brought to you by: Dave Williams

This page: www.bacomatic.org/~dw/fordv8/boss429/boss429.htm

Main page: http://www.bacomatic.org/~dw/index.htm

Last Updated: 16 Jul 2003

Author: Dave Williams; dlwilliams=aristotle=net

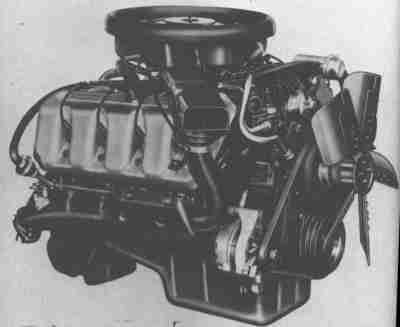

1970 BOSS 429.

1970 BOSS 429.

Before putting the BOSS 429 into the Mustang, Ford released it to selected

racers as a crate motor like they sold the 427 SOHC. This one is in Connie

Kalitta's Top Fuel dragster.

Before putting the BOSS 429 into the Mustang, Ford released it to selected

racers as a crate motor like they sold the 427 SOHC. This one is in Connie

Kalitta's Top Fuel dragster.

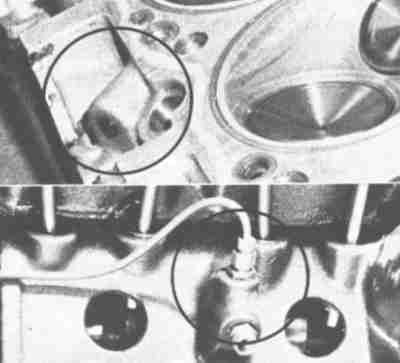

The intake rocker was very short and the exhaust rocker very long, the same

way the Chrysler Hemi or Ardun Fords were laid out. They were simple steel

forgings running on bronze bushings. Ford apparently felt that roller

bearings weren't necessary.

The intake rocker was very short and the exhaust rocker very long, the same

way the Chrysler Hemi or Ardun Fords were laid out. They were simple steel

forgings running on bronze bushings. Ford apparently felt that roller

bearings weren't necessary.

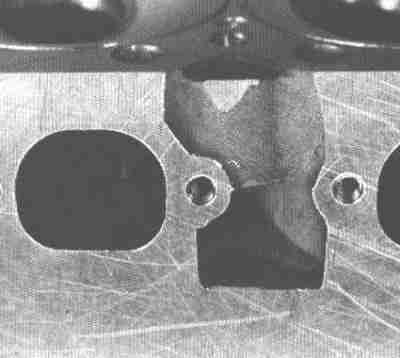

High exhaust ports are reminescent of later high-ported 351C designs.

Flattened floor improved flow at low lift.

High exhaust ports are reminescent of later high-ported 351C designs.

Flattened floor improved flow at low lift.

The BOSS 429 valves sit at compound angles just like a regular 429. Ford felt

shaft mounted rockers were more reliable for a racing engine, so the BOSS 429

got shaft mounted rockers. One shaft for every rocker! It took lots of

expensive machining in those pre-CNC days to do it.

The BOSS 429 valves sit at compound angles just like a regular 429. Ford felt

shaft mounted rockers were more reliable for a racing engine, so the BOSS 429

got shaft mounted rockers. One shaft for every rocker! It took lots of

expensive machining in those pre-CNC days to do it.

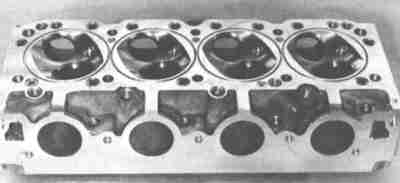

Intake and exhaust ports have nearly straight shots to the cylinders. Offset

was to promote swirl for more efficient combustion. This view of a T head

shows off the O-ring recesses.

Intake and exhaust ports have nearly straight shots to the cylinders. Offset

was to promote swirl for more efficient combustion. This view of a T head

shows off the O-ring recesses.

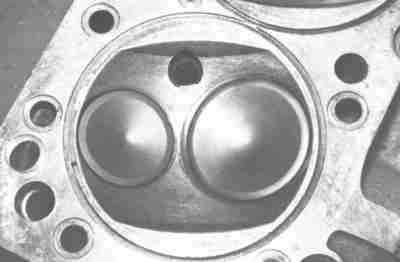

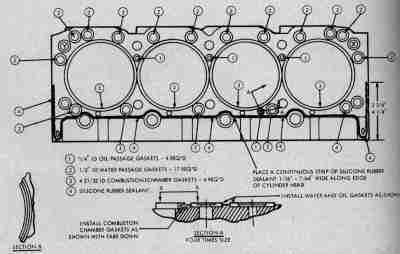

BOSS 429 T combustion chamber. The small quench ledges on each side are the

reason for the "semi-hemi" descriptor. The shallow counterbores around the

combustion chamber and various water holes are for O rings. Rubber O rings

seal water and oil; V-shaped Wills rings seal combustion pressure. No

conventional gasket was used.

BOSS 429 T combustion chamber. The small quench ledges on each side are the

reason for the "semi-hemi" descriptor. The shallow counterbores around the

combustion chamber and various water holes are for O rings. Rubber O rings

seal water and oil; V-shaped Wills rings seal combustion pressure. No

conventional gasket was used.

