Miscellaneous Ford Stuff

brought to you by: Dave Williams

This page: www.bacomatic.org/~dw/fordv8/fordmisc/fordmisc.htm

Main page: http://www.bacomatic.org/~dw/index.htm

Last Updated: 16 Jul 2003

Author: Dave Williams; dlwilliams=aristotle=net

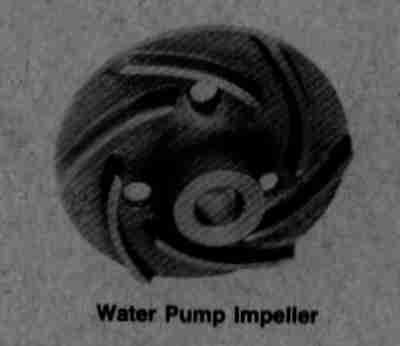

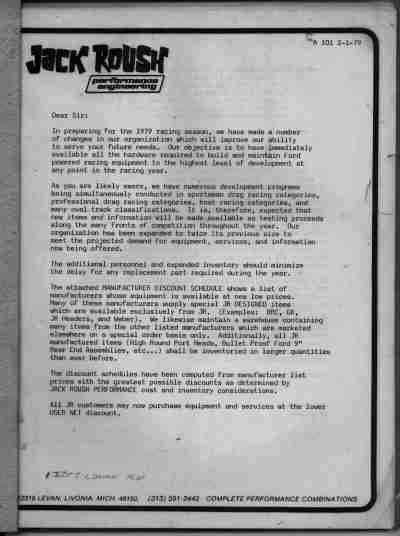

This is the cast iron, curved-vane water pump impeller the old Muscle Parts

catalog recommended for upgrading your racing BOSS 351. It's still in the

catalog as M-8512-A302. I tried to purchase one in 1995. The best price I

could find was around $50. Then I found out there are half a dozen different

housings with different internal shapes; the impeller was designed for the M-

8505-A331 aluminum housing ($150) and there are major differences among the

rest of the small block housings. It's easier just to buy a whole aftermarket

pump with a good impeller instead of a sheet metal paddle.

This is the cast iron, curved-vane water pump impeller the old Muscle Parts

catalog recommended for upgrading your racing BOSS 351. It's still in the

catalog as M-8512-A302. I tried to purchase one in 1995. The best price I

could find was around $50. Then I found out there are half a dozen different

housings with different internal shapes; the impeller was designed for the M-

8505-A331 aluminum housing ($150) and there are major differences among the

rest of the small block housings. It's easier just to buy a whole aftermarket

pump with a good impeller instead of a sheet metal paddle.

Early rodders often ran dual-fuel setups. This Ford coupe has a 5-gallon

aluminum tank with high-octane racing fuel. Hand-operated plunger pump

pressurizes tank to 6 PSI to ensure positive pressure to get fuel to the main

fuel pump.

Early rodders often ran dual-fuel setups. This Ford coupe has a 5-gallon

aluminum tank with high-octane racing fuel. Hand-operated plunger pump

pressurizes tank to 6 PSI to ensure positive pressure to get fuel to the main

fuel pump.

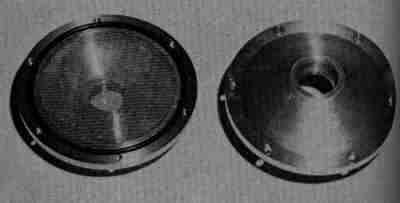

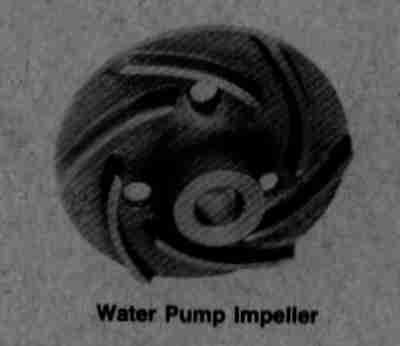

Okay, not a Ford-specific part. This Eelco cleanable oil filter was available

in 1961. It, or copies of it, have been available under half a dozen names

since. I still think that screen is some kind of commonly-available part you

could probably find in a hydraulic shop.

Okay, not a Ford-specific part. This Eelco cleanable oil filter was available

in 1961. It, or copies of it, have been available under half a dozen names

since. I still think that screen is some kind of commonly-available part you

could probably find in a hydraulic shop.

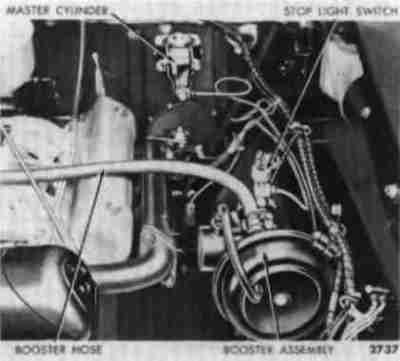

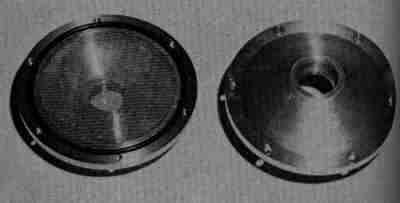

Ford used this remote-mount power brake booster setup in 1957-1959 models.

Many of the remote-booster street rod conversions use these parts.

Ford used this remote-mount power brake booster setup in 1957-1959 models.

Many of the remote-booster street rod conversions use these parts.

