brought to you by: Dave Williams

This page: www.bacomatic.org/~dw/fordv8/cleve/cleve.htm

Main page:

http://www.bacomatic.org/~dw/index.htm

Last Updated: 18 Sep 2003

Author: Dave Williams; dlwilliams=aristotle=net

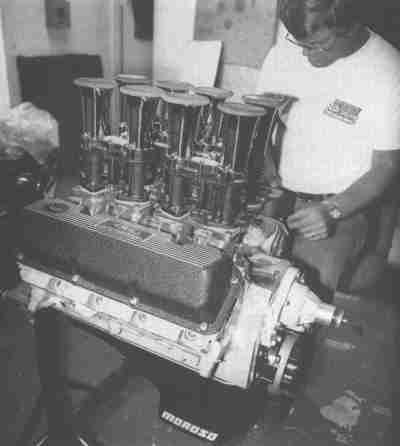

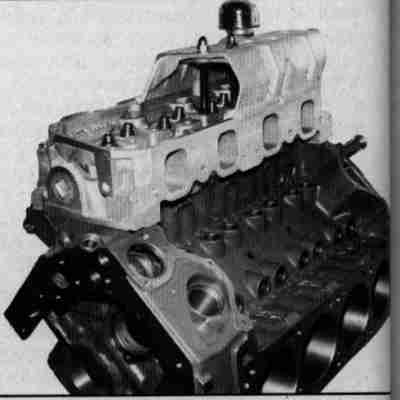

This is one of Mike Cook's Clevelands being prepped for installation in a

DeTomaso Pantera.

This is one of Mike Cook's Clevelands being prepped for installation in a

DeTomaso Pantera.

Ak Miller racing BOSS 351 blueprint specifications

(from Peterson's Complete Book Of Engines #8, 1972)

Main Bearings ........................... Select fit for .0025-.0030-in.

Crankshaft End-Play ..................... .004-.010-in.

Connecting Rod Bearings ................. Select fit for .0025-.0030-in.

Connecting Rod End-Play (two rods) ...... .018-.022-in.

Piston to Bore .......................... .0065-.0075-in.

Piston to Pin ........................... .006-.008-in.

Piston Pin to Connecting Rod ............ .0006-.0012-in. interference

(pressed pin - minimum 1800

pounds force to move pin)

Valve Stem to Guide, exhaust ............ .0011-.0022-in.

Valve Stem to Guide, intake ............. .0007-.0018-in.

Camshaft Bearing ........................ .001-.006-in.

Camshaft End-Play ....................... .001-.006-in.

Flywheel Hub Face Runout ................ .002-in.

Damper to Crankshaft .................... .000-.002-in interference

Valve Stem Seal to Valve Stem ........... none

(intake and exhaust)

Valve Lash, Intake and Exhaust .......... .026-.028-in. cold (.025-in. hot)

Piston Ring to Groove ................... Compression ring .002-.005-in.

Oil ring snug

Distributor Gear Backlash ............... .007-.017-in.

Distributor Shaft End-Play .............. .004-.025-in.

Piston Ring Gap in Bore ................. .015-.020-in. Compression rings

.015-.069-in. Oil ring

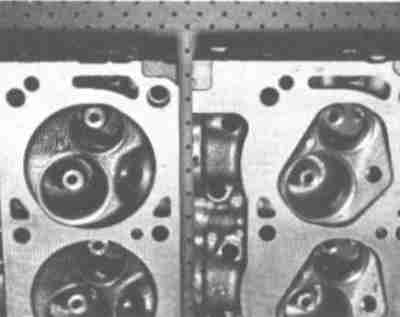

Open and closed chamber heads. All American-market 2V heads were open

chamber. Some Australian 2V heads were closed chamber; many of these have

been imported to the States. Most 4V heads were open chamber, but some were

closed chamber. All BOSS 302 and BOSS 351 heads were closed chamber.

Open and closed chamber heads. All American-market 2V heads were open

chamber. Some Australian 2V heads were closed chamber; many of these have

been imported to the States. Most 4V heads were open chamber, but some were

closed chamber. All BOSS 302 and BOSS 351 heads were closed chamber.

Closed chamber heads make more power than open chamber heads. They raise the

CR, which is usually a good thing, have higher turbulence due to the quench

area, and the smaller chamber makes for a shorter flame path. The open

chamber heads are low on NOx emissions, which is why they are the main type.

