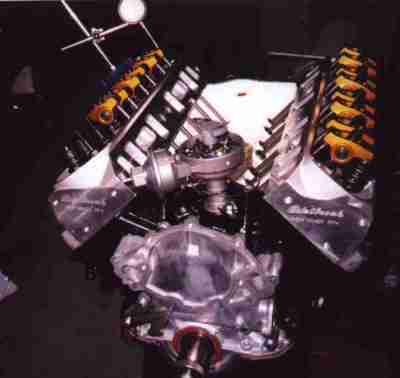

intake:

Edelbrock Performer RPM (customer provided)

===========================================================================

assembly lubricants:

rod bearings: 30wt ND

rings: Unilube two stroke oil

cylinder walls: Mobil 1 5w30

piston skirts: Mobil 1 5w30

wrist pins: Mobil 1 5w30

head bolts - threads: ARP moly grease

main bolts - threads: 30wt ND

head, main bolts - under head: ARP moly grease

rod bolts: ARP moly grease

cam bolt: Fel-Pro Grey Bolt Prep

cam retainer plate bolts: Loctite 252 blue

cam lobes: Crane cam lube

cam journals: Isky cam lube

cam distributor drive gear: Isky cam lube

cam retainer plate/sprocket: moly grease

crankshaft rear oil seal: Mobil 1 5w30

===========================================================================

Stewart-Warner Model 2000 Industrial Balancer

balance:

(reciprocating)

621 piston

143 pin

226 pin end of rod

59 rings

(rotating)

497 rod big end

497 rod big end

49 rod bearing (.770-.775 wide)

49 rod bearing (.770-.775 wide)

---

2141 grams bob weight

critical speed 750 RPM

resonant speed 625 RPM

max front imbalance .015 oz/in

max rear imbalance .02 oz/in

(balance is 1/10 of standard spec; close to the machine's resolution limit)

balance was drill-only

balanced for 28oz damper and flywheel

===========================================================================

RUN-IN: -----------------------------------------------------------------

Make sure you don't have any loose wires or hoses in the way of the fan

before firing the engine. It is a great temptation to just start it up

with nonessentials hanging hither and yon.

Pour in 5 quarts of your favorite brand of non-synthetic oil, 10-30 or 10-40

weight, one bottle of General Motors Engine Oil Supplement, and screw

on an oil filter. It probably wouldn't hurt to fill the filter before

putting it on.

With the "+"coil wire disconnected and spark plugs out, crank the engine over

until oil comes out the pushrods, or use an engine priming tool and a drill.

Attach the coil wire and valve covers, put the plugs in, attach plug wires.

Fill the radiator with straight water.

Start the motor and run it up to 2000 RPM for 20 minutes to break in the cam.

DO NOT IDLE. If you don't have a tach handy, run it up to a fast idle, then

guess at twice as fast. Wedge a piece of cardboard or folded paper between

the idle stop screw and throttle linkage.

Use the timing light to set the timing to 8 degrees at idle; it's okay to let

the engine to drop to idle for a few moments to do this.

Smoke and noise will come from the motor as paint burns off, etc. Ignore

anything that doesn't sound terminal. Water temp will probably go right on

up there; it's okay as long as it doesn't go over 230 or boil over. If you

have near neighbors remember this will make a fair amount of noise.

Shut down. Change oil, filter, drain radiator and fill with 50/50 antifreeze

or other coolant. Take care of any leaks or problems. Let engine cool.

Break in by driving around for about a hundred miles. Try not to idle in

traffic. Change oil and filter again. Check for leaks. The engine is

ready to drive. At 3K miles you can change to synthetic oil if you wish.

Oil Viscosity:

Use the lowest viscosity oil required to maintain hot idle oil pressure of

at least 25 psi. This will circulate the maximum amount of oil through the

bearings. Very thick oil just goes right through the popoff valve built

into the oil pump and you can be starving the bearings while the guage

happily reads 60-80 PSI.

TORQUE SPECIFICATIONS -----------------------------------------------------

--------torque---------------spec-----------thread---lube------------------

rod bolts

stretch to .0065 (ARP spec .0062-.0067) 3/8-24 ARP moly lube

main cap bolts

torqued to 100 ft-lb (Ford spec 95-105) 1/2-13 oil

note: 1) use moly grease under bolt head

2) step 1: 50 ft-lb

step 2: 80 ft-lb (reverse pattern)

step 3: 100 ft-lb (reverse pattern)

head bolts

torqued to 70 ft-lb (ARP spec 65-72) 1/2-20 ARP moly lube

note: 1) with hardened washers, ARP moly lube both sides of washer

2) block is blind tapped, no sealer needed

3) step 1: 50 ft-lb

step 2: 70 ft-lb (reverse pattern)

step 2: 85 ft-lb (reverse pattern)