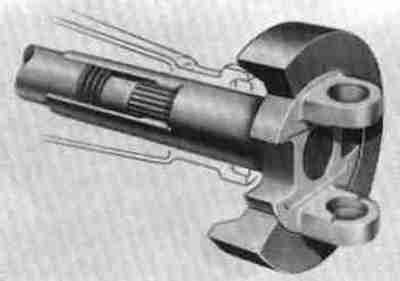

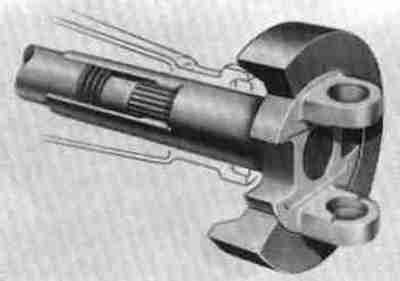

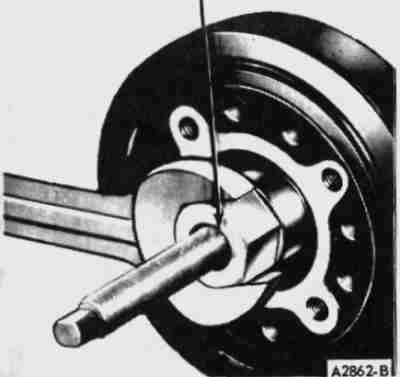

Ford added this harmonic-balancer-style vibration damper to the front yoke of

some models beginning in 1967. The damper was just another step in

controlling what Ford calls "NVH", for "Noise, Vibration, and Harshness."

Ford added this harmonic-balancer-style vibration damper to the front yoke of

some models beginning in 1967. The damper was just another step in

controlling what Ford calls "NVH", for "Noise, Vibration, and Harshness."

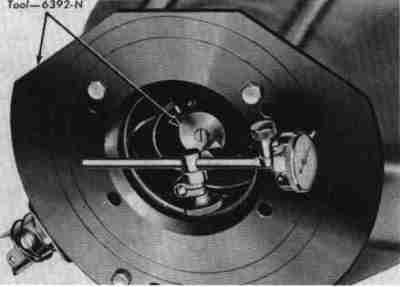

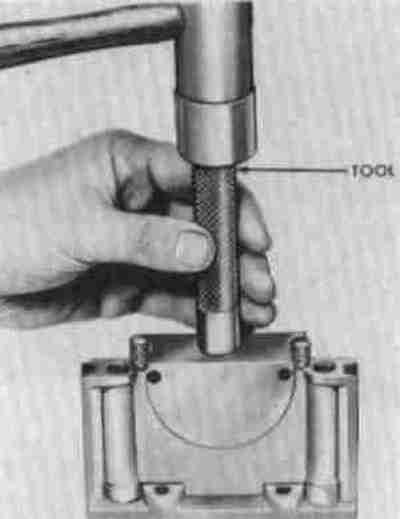

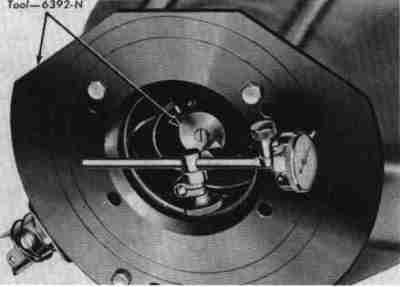

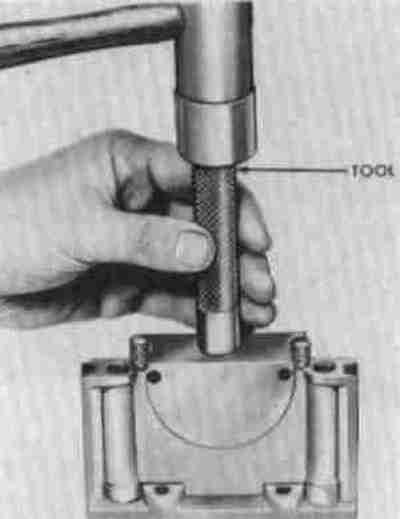

This tool was used for checking transmission misalignment.

This tool was used for checking transmission misalignment.

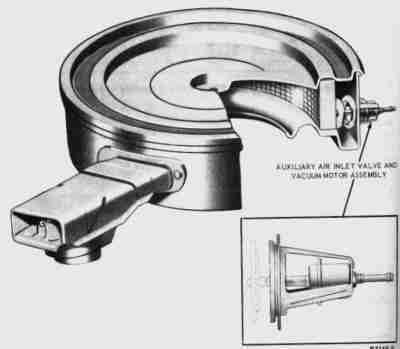

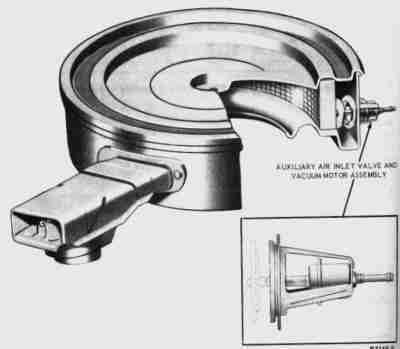

For some reason this is the only picture I can find of a Ford air filter

housing. Ford used this type from the late '60s through the early '80s.

If you're serious about performance, throw away that cheap open-element

filter, run down to the junkyard, and dig one of these babies up. They take

the big 14"x3" air filter element, have large radii at the carb inlet just

like those new carbon-fiber racing filter housings, and large inlet snorkels

already barbed to take ram-air hose, available off-the-shelf at almost any

parts store. Sure, Ford ran the inlet hose to the battery box or beside the

radiator, but you don't have to run it there. Most models have provision for

quick warm-up air coming off the exhaust manifolds.

For some reason this is the only picture I can find of a Ford air filter

housing. Ford used this type from the late '60s through the early '80s.

If you're serious about performance, throw away that cheap open-element

filter, run down to the junkyard, and dig one of these babies up. They take

the big 14"x3" air filter element, have large radii at the carb inlet just

like those new carbon-fiber racing filter housings, and large inlet snorkels

already barbed to take ram-air hose, available off-the-shelf at almost any

parts store. Sure, Ford ran the inlet hose to the battery box or beside the

radiator, but you don't have to run it there. Most models have provision for

quick warm-up air coming off the exhaust manifolds.

The snorkels are riveted on, so you can add an extra if you want... or pick up

one from an early Mustang GT, which had dual snorkels to start with... *and*

they were made out of aluminum and weighed almost nothing.

For some crazy reason people will pay $150 for an aftermarket ram air housing

that's not even near as nice as the factory part.

You might have to do some creative BFH work if you have a Holley with center-

hung float bowls, but it's well worth the effort. Why suck in all that hot

underhood air? Ford did these filter housings *right*.