All 351M and 400 heads were open chamber.

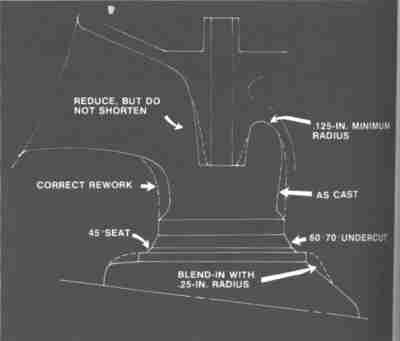

Here's how Ford's Muscle Parts division recommended you port your BOSS 302 or

351 Cleveland 4V heads. You don't need to make them any bigger, just take

care of some detail work.

Here's how Ford's Muscle Parts division recommended you port your BOSS 302 or

351 Cleveland 4V heads. You don't need to make them any bigger, just take

care of some detail work.

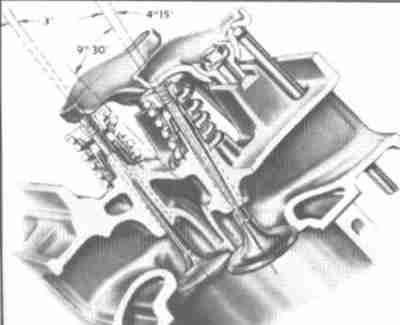

How the Cleveland's valves are canted.

How the Cleveland's valves are canted.

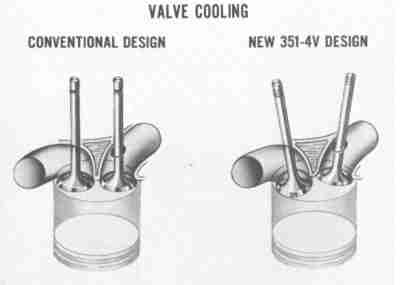

Cleveland vs. Windsor valve cooling. Probably just smoke and mirrors from

Ford's marketing department.

Cleveland vs. Windsor valve cooling. Probably just smoke and mirrors from

Ford's marketing department.

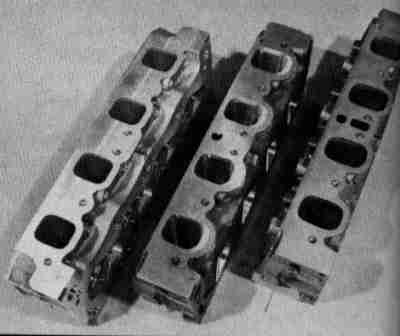

From right to left, a standard 4V head, an early '80s NASCAR 4V head with the

ports partially filled with epoxy, and one of the very first A3 aluminum

heads. Ford's aluminum racing heads diverged rapidly from the basic canted-

valve Cleveland design after that.

From right to left, a standard 4V head, an early '80s NASCAR 4V head with the

ports partially filled with epoxy, and one of the very first A3 aluminum

heads. Ford's aluminum racing heads diverged rapidly from the basic canted-

valve Cleveland design after that.

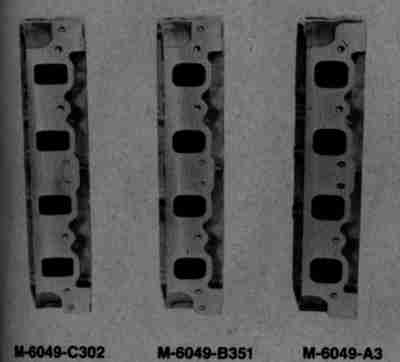

The M-6049-A3 heads were fairly straightforward aluminum copies of the high-

ported iron 4V heads used in oval track racing. The M-6049-B351 heads were

similar, but with smaller ports. It looks like they just made the whole port

smaller instead of filling in the bottoms to raise the overall port.

The M-6049-A3 heads were fairly straightforward aluminum copies of the high-

ported iron 4V heads used in oval track racing. The M-6049-B351 heads were

similar, but with smaller ports. It looks like they just made the whole port

smaller instead of filling in the bottoms to raise the overall port.

The M-6049-C302 was marketed as a variant of the A3, "optimized for engines

under 320 CID", but it's a wholly different head, with rectangular intake

ports and round exhaust ports. The C302 was the beginning of the move from

the Cleveland design to the hybrid Windsor heads that are in current favor.