This is the T-series head sealing system. It uses rubber and metal crush

rings instead of a paper gasket. When the engine was torn down, the heads

came right off and the repaired engine could be reassembled at the track

without time-consuming scraping and cleaning of the gasket surfaces.

This is the T-series head sealing system. It uses rubber and metal crush

rings instead of a paper gasket. When the engine was torn down, the heads

came right off and the repaired engine could be reassembled at the track

without time-consuming scraping and cleaning of the gasket surfaces.

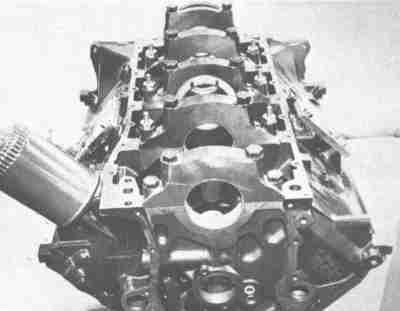

Regular production 429 and 460 blocks don't have the oil drillings for the

rocker shafts. To use BOSS 429 heads on these blocks you need to run separate

oil lines to the heads. The crossover block in the lifter valley is a

convenient place to pick up oil.

Regular production 429 and 460 blocks don't have the oil drillings for the

rocker shafts. To use BOSS 429 heads on these blocks you need to run separate

oil lines to the heads. The crossover block in the lifter valley is a

convenient place to pick up oil.

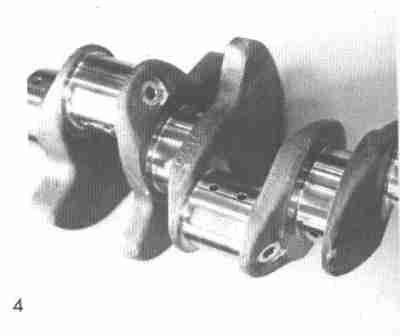

Four bolt mains on the BOSS 429 block. Other than the screw-in core plugs,

it's not much different from the four bolt Cobra Jet block.

Four bolt mains on the BOSS 429 block. Other than the screw-in core plugs,

it's not much different from the four bolt Cobra Jet block.

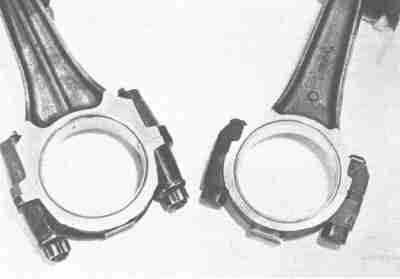

"T" rod on the left, with half inch rod bolts and pressure oiling to the

floating wristpin. "S" rod at right.

"T" rod on the left, with half inch rod bolts and pressure oiling to the

floating wristpin. "S" rod at right.

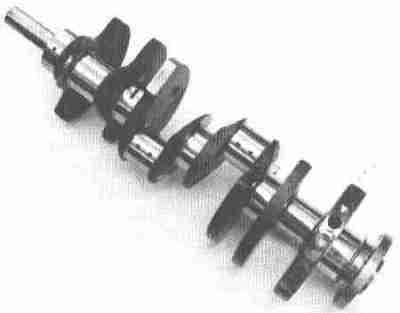

The BOSS 429 crank was forged steel as opposed to cast iron for all other

passenger car cranks. Some heavy truck engines also got a forged crank, but

I've never been able to make a direct comparison to see if they're the same

basic forging or not. The truck cranks have a larger diameter snout like the

FT variant of the FE.

The BOSS 429 crank was forged steel as opposed to cast iron for all other

passenger car cranks. Some heavy truck engines also got a forged crank, but

I've never been able to make a direct comparison to see if they're the same

basic forging or not. The truck cranks have a larger diameter snout like the

FT variant of the FE.

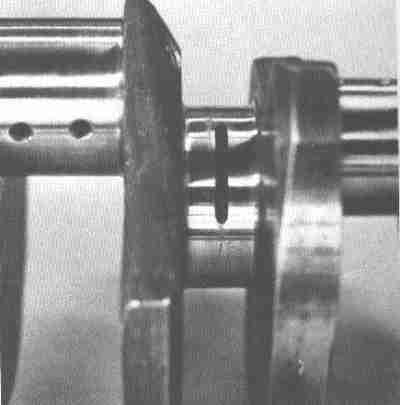

Oil lead-in groove was forged in, not ground. It was only done on the #2 and

#4 mains; #1, #3, and #5 had ordinary holes.

Oil lead-in groove was forged in, not ground. It was only done on the #2 and

#4 mains; #1, #3, and #5 had ordinary holes.

The crank featured a continuous oiling path from end to end, just like the

Indy 255 - any main bearing could feed all the rod bearings. The rod oil

holes are moved further down the sides to a more advantageous spot for feeding

oil. The rod throws have largish holes drilled through for lightness and to

act as "plenums" in the oil path. They also tended to centrifuge out any flak

in the oil and keep it from getting to the rod bearings.

The crank featured a continuous oiling path from end to end, just like the

Indy 255 - any main bearing could feed all the rod bearings. The rod oil

holes are moved further down the sides to a more advantageous spot for feeding

oil. The rod throws have largish holes drilled through for lightness and to

act as "plenums" in the oil path. They also tended to centrifuge out any flak

in the oil and keep it from getting to the rod bearings.