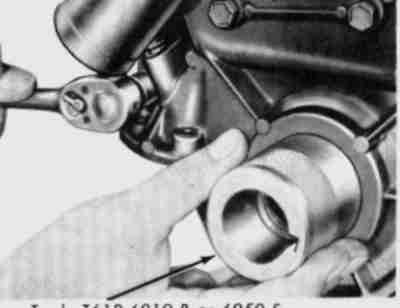

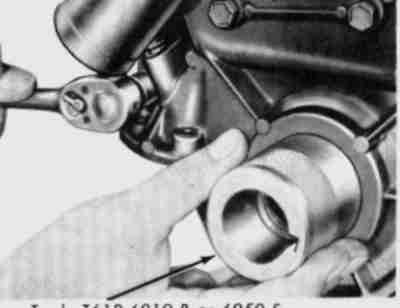

Ford makes this tool for centering the timing cover on pre-5.0 (non-doweled)

Windsors. Most rebuilders just slide the balancer on as far as it will go by

hand, tighten the cover, then finish installing the balancer.

Ford makes this tool for centering the timing cover on pre-5.0 (non-doweled)

Windsors. Most rebuilders just slide the balancer on as far as it will go by

hand, tighten the cover, then finish installing the balancer.

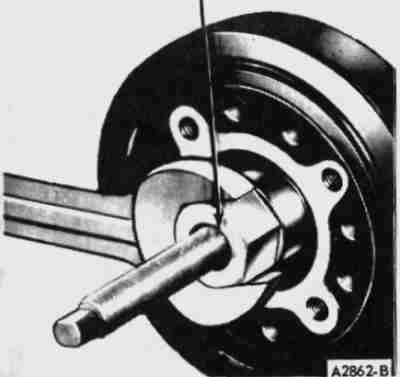

Here's how you're supposed to install the balancer on a Windsor. The

aftermarket didn't pick up on this for quite some years...

Here's how you're supposed to install the balancer on a Windsor. The

aftermarket didn't pick up on this for quite some years...

According to my 1975 Ford service manuals, Ford's 1975 Mustang II had an

auxiliary fuel tank as standard equipment, and the tank was optional on the

other Mustang II models. Auxiliary tanks were also available on the full-size

cars and wagons. I've never come across any of these, but they're pretty

nifty.

According to my 1975 Ford service manuals, Ford's 1975 Mustang II had an

auxiliary fuel tank as standard equipment, and the tank was optional on the

other Mustang II models. Auxiliary tanks were also available on the full-size

cars and wagons. I've never come across any of these, but they're pretty

nifty.

Ford had tools similar to this for every engine during the days of rope rear

main seals. You used this mandrel to hammer and shape the rope seal into the

block and cap grooves. You could install the seal with your fingers and

something to roll it in place, but the mandrel had a much better chance of

installing one that wouldn't leak.

Ford had tools similar to this for every engine during the days of rope rear

main seals. You used this mandrel to hammer and shape the rope seal into the

block and cap grooves. You could install the seal with your fingers and

something to roll it in place, but the mandrel had a much better chance of

installing one that wouldn't leak.

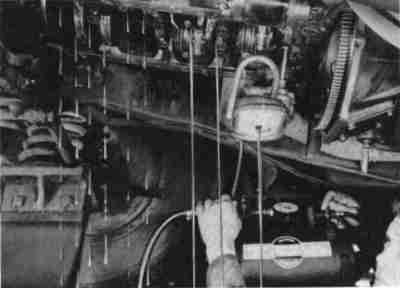

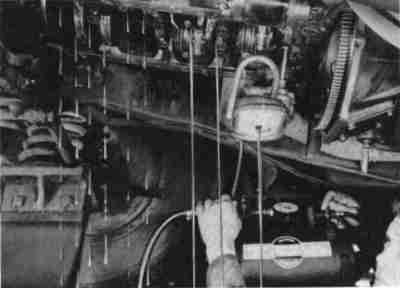

This isn't a Ford engine, and as far as I know Ford never recommended the

procedure, but it's so nifty I thought I'd include it anyway. This is an

engine undergoing an oil leak test. The pan is pulled and oil is forced into

the engine by compressed air. By measuring the side clearances of the

bearings with a feeler gauge and counting the number of drops of oil per

minute, the mechanic could tell the clearance of the rods and mains with a

high degree of accuracy. It looks really Mickey Mouse, but it's the same basic

procedure Ford uses at the factory to test brand new engines and automatic

transmissions.

This isn't a Ford engine, and as far as I know Ford never recommended the

procedure, but it's so nifty I thought I'd include it anyway. This is an

engine undergoing an oil leak test. The pan is pulled and oil is forced into

the engine by compressed air. By measuring the side clearances of the

bearings with a feeler gauge and counting the number of drops of oil per

minute, the mechanic could tell the clearance of the rods and mains with a

high degree of accuracy. It looks really Mickey Mouse, but it's the same basic

procedure Ford uses at the factory to test brand new engines and automatic

transmissions.

The main problem with the leak test nowadays is there are so few cars where

it's practical to get the pan off without having to pull the whole engine out.

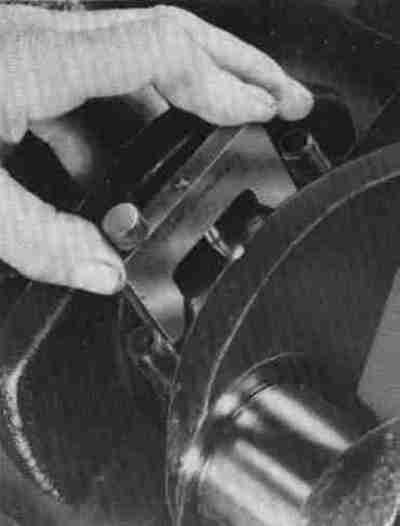

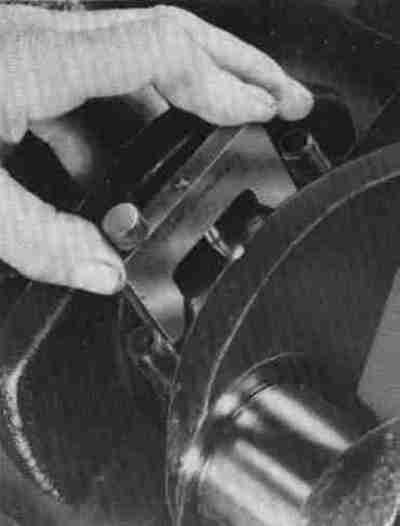

This is a crank journal diameter gauge. Perfect Circle made them at least

through the 1950s. Ford approved of and recommended using them for servicing

Ford engines. Unfortunately Perfect Circle doesn't make them any more, and

I've never managed to quite figure out how they work. It would be a nice tool

to take a quick reading of a journal you can't get a mike to for some reason.