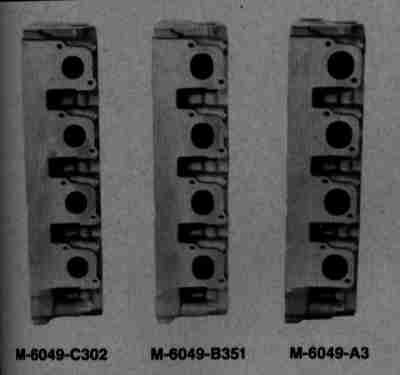

The exhaust ports of the above heads.

The exhaust ports of the above heads.

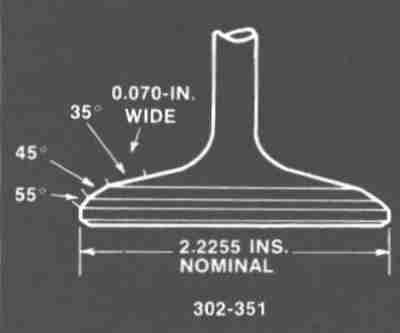

Here's how they recommended you rework the 351C valve for use with the port

work. The valve shape and seat geometry can make up as much as 50% of thr CFM

gained by a porting job.

Here's how they recommended you rework the 351C valve for use with the port

work. The valve shape and seat geometry can make up as much as 50% of thr CFM

gained by a porting job.

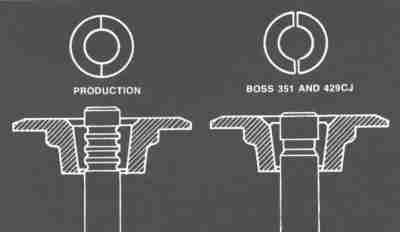

351 Cleveland rocker types. The "competition" pedestals are a trunnion with a

roller bearing on each side.

351 Cleveland rocker types. The "competition" pedestals are a trunnion with a

roller bearing on each side.

Another shot of the roller-pivot rockers. This idea went away for 25 years or

so, then returned via the aftermarket as a modification for 5.0 Windsor

rockers.

Another shot of the roller-pivot rockers. This idea went away for 25 years or

so, then returned via the aftermarket as a modification for 5.0 Windsor

rockers.

This shows the difference between the single and multiple groove valve

keepers. Unless you have a 1971 BOSS 351 or 1972 351 HO you have the multiple

groove keepers. The multigroove design lets the keepers butt against each

other, with enough clearance for the valve to rotate if it wants to. The

single groove design has a gap between the keepers and locks the valve firmly

to the retainer. The multigroove setup was supposed to let the valves rotate

and equalize temperature. It works fine in ordinary applications. It doesn't

work that well in high RPM uses because Ford used compressed Cheez-Wiz to

makes the keepers and they'll fail at high revs. That's not really a concern,

as the 30-year-old two-piece valves will have probably failed about the same

time anyway. Do not even attempt to use the original valves if you're doing a

performance rebuild. It's not even a good idea to re-use them for a stock

rebuild. Throw them away, bite the bullet, and buy new one-piece valves.

It's not cheap, but the alternative is having a head pop off where it's welded

to the stem, and I guarantee that will cost you more than a set of valves.

This shows the difference between the single and multiple groove valve

keepers. Unless you have a 1971 BOSS 351 or 1972 351 HO you have the multiple

groove keepers. The multigroove design lets the keepers butt against each

other, with enough clearance for the valve to rotate if it wants to. The

single groove design has a gap between the keepers and locks the valve firmly

to the retainer. The multigroove setup was supposed to let the valves rotate

and equalize temperature. It works fine in ordinary applications. It doesn't

work that well in high RPM uses because Ford used compressed Cheez-Wiz to

makes the keepers and they'll fail at high revs. That's not really a concern,

as the 30-year-old two-piece valves will have probably failed about the same

time anyway. Do not even attempt to use the original valves if you're doing a

performance rebuild. It's not even a good idea to re-use them for a stock

rebuild. Throw them away, bite the bullet, and buy new one-piece valves.

It's not cheap, but the alternative is having a head pop off where it's welded

to the stem, and I guarantee that will cost you more than a set of valves.