damper (harmonic balancer) bolt

(Ford spec 70-90) 5/8-18 oil

note: use automatic transmission fluid as lubricant when pressing damper on

intake manifold bolts

(Ford spec 23-25) 5/16-18 sealer

note: 1) see drawing for pattern

exhaust manifold bolts

(Ford spec 18-24) 5/16-18 antiseize

note: 1) see drawing for pattern

rocker studs (torque 40 ft-lb) 7/16-16 sealer

note: use high temp antiseize if available

timing chain sprocket bolt

torqued to 40 ft-lb (Ford spec 40-45) 3/8-16 (Fel-Pro Grey Bolt Prep)

cam retainer plate

torqued to 10 ft-lb (Ford spec 9-12) 1/4-20 (Fel-Pro Grey Bolt Prep)

oil pan bolts

(Ford spec 7-9) 1/4-20 dry

(Ford spec 9-11) 5/16-18 dry

oil drain plug

(Ford spec 15-25) 1/2-20 oil

water pump bolts

(torque 12-18) 5/16-18 antiseize

timing cover bolts

(torque 12-18) 5/16-18 antisieze

1/4 NPT threaded oilway plugs 1/4, 3/8 NPT Teflon tape

oil pump pickup

(Ford spec 9-11) 5/16-18 Loctite 242

oil pump cover plate

(Ford spec 9-11) 1/4-20 Loctite 242

oil pump body

(torque 30-35) 3/8-16 Loctite 242

spark plugs

18mm antiseize

bottom pulley to damper

(Ford spec 35-50) oil

valve cover

(Ford spec 3-5) 1/4-20 oil

fuel pump to timing cover

(Ford spec 19-27) 3/8-16 antiseize

fan to water pump

(Ford spec 12-18) 5/16-24 antiseize

carburetor to intake

(Ford spec 12-15) 5/16-18 antiseize

SPECIAL PARTS ------------------------------------------------------------

specially made parts: 1018 steel rod bushings

aluminum collar for oil pump drive rod

modified parts: rods narrowed both ends

rod bearings narrowed

pistons flycut

harmonic balancer remarked to true TDC

neutral flywheel balanced to 28oz

Here's the core and assorted bits as they came from the core yard.

Here's the core and assorted bits as they came from the core yard. Left to right:

Left to right: A better view of the relative rod lengths. The Chrysler rod has more meat on

the big end and a beefier cap than the other two.

A better view of the relative rod lengths. The Chrysler rod has more meat on

the big end and a beefier cap than the other two.

Narrowing the big ends on the milling machine. The Chrysler rods are

considerably wider than the Ford crank journals.

Narrowing the big ends on the milling machine. The Chrysler rods are

considerably wider than the Ford crank journals.

I had done several engines with Chevy pistons and Chrysler rods before. The

Federal-Mogul master catalog had a listing for a bronze pin bushing that fit

almost perfectly - hone the pin end out a bit, drive the bushing in, then hone

the bushing to fit.

I had done several engines with Chevy pistons and Chrysler rods before. The

Federal-Mogul master catalog had a listing for a bronze pin bushing that fit

almost perfectly - hone the pin end out a bit, drive the bushing in, then hone

the bushing to fit.

The Chrysler rods are good parts, but somewhere along the line I got the idea

one of them was bent. I scouted every other shop within 75 miles and couldn't

find one with a rod checker, so I designed and built my own, accurate to

within .00025". Two fixtures were required. This first one makes sure the

hole is perpendicular to the sides of the big end.

The Chrysler rods are good parts, but somewhere along the line I got the idea

one of them was bent. I scouted every other shop within 75 miles and couldn't

find one with a rod checker, so I designed and built my own, accurate to

within .00025". Two fixtures were required. This first one makes sure the

hole is perpendicular to the sides of the big end.

Piston vise, flycutter, and piston. Federal-Mogul now ships Speed-Pro pistons

in TRW boxes. There's nothing wrong with Speed-Pro pistons... except the TRW

valve reliefs in 350 Chevy pistons will clear Ford valves and Speed-Pro

pistons won't.

Piston vise, flycutter, and piston. Federal-Mogul now ships Speed-Pro pistons

in TRW boxes. There's nothing wrong with Speed-Pro pistons... except the TRW

valve reliefs in 350 Chevy pistons will clear Ford valves and Speed-Pro

pistons won't.

We're on final assembly here. Well, it was supposed to be. With the main

caps torqued down the crank turned with great difficulty. The crank was

standard size on the mains; I had just ass-umed it was straight. It was bent

almost .005" TIR on the #2 main. Everything had to come back apart, the crank

had to be straightened and ground .010" undersize on the mains, and new

bearings purchased.

We're on final assembly here. Well, it was supposed to be. With the main

caps torqued down the crank turned with great difficulty. The crank was

standard size on the mains; I had just ass-umed it was straight. It was bent

almost .005" TIR on the #2 main. Everything had to come back apart, the crank

had to be straightened and ground .010" undersize on the mains, and new

bearings purchased.