This is a crank journal diameter gauge. Perfect Circle made them at least

through the 1950s. Ford approved of and recommended using them for servicing

Ford engines. Unfortunately Perfect Circle doesn't make them any more, and

I've never managed to quite figure out how they work. It would be a nice tool

to take a quick reading of a journal you can't get a mike to for some reason.

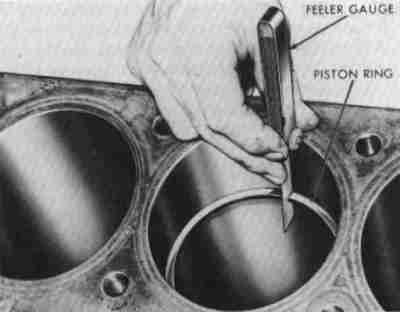

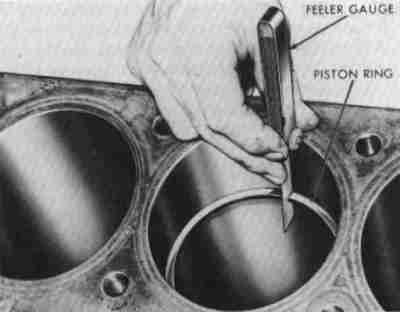

This image is supposed to show you how to check the ring gap, but it will do

as well for showing you another way to check the bore diameter. Procure a

ring in your bore size - most rebuilders will give you all the used rings you

want - and find a block with the same bore as yours; preferably freshly

machined and gauged by the machine shop. It doesn't have to be the same brand

of ring or block, just the same bore size. Insert the ring squarely in the

bore - an old piston works well as a squaring tool - and use your feelers to

check the ring gap. Assuming your block has a bore of 4.030" and your gap is

.029", .029" is your base figure. Since the diameter and circumference are

related by the constant 'pi', or 3.1416, the gap will open up .0031416" for

every .001" of larger bore, or vice versa. The 3:1 ratio is easy to work

with; it's easy to check down to a half-thousandths with feelers, which will

give your the bore size to a couple of tenths. Not bad, eh?

This image is supposed to show you how to check the ring gap, but it will do

as well for showing you another way to check the bore diameter. Procure a

ring in your bore size - most rebuilders will give you all the used rings you

want - and find a block with the same bore as yours; preferably freshly

machined and gauged by the machine shop. It doesn't have to be the same brand

of ring or block, just the same bore size. Insert the ring squarely in the

bore - an old piston works well as a squaring tool - and use your feelers to

check the ring gap. Assuming your block has a bore of 4.030" and your gap is

.029", .029" is your base figure. Since the diameter and circumference are

related by the constant 'pi', or 3.1416, the gap will open up .0031416" for

every .001" of larger bore, or vice versa. The 3:1 ratio is easy to work

with; it's easy to check down to a half-thousandths with feelers, which will

give your the bore size to a couple of tenths. Not bad, eh?

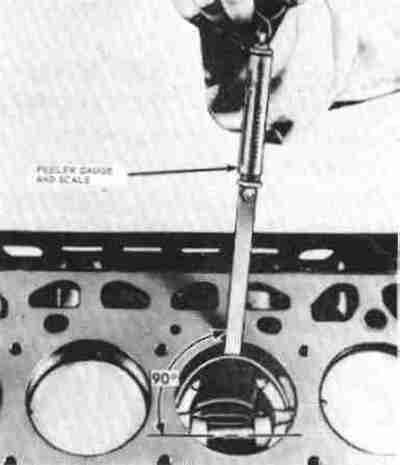

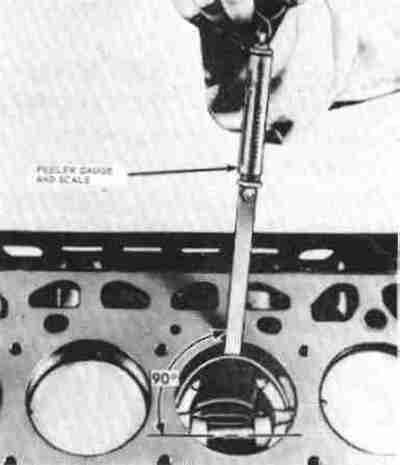

This is Ford's recommended way of measuring piston-to-bore clearance. The

bore is lubricated with oil, the piston and feeler gauge inserted, and a

special scale (a fish scale, except with a clamp to attach it to the feeler)

is used to measure the drag as the gauge is pulled out.

This is Ford's recommended way of measuring piston-to-bore clearance. The

bore is lubricated with oil, the piston and feeler gauge inserted, and a

special scale (a fish scale, except with a clamp to attach it to the feeler)

is used to measure the drag as the gauge is pulled out.

Under controlled conditions, with a known cylinder finish and specific

lubricant, the feeler drag method can be very accurate. Under uncontrolled

conditions with an inexperienced mechanic it's still accurate enough to

measure within half a thousandth.

Ford specifies a *run-in* bore, that is, one from a used engine that has worn

all the sharp honing peaks off. Using plain 30-weight oil, use a feeler gauge

1.2 inch wide, 6 inches long, and .0035" thick. Put the feeler perpendicular

to the piston pin and parallel with the bore axis, and pull the feeler out

with a slow, smooth stroke while watching the spring scale. It may take

several tries to get a repeatable reading.