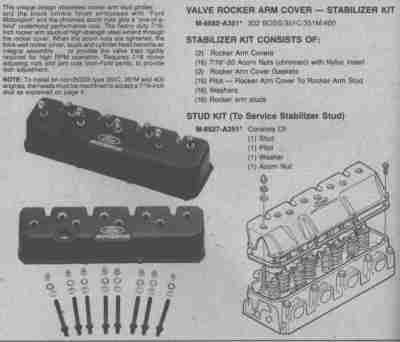

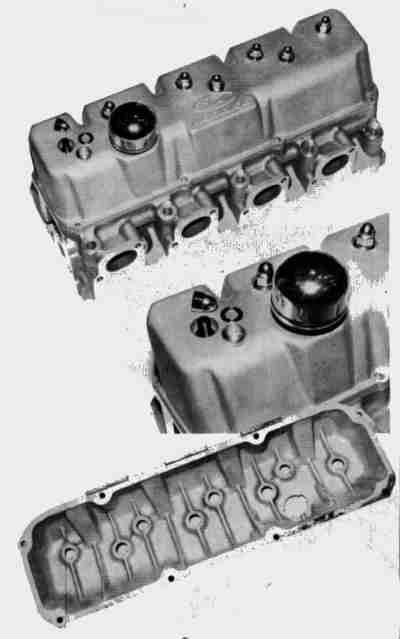

Back in the early '80s the Ford Motorsport catalog listed these way-cool valve

covers. Yes, they were a combination valve cover and stud girdle! Ford

didn't sell many, probably because prospective buyers figured they'd be more

hassle than they were worth, but the fangle factor is still very high...

Back in the early '80s the Ford Motorsport catalog listed these way-cool valve

covers. Yes, they were a combination valve cover and stud girdle! Ford

didn't sell many, probably because prospective buyers figured they'd be more

hassle than they were worth, but the fangle factor is still very high...

A cutaway shot of the stud-covers.

A cutaway shot of the stud-covers.

And one more picture... lousy image, but the only one I could find showing the

underside of the valve cover. There's only so much you can do with image

editing software.

And one more picture... lousy image, but the only one I could find showing the

underside of the valve cover. There's only so much you can do with image

editing software.

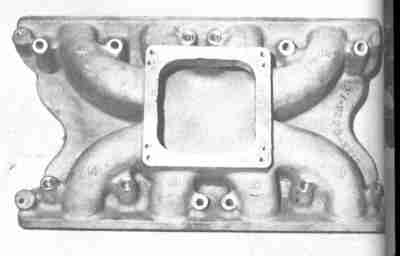

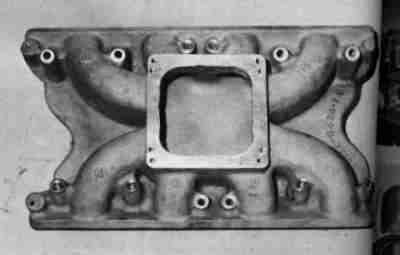

Ford Muscle Parts D1ZX-9425-FA intake manifold. This one was slightly

modified by Ak Miller by opening the four separate carb holes to one big hole

for added plenum volume.

Ford Muscle Parts D1ZX-9425-FA intake manifold. This one was slightly

modified by Ak Miller by opening the four separate carb holes to one big hole

for added plenum volume.

Ford Muscle Parts D1ZX-9425-FA single manifold. Ak Miller modified this one

by cutting out the webbing to turn four holes into one for more top-end flow.

Ford Muscle Parts D1ZX-9425-FA single manifold. Ak Miller modified this one

by cutting out the webbing to turn four holes into one for more top-end flow.

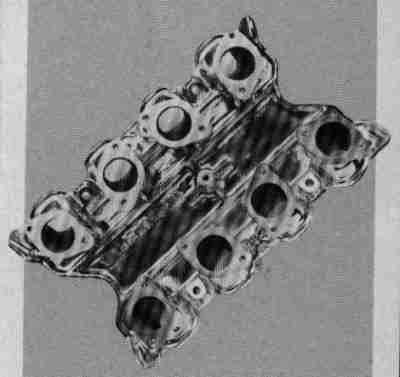

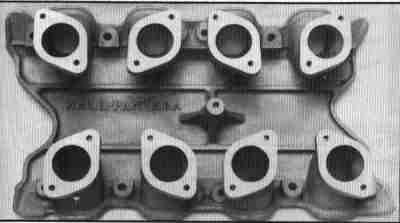

Hall Pantera had these Weber intakes cast up with their name on them. Note

how conveniently the Cleveland port spacing matches the Weber bore spacing.