I put the newly turned crank in the block on its new bearings, snugged the

main caps down, and... it wouldn't turn! WTF? The Plastigage and micrometer

relayed the awful truth. This block, the third block, the one that was

Magnafluxed, torque plate honed, and detailed to the nines... this block had

the wrong main caps! Not only did they not make a round bore, they didn't fit

tightly in their cutouts. Damn!

I put the newly turned crank in the block on its new bearings, snugged the

main caps down, and... it wouldn't turn! WTF? The Plastigage and micrometer

relayed the awful truth. This block, the third block, the one that was

Magnafluxed, torque plate honed, and detailed to the nines... this block had

the wrong main caps! Not only did they not make a round bore, they didn't fit

tightly in their cutouts. Damn!

Okay, the crank is back in, bearing clearances are fine, everything is round

or straight as it's supposed to be, and the block has been washed and dried

for the dozenth time. All the bottom end is together and torqued. I'm

getting ready to bolt the heads on. I already checked valve to piston

clearance and wrote the figures down, but the Voices told me to check it

again. More bad news - the exhaust valve doesn't even touch the clay, but I

whacked an intake valve into the piston hard. WTF?

Okay, the crank is back in, bearing clearances are fine, everything is round

or straight as it's supposed to be, and the block has been washed and dried

for the dozenth time. All the bottom end is together and torqued. I'm

getting ready to bolt the heads on. I already checked valve to piston

clearance and wrote the figures down, but the Voices told me to check it

again. More bad news - the exhaust valve doesn't even touch the clay, but I

whacked an intake valve into the piston hard. WTF?

You can't really see it well in this shot, but #3 piston is covered with felt

tip markings showing where the new valve relief needs to be cut.

You can't really see it well in this shot, but #3 piston is covered with felt

tip markings showing where the new valve relief needs to be cut.

Here we are on the mill fixture again. I pulled the pistons one at a time,

cut them, cleaned them, reassembled the ring packs and bearings, and

reinstalled them before going to the next piston. It took a lot of

cutting to clear the intake valves. These pistons also have offset piston

pins, so the left and right banks had slightly different setups since the

fixture locates the pistons by the pins.

Here we are on the mill fixture again. I pulled the pistons one at a time,

cut them, cleaned them, reassembled the ring packs and bearings, and

reinstalled them before going to the next piston. It took a lot of

cutting to clear the intake valves. These pistons also have offset piston

pins, so the left and right banks had slightly different setups since the

fixture locates the pistons by the pins.

Okay, valve/piston clearance is okay, everything is double-checked now,

wrapping up the bottom end. This engine uses an MPG Head Service windage

tray, which is also sold by Ford Motorsport. It's a pretty nice piece. The

lump of clay on the oil pickup is for checking the pickup-to-pan clearance.

I had to bend it slightly to clear the Milodon oil pan.

Okay, valve/piston clearance is okay, everything is double-checked now,

wrapping up the bottom end. This engine uses an MPG Head Service windage

tray, which is also sold by Ford Motorsport. It's a pretty nice piece. The

lump of clay on the oil pickup is for checking the pickup-to-pan clearance.

I had to bend it slightly to clear the Milodon oil pan.

NOW it's time to put the heads on for the last time. The Motorsport oil

pump driveshaft didn't have a retaining clip and could fall down into the oil

pan when you pulled the distributor. I made an aluminum collar for it on the

lathe and pressed it on. The distributor was in there to line it up so I

could rotate the engine and make sure the crank didn't hit it.

NOW it's time to put the heads on for the last time. The Motorsport oil

pump driveshaft didn't have a retaining clip and could fall down into the oil

pan when you pulled the distributor. I made an aluminum collar for it on the

lathe and pressed it on. The distributor was in there to line it up so I

could rotate the engine and make sure the crank didn't hit it.

The engine used standard-length Motorsport hardened pushrods, believe it or

not! It's rather rare for a Ford to have the pushrod length anywhere close

when you're running roller rockers, since most rollers are really Chevy parts,

and the cup height is different.

The engine used standard-length Motorsport hardened pushrods, believe it or

not! It's rather rare for a Ford to have the pushrod length anywhere close

when you're running roller rockers, since most rollers are really Chevy parts,

and the cup height is different.

Dave sent a brand new timing cover for the engine. I installed it and the

rebuilt Damper Dudes damper. My TDC piston stop tool wouldn't work with the

Edelbrock heads, so I had to make a new one. Good thing I did; see the step

in the tape? That's how far the timing marks were off. Not too unusual for a

small Ford since Ford has used a bunch of different locations for the marks

and pointers. I used my Dremel to mark true TDC and 8 before.

Dave sent a brand new timing cover for the engine. I installed it and the

rebuilt Damper Dudes damper. My TDC piston stop tool wouldn't work with the

Edelbrock heads, so I had to make a new one. Good thing I did; see the step

in the tape? That's how far the timing marks were off. Not too unusual for a

small Ford since Ford has used a bunch of different locations for the marks

and pointers. I used my Dremel to mark true TDC and 8 before.