Ford's chart specifies:

Pull Clearance

12 lb. .0014 in.

10 lb. .0018 in.

8 lb. .0023 in.

7 lb. .0025 in.

6 lb. .0027 in.

5 lb. .0030 in.

4 lb. .0032 in.

3 lb. .0033 in.

2 lb. .0036 in.

1 lb. .0038 in.

Note you can actually measure clearances larger than the thickness of the

feeler; this is an effect of the viscosity of the lubricant.

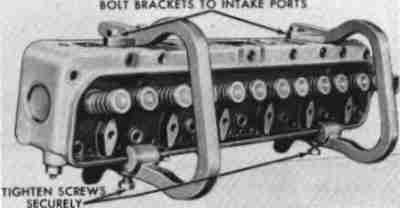

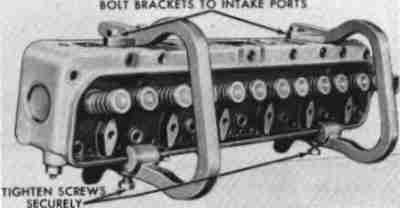

These nifty little brackets were for servicing FE heads. Back in the old days

valve jobs at 20,000 mile intervals weren't uncommon, so tools like this were

handy for holding the head securely while chiseling carbon, grinding seats,

etc.

These nifty little brackets were for servicing FE heads. Back in the old days

valve jobs at 20,000 mile intervals weren't uncommon, so tools like this were

handy for holding the head securely while chiseling carbon, grinding seats,

etc.

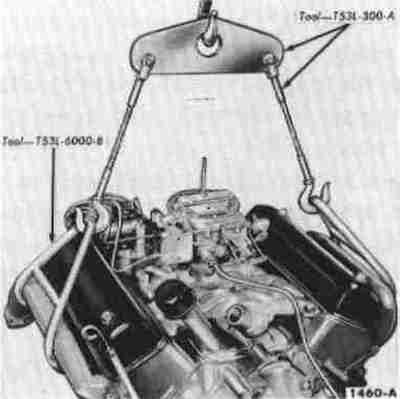

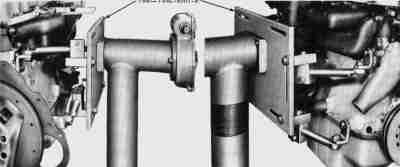

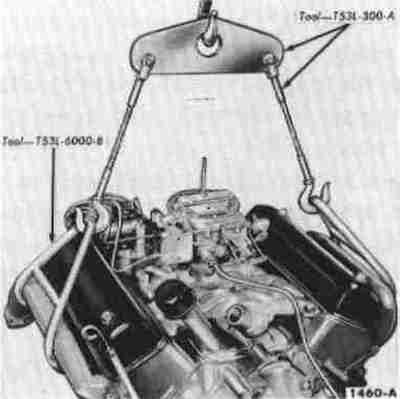

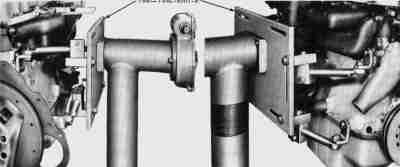

This set of brackets was to be used to lifting the Y-Block engines. Ford

didn't want people using any old bolt holes to lift it.

This set of brackets was to be used to lifting the Y-Block engines. Ford

didn't want people using any old bolt holes to lift it.

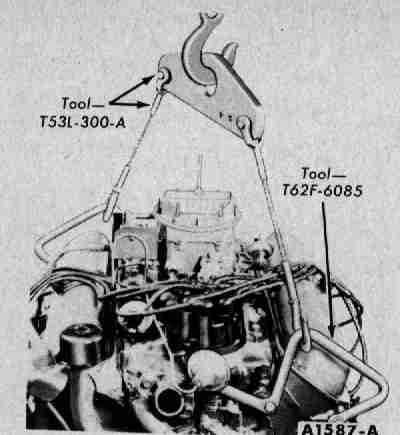

This set of brackets was to be used to lifting the early Windsor engines.

This set of brackets was to be used to lifting the early Windsor engines.

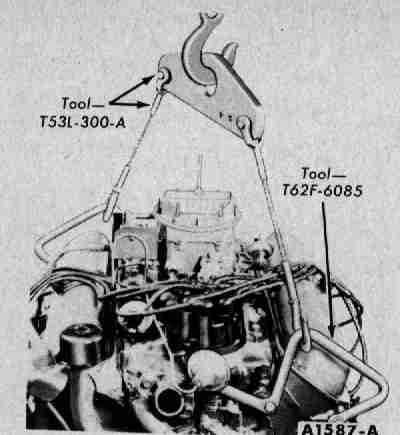

Ford had a custom bracket for everything. This one grabs under the small

six's manifolds to lift it out of the engine compartment.

Ford had a custom bracket for everything. This one grabs under the small

six's manifolds to lift it out of the engine compartment.

Head removal and holding tools for 223 Six. A convenient set of handles for

lifting the head off or back on the engine, and fixtures for holding the head

for service.

Head removal and holding tools for 223 Six. A convenient set of handles for

lifting the head off or back on the engine, and fixtures for holding the head

for service.

Ford engine stands always grab the engine from the side and use a worm gear

setup to rotate the engine end-for-end. They've done this ever since the days

of the flatheads. I've never seen one for sale, but I bet this official Ford

tool costs as much as a rebuilt engine...

Ford engine stands always grab the engine from the side and use a worm gear

setup to rotate the engine end-for-end. They've done this ever since the days

of the flatheads. I've never seen one for sale, but I bet this official Ford

tool costs as much as a rebuilt engine...