Hall Pantera had these Weber intakes cast up with their name on them. Note

how conveniently the Cleveland port spacing matches the Weber bore spacing.

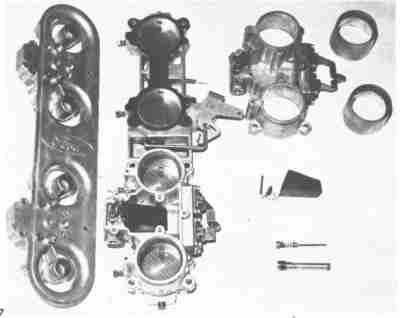

Inglese made these adapter plates to turn one row of carburetors around so the

butterflies mirrored each other on each bank instead of all turning the same

way. This cleaned up some fuel flow differences at low throttle settings.

Inglese made these adapter plates to turn one row of carburetors around so the

butterflies mirrored each other on each bank instead of all turning the same

way. This cleaned up some fuel flow differences at low throttle settings.

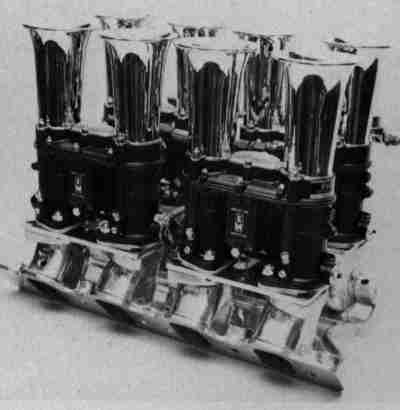

Assembled Weber setup with stacks. It's as tall as a tunnel ram. In a

Pantera that means a rear view mirror full of stacks. Few Pantera owners with

Webers seem to object, though...

Assembled Weber setup with stacks. It's as tall as a tunnel ram. In a

Pantera that means a rear view mirror full of stacks. Few Pantera owners with

Webers seem to object, though...

Hall Pantera intake from above. Boss is for mounting carb linkage.

Hall Pantera intake from above. Boss is for mounting carb linkage.

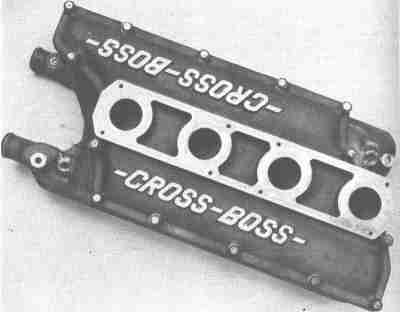

The famed Cross-BOSS intake for the BOSS 302 and Autolite inline four barrel

carburetor. This was designed for works Mustangs competing in SCCA Trans Am

races. Very few were made, but it was a dealer item.

The famed Cross-BOSS intake for the BOSS 302 and Autolite inline four barrel

carburetor. This was designed for works Mustangs competing in SCCA Trans Am

races. Very few were made, but it was a dealer item.

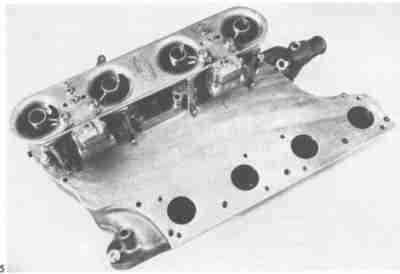

This Cross-BOSS intake has a fabricated cover plate to mount two Autolite

carburetors. Though two 1400 CFM carbs might sound like overkill, the effect

is very similar to an independent runner manifold such as four Webers. Two

1400s were about right for a high RPM 302 or mid-RPM 351; they couldn't feed

the drag racing 351s. Ford later developed a high rise manifold that looked

much like a tunnel ram. It incorporated small plenums beneath the carbs so

they could be shared among the cylinders.

This Cross-BOSS intake has a fabricated cover plate to mount two Autolite

carburetors. Though two 1400 CFM carbs might sound like overkill, the effect

is very similar to an independent runner manifold such as four Webers. Two

1400s were about right for a high RPM 302 or mid-RPM 351; they couldn't feed

the drag racing 351s. Ford later developed a high rise manifold that looked

much like a tunnel ram. It incorporated small plenums beneath the carbs so

they could be shared among the cylinders.

Autolite inline four barrels on true IR intake. That's supposed to be a

Cleveland intake, but it's apparently missing a valley cover and head adapter

piece.

Autolite inline four barrels on true IR intake. That's supposed to be a

Cleveland intake, but it's apparently missing a valley cover and head adapter

piece.

This is a highly-ported Offenhauser Dual Port. This shows a top view that

details the hogging out of the secondary dlenum into one large oval hole, and

it shows the section of the plenum top that was removed to allow porting for

the secondary plenum to deliver the same volume of air to the front two

cylinders as the remaining six. Image: Jim Sams

This is a highly-ported Offenhauser Dual Port. This shows a top view that

details the hogging out of the secondary dlenum into one large oval hole, and

it shows the section of the plenum top that was removed to allow porting for

the secondary plenum to deliver the same volume of air to the front two

cylinders as the remaining six. Image: Jim Sams

A view of the plenum note that the secondary plenum path for cylinders 4 & 5

are between the primary bore "tunnels". This area was ported quite a bit.

Image: Jim Sams

A view of the plenum note that the secondary plenum path for cylinders 4 & 5

are between the primary bore "tunnels". This area was ported quite a bit.

Image: Jim Sams

The divider milled back about 3/4" at the head flange. This is

said to increase the RPM limit to about 6K for this intake. Image: Jim Sams

The divider milled back about 3/4" at the head flange. This is

said to increase the RPM limit to about 6K for this intake. Image: Jim Sams

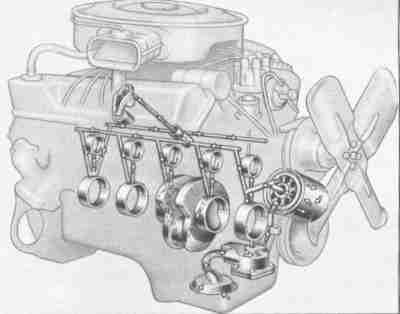

Here's the infamous Cleveland oiling system. Despite all the bullshit from

the ragazines it's a perfectly ordinary V8 oiling system - same as the 460,

same as Pontiac, Oldsmobile, and Cadillac V8s, and same as Chevrolet's 2.8 and

4.3 V6s.

Here's the infamous Cleveland oiling system. Despite all the bullshit from

the ragazines it's a perfectly ordinary V8 oiling system - same as the 460,

same as Pontiac, Oldsmobile, and Cadillac V8s, and same as Chevrolet's 2.8 and

4.3 V6s.

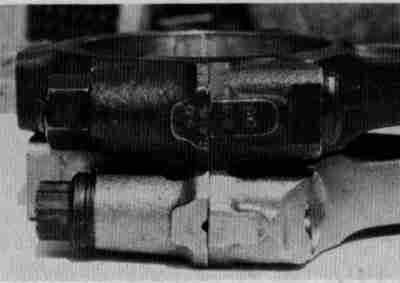

Installing oil restrictor plugs. The right one goes to the cam bearing, the

left to the left (driver's side) lifter gallery. The cam bearings are usually

restricted to .062-.068", the lefter gallery to .090-.125", depending on who

makes the plugs.

Installing oil restrictor plugs. The right one goes to the cam bearing, the

left to the left (driver's side) lifter gallery. The cam bearings are usually

restricted to .062-.068", the lefter gallery to .090-.125", depending on who

makes the plugs.

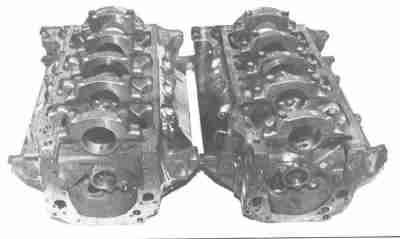

The 351 Cleveland was available in both two and four bolt versions. All the

blocks were the same; only the caps were different. You could retrofit four

bolt caps to any two bolt block simply by drilling and tapping the holes.

Ford never sold the caps separately, though, so you'd have to get them from a

dead four bolt block.

The 351 Cleveland was available in both two and four bolt versions. All the

blocks were the same; only the caps were different. You could retrofit four

bolt caps to any two bolt block simply by drilling and tapping the holes.

Ford never sold the caps separately, though, so you'd have to get them from a

dead four bolt block.