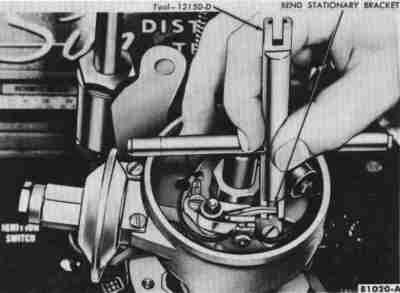

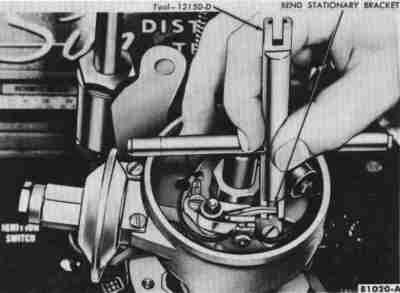

When setting points on a Ford, you were supposed to bend the point arm with

this special Ford tool instead of loosening the screw. I bet you didn't know

that.

When setting points on a Ford, you were supposed to bend the point arm with

this special Ford tool instead of loosening the screw. I bet you didn't know

that.

Kuntz and Craft of Arkadelphia, Arkansas used to make these nifty little

gimmers circa 1993. They had them for the 429/460, Cleveland, Windsor, and FE

engines. Just the trick to clear a blower snout or a trick independent runner

induction system.

Kuntz and Craft of Arkadelphia, Arkansas used to make these nifty little

gimmers circa 1993. They had them for the 429/460, Cleveland, Windsor, and FE

engines. Just the trick to clear a blower snout or a trick independent runner

induction system.

Here's a shot of the inside of the offset housing. Small timing belt is all

you need to turn the rotor.

Here's a shot of the inside of the offset housing. Small timing belt is all

you need to turn the rotor.

This adapter plate was available from McLeod in 1985. It lets you put a T5 up

against a TopLoader bellhousing.

This adapter plate was available from McLeod in 1985. It lets you put a T5 up

against a TopLoader bellhousing.

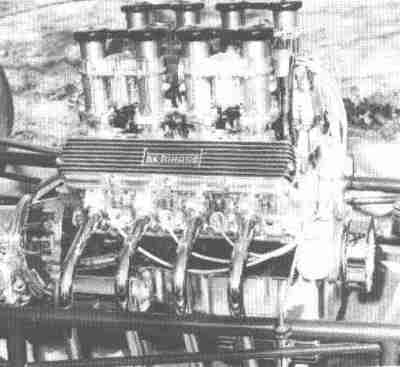

This interesting image appears on the flyleaf of "The Chevrolet Racing Engine"

by Grumpy Jenkins. That's a Chevy block. And that's a Weiand tunnel ram for

a 351 Cleveland. Hmm...

This interesting image appears on the flyleaf of "The Chevrolet Racing Engine"

by Grumpy Jenkins. That's a Chevy block. And that's a Weiand tunnel ram for

a 351 Cleveland. Hmm...

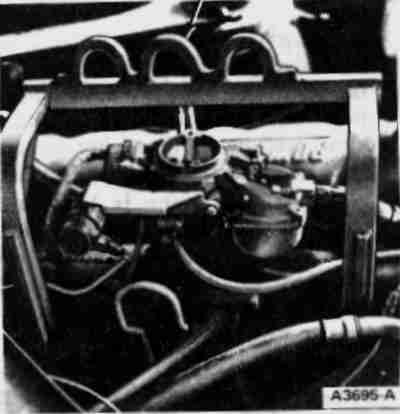

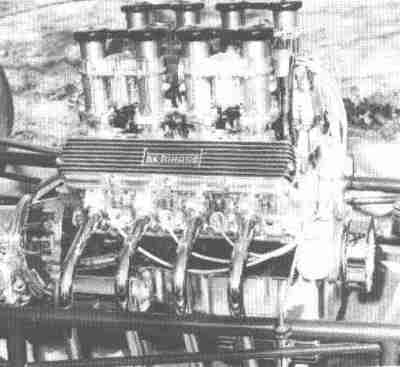

These ultra-rare Weslake heads were intended for the DeTomaso Mangusta. None

made it into Mangustas from the factory; this pair is on a 289 or 302 in a

street rod. The very small header tubes were probably the work the the car

builder.

These ultra-rare Weslake heads were intended for the DeTomaso Mangusta. None

made it into Mangustas from the factory; this pair is on a 289 or 302 in a

street rod. The very small header tubes were probably the work the the car

builder.

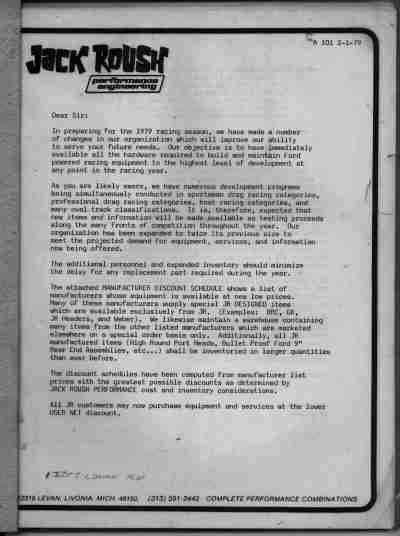

How about a 1979 Roush catalog? Just after his breakup with Wayne Gapp, many

part numbers still start with "GRxx".

How about a 1979 Roush catalog? Just after his breakup with Wayne Gapp, many

part numbers still start with "GRxx".

This is the cast iron, curved-vane water pump impeller the old Muscle Parts

catalog recommended for upgrading your racing BOSS 351. It's still in the

catalog as M-8512-A302. I tried to purchase one in 1995. The best price I

could find was around $50. Then I found out there are half a dozen different

housings with different internal shapes; the impeller was designed for the M-

8505-A331 aluminum housing ($150) and there are major differences among the

rest of the small block housings. It's easier just to buy a whole aftermarket

pump with a good impeller instead of a sheet metal paddle.

This is the cast iron, curved-vane water pump impeller the old Muscle Parts

catalog recommended for upgrading your racing BOSS 351. It's still in the

catalog as M-8512-A302. I tried to purchase one in 1995. The best price I

could find was around $50. Then I found out there are half a dozen different

housings with different internal shapes; the impeller was designed for the M-

8505-A331 aluminum housing ($150) and there are major differences among the

rest of the small block housings. It's easier just to buy a whole aftermarket

pump with a good impeller instead of a sheet metal paddle.