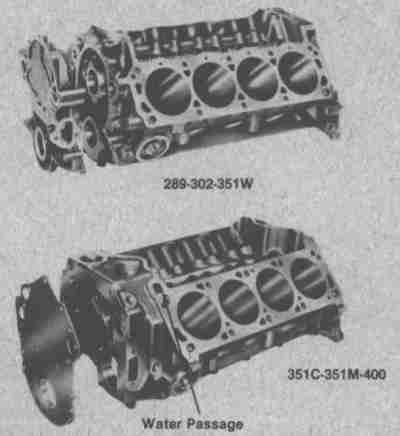

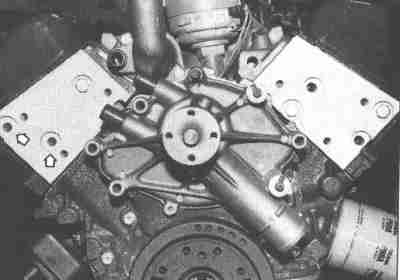

The Windsor series engines use a separate aluminum timing chain cover bolted

to the front of the block. The Cleveland extends the front of the block

forward and uses a sheet metal cover plate braced by the water pump. The

cast iron extension looks bulky, but it's a thin wall wasting. The Cleveland

is probably only about five pounds heavier there than the Windsor. In

exchange for this, there was one less gasket surface to leak. Windsors had a

habit of oozing coolant into the water pump bolt holes and eating on the

bolts, which would then break off when you tried to remove them. Eliminating

the aluminum cover also reduced problems with galvanic corrosion, which are no

big deal with modern coolants, but were an ongoing problem in the old days.

The first Windsors had aluminum water pumps; the reason they switched to iron

was to reduce corrosion-related warranty claims. They went back to aluminum

when corrosion inhibiting antifreeze became more common.

The Windsor series engines use a separate aluminum timing chain cover bolted

to the front of the block. The Cleveland extends the front of the block

forward and uses a sheet metal cover plate braced by the water pump. The

cast iron extension looks bulky, but it's a thin wall wasting. The Cleveland

is probably only about five pounds heavier there than the Windsor. In

exchange for this, there was one less gasket surface to leak. Windsors had a

habit of oozing coolant into the water pump bolt holes and eating on the

bolts, which would then break off when you tried to remove them. Eliminating

the aluminum cover also reduced problems with galvanic corrosion, which are no

big deal with modern coolants, but were an ongoing problem in the old days.

The first Windsors had aluminum water pumps; the reason they switched to iron

was to reduce corrosion-related warranty claims. They went back to aluminum

when corrosion inhibiting antifreeze became more common.

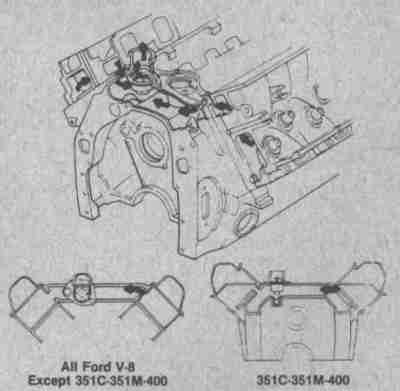

This is how the coolant flows in the 351 Cleveland. Instead of going from the

heads to the intake manifold like most engines, it goes back through the block

to the cast-iron snout. I don't know of any particular advantage behind this

setup, though the "dry" intake meant you didn't dump a bunch of coolant into

the oil when swapping intakes. I hardly think that was why Ford Engineering

did it, though.

This is how the coolant flows in the 351 Cleveland. Instead of going from the

heads to the intake manifold like most engines, it goes back through the block

to the cast-iron snout. I don't know of any particular advantage behind this

setup, though the "dry" intake meant you didn't dump a bunch of coolant into

the oil when swapping intakes. I hardly think that was why Ford Engineering

did it, though.

Ford Power Parts (FPP) sold these "Cleveland Capscrew" rods in the mid '80s.

The availability of better rod bolts and inexpensive aftermarket rods has made

this them obsolete, but they were trick in their day.

Ford Power Parts (FPP) sold these "Cleveland Capscrew" rods in the mid '80s.

The availability of better rod bolts and inexpensive aftermarket rods has made

this them obsolete, but they were trick in their day.

The capscrews were the same as used on the heavy duty 427 FE rods. FPP

doweled the Cleveland rods to keep the caps in alignment. This is the kind of

cool fangle you keep in mind for 'just in case', like when building stroker

engines.

The capscrews were the same as used on the heavy duty 427 FE rods. FPP

doweled the Cleveland rods to keep the caps in alignment. This is the kind of

cool fangle you keep in mind for 'just in case', like when building stroker

engines.

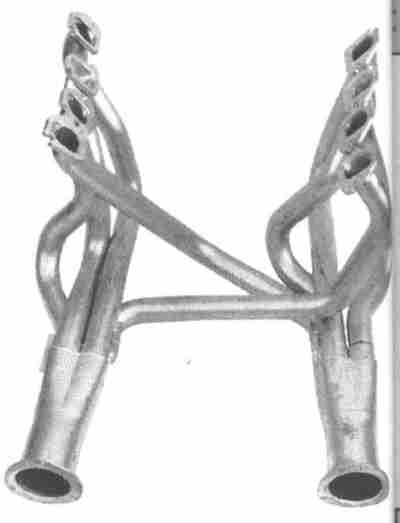

These headers from Tubular Automotive let you put a Cleveland in a '65-'66

Mustang. Tubular crossed two pipes under the pan to alleviate clearance

problems.

These headers from Tubular Automotive let you put a Cleveland in a '65-'66

Mustang. Tubular crossed two pipes under the pan to alleviate clearance

problems.

George Klass sells headers to put a Cleveland in Fox Mustangs.

As of 1975 this was the strongest engine Ford's engineers had built when

testing packages for Ford's drag racing program. The Autolite inline four

barrels had some problems carbureting during hard acceleration and kept the

setup from being successful in competition. Notice the small cast aluminum

plenums under the carburetors; even at 2 x 1400 CFM the Autolites were too

small for a high-winding Cleveland when being used on an independent-runner

intake; the plenums let the runners share venturis for more airflow.

As of 1975 this was the strongest engine Ford's engineers had built when

testing packages for Ford's drag racing program. The Autolite inline four

barrels had some problems carbureting during hard acceleration and kept the

setup from being successful in competition. Notice the small cast aluminum

plenums under the carburetors; even at 2 x 1400 CFM the Autolites were too

small for a high-winding Cleveland when being used on an independent-runner

intake; the plenums let the runners share venturis for more airflow.

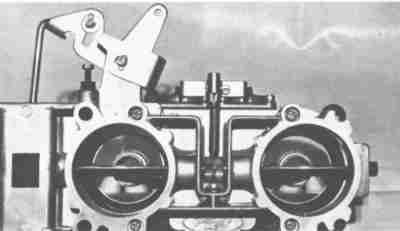

2.25" butterflies flowed 1400 CFM per carburetor. Each barrel had its own

metering jets and accelerator pump; essentially separate four one barrel

carburetors in a common body.

2.25" butterflies flowed 1400 CFM per carburetor. Each barrel had its own

metering jets and accelerator pump; essentially separate four one barrel

carburetors in a common body.

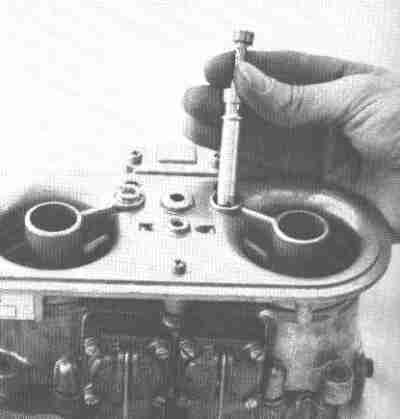

The Autolites used Weber-style emulsion tubes. Everything was accessible

without having to remove the carburetor from the manifold.

The Autolites used Weber-style emulsion tubes. Everything was accessible

without having to remove the carburetor from the manifold.

How many engines got their own carburetors designed for them? Ford sold these

special Autolite 1400 CFM inline four barrels and appropriate manifolding over

the counter to anyone who wanted them.

How many engines got their own carburetors designed for them? Ford sold these

special Autolite 1400 CFM inline four barrels and appropriate manifolding over

the counter to anyone who wanted them.

These adapter plates were available from Advanced Engineering West circa 1985.

They let you mount Fox Mustang serpentine accessories to a BOSS 302.

These adapter plates were available from Advanced Engineering West circa 1985.

They let you mount Fox Mustang serpentine accessories to a BOSS 302.