Early rodders often ran dual-fuel setups. This Ford coupe has a 5-gallon

aluminum tank with high-octane racing fuel. Hand-operated plunger pump

pressurizes tank to 6 PSI to ensure positive pressure to get fuel to the main

fuel pump.

Early rodders often ran dual-fuel setups. This Ford coupe has a 5-gallon

aluminum tank with high-octane racing fuel. Hand-operated plunger pump

pressurizes tank to 6 PSI to ensure positive pressure to get fuel to the main

fuel pump.

Okay, not a Ford-specific part. This Eelco cleanable oil filter was available

in 1961. It, or copies of it, have been available under half a dozen names

since. I still think that screen is some kind of commonly-available part you

could probably find in a hydraulic shop.

Okay, not a Ford-specific part. This Eelco cleanable oil filter was available

in 1961. It, or copies of it, have been available under half a dozen names

since. I still think that screen is some kind of commonly-available part you

could probably find in a hydraulic shop.

Ford used this remote-mount power brake booster setup in 1957-1959 models.

Many of the remote-booster street rod conversions use these parts.

Ford used this remote-mount power brake booster setup in 1957-1959 models.

Many of the remote-booster street rod conversions use these parts.

Ford added this harmonic-balancer-style vibration damper to the front yoke of

some models beginning in 1967. The damper was just another step in

controlling what Ford calls "NVH", for "Noise, Vibration, and Harshness."

Ford added this harmonic-balancer-style vibration damper to the front yoke of

some models beginning in 1967. The damper was just another step in

controlling what Ford calls "NVH", for "Noise, Vibration, and Harshness."

This tool was used for checking transmission misalignment.

This tool was used for checking transmission misalignment.

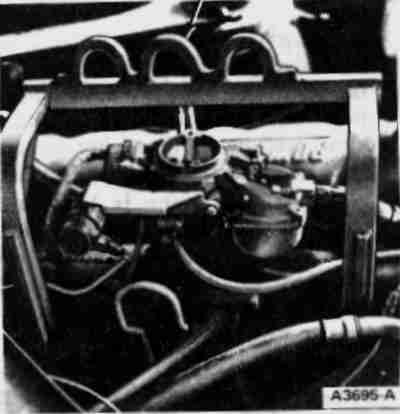

For some reason this is the only picture I can find of a Ford air filter

housing. Ford used this type from the late '60s through the early '80s.

If you're serious about performance, throw away that cheap open-element

filter, run down to the junkyard, and dig one of these babies up. They take

the big 14"x3" air filter element, have large radii at the carb inlet just

like those new carbon-fiber racing filter housings, and large inlet snorkels

already barbed to take ram-air hose, available off-the-shelf at almost any

parts store. Sure, Ford ran the inlet hose to the battery box or beside the

radiator, but you don't have to run it there. Most models have provision for

quick warm-up air coming off the exhaust manifolds.

For some reason this is the only picture I can find of a Ford air filter

housing. Ford used this type from the late '60s through the early '80s.

If you're serious about performance, throw away that cheap open-element

filter, run down to the junkyard, and dig one of these babies up. They take

the big 14"x3" air filter element, have large radii at the carb inlet just

like those new carbon-fiber racing filter housings, and large inlet snorkels

already barbed to take ram-air hose, available off-the-shelf at almost any

parts store. Sure, Ford ran the inlet hose to the battery box or beside the

radiator, but you don't have to run it there. Most models have provision for

quick warm-up air coming off the exhaust manifolds.

Ford makes this tool for centering the timing cover on pre-5.0 (non-doweled)

Windsors. Most rebuilders just slide the balancer on as far as it will go by

hand, tighten the cover, then finish installing the balancer.

Ford makes this tool for centering the timing cover on pre-5.0 (non-doweled)

Windsors. Most rebuilders just slide the balancer on as far as it will go by

hand, tighten the cover, then finish installing the balancer.

Here's how you're supposed to install the balancer on a Windsor. The

aftermarket didn't pick up on this for quite some years...

Here's how you're supposed to install the balancer on a Windsor. The

aftermarket didn't pick up on this for quite some years...

According to my 1975 Ford service manuals, Ford's 1975 Mustang II had an

auxiliary fuel tank as standard equipment, and the tank was optional on the

other Mustang II models. Auxiliary tanks were also available on the full-size

cars and wagons. I've never come across any of these, but they're pretty

nifty.

According to my 1975 Ford service manuals, Ford's 1975 Mustang II had an

auxiliary fuel tank as standard equipment, and the tank was optional on the

other Mustang II models. Auxiliary tanks were also available on the full-size

cars and wagons. I've never come across any of these, but they're pretty

nifty.

Ford had tools similar to this for every engine during the days of rope rear

main seals. You used this mandrel to hammer and shape the rope seal into the

block and cap grooves. You could install the seal with your fingers and

something to roll it in place, but the mandrel had a much better chance of

installing one that wouldn't leak.

Ford had tools similar to this for every engine during the days of rope rear

main seals. You used this mandrel to hammer and shape the rope seal into the

block and cap grooves. You could install the seal with your fingers and

something to roll it in place, but the mandrel had a much better chance of

installing one that wouldn't leak.

This isn't a Ford engine, and as far as I know Ford never recommended the

procedure, but it's so nifty I thought I'd include it anyway. This is an

engine undergoing an oil leak test. The pan is pulled and oil is forced into

the engine by compressed air. By measuring the side clearances of the

bearings with a feeler gauge and counting the number of drops of oil per

minute, the mechanic could tell the clearance of the rods and mains with a

high degree of accuracy. It looks really Mickey Mouse, but it's the same basic

procedure Ford uses at the factory to test brand new engines and automatic

transmissions.

This isn't a Ford engine, and as far as I know Ford never recommended the

procedure, but it's so nifty I thought I'd include it anyway. This is an

engine undergoing an oil leak test. The pan is pulled and oil is forced into

the engine by compressed air. By measuring the side clearances of the

bearings with a feeler gauge and counting the number of drops of oil per

minute, the mechanic could tell the clearance of the rods and mains with a

high degree of accuracy. It looks really Mickey Mouse, but it's the same basic

procedure Ford uses at the factory to test brand new engines and automatic

transmissions.

This is a crank journal diameter gauge. Perfect Circle made them at least

through the 1950s. Ford approved of and recommended using them for servicing

Ford engines. Unfortunately Perfect Circle doesn't make them any more, and

I've never managed to quite figure out how they work. It would be a nice tool

to take a quick reading of a journal you can't get a mike to for some reason.

This is a crank journal diameter gauge. Perfect Circle made them at least

through the 1950s. Ford approved of and recommended using them for servicing

Ford engines. Unfortunately Perfect Circle doesn't make them any more, and

I've never managed to quite figure out how they work. It would be a nice tool

to take a quick reading of a journal you can't get a mike to for some reason.

This image is supposed to show you how to check the ring gap, but it will do

as well for showing you another way to check the bore diameter. Procure a

ring in your bore size - most rebuilders will give you all the used rings you

want - and find a block with the same bore as yours; preferably freshly

machined and gauged by the machine shop. It doesn't have to be the same brand

of ring or block, just the same bore size. Insert the ring squarely in the

bore - an old piston works well as a squaring tool - and use your feelers to

check the ring gap. Assuming your block has a bore of 4.030" and your gap is

.029", .029" is your base figure. Since the diameter and circumference are

related by the constant 'pi', or 3.1416, the gap will open up .0031416" for

every .001" of larger bore, or vice versa. The 3:1 ratio is easy to work

with; it's easy to check down to a half-thousandths with feelers, which will

give your the bore size to a couple of tenths. Not bad, eh?

This image is supposed to show you how to check the ring gap, but it will do

as well for showing you another way to check the bore diameter. Procure a

ring in your bore size - most rebuilders will give you all the used rings you

want - and find a block with the same bore as yours; preferably freshly

machined and gauged by the machine shop. It doesn't have to be the same brand

of ring or block, just the same bore size. Insert the ring squarely in the

bore - an old piston works well as a squaring tool - and use your feelers to

check the ring gap. Assuming your block has a bore of 4.030" and your gap is

.029", .029" is your base figure. Since the diameter and circumference are

related by the constant 'pi', or 3.1416, the gap will open up .0031416" for

every .001" of larger bore, or vice versa. The 3:1 ratio is easy to work

with; it's easy to check down to a half-thousandths with feelers, which will

give your the bore size to a couple of tenths. Not bad, eh?

This is Ford's recommended way of measuring piston-to-bore clearance. The

bore is lubricated with oil, the piston and feeler gauge inserted, and a

special scale (a fish scale, except with a clamp to attach it to the feeler)

is used to measure the drag as the gauge is pulled out.

This is Ford's recommended way of measuring piston-to-bore clearance. The

bore is lubricated with oil, the piston and feeler gauge inserted, and a

special scale (a fish scale, except with a clamp to attach it to the feeler)

is used to measure the drag as the gauge is pulled out.

These nifty little brackets were for servicing FE heads. Back in the old days

valve jobs at 20,000 mile intervals weren't uncommon, so tools like this were

handy for holding the head securely while chiseling carbon, grinding seats,

etc.

These nifty little brackets were for servicing FE heads. Back in the old days

valve jobs at 20,000 mile intervals weren't uncommon, so tools like this were

handy for holding the head securely while chiseling carbon, grinding seats,

etc.

This set of brackets was to be used to lifting the Y-Block engines. Ford

didn't want people using any old bolt holes to lift it.

This set of brackets was to be used to lifting the Y-Block engines. Ford

didn't want people using any old bolt holes to lift it.

This set of brackets was to be used to lifting the early Windsor engines.

This set of brackets was to be used to lifting the early Windsor engines.

Ford had a custom bracket for everything. This one grabs under the small

six's manifolds to lift it out of the engine compartment.

Ford had a custom bracket for everything. This one grabs under the small

six's manifolds to lift it out of the engine compartment.

Head removal and holding tools for 223 Six. A convenient set of handles for

lifting the head off or back on the engine, and fixtures for holding the head

for service.

Head removal and holding tools for 223 Six. A convenient set of handles for

lifting the head off or back on the engine, and fixtures for holding the head

for service.

Ford engine stands always grab the engine from the side and use a worm gear

setup to rotate the engine end-for-end. They've done this ever since the days

of the flatheads. I've never seen one for sale, but I bet this official Ford

tool costs as much as a rebuilt engine...

Ford engine stands always grab the engine from the side and use a worm gear

setup to rotate the engine end-for-end. They've done this ever since the days

of the flatheads. I've never seen one for sale, but I bet this official Ford

tool costs as much as a rebuilt engine...

When setting points on a Ford, you were supposed to bend the point arm with

this special Ford tool instead of loosening the screw. I bet you didn't know

that.

When setting points on a Ford, you were supposed to bend the point arm with

this special Ford tool instead of loosening the screw. I bet you didn't know

that.

Kuntz and Craft of Arkadelphia, Arkansas used to make these nifty little

gimmers circa 1993. They had them for the 429/460, Cleveland, Windsor, and FE

engines. Just the trick to clear a blower snout or a trick independent runner

induction system.

Kuntz and Craft of Arkadelphia, Arkansas used to make these nifty little

gimmers circa 1993. They had them for the 429/460, Cleveland, Windsor, and FE

engines. Just the trick to clear a blower snout or a trick independent runner

induction system.

Here's a shot of the inside of the offset housing. Small timing belt is all

you need to turn the rotor.

Here's a shot of the inside of the offset housing. Small timing belt is all

you need to turn the rotor.

This adapter plate was available from McLeod in 1985. It lets you put a T5 up

against a TopLoader bellhousing.

This adapter plate was available from McLeod in 1985. It lets you put a T5 up

against a TopLoader bellhousing.

This interesting image appears on the flyleaf of "The Chevrolet Racing Engine"

by Grumpy Jenkins. That's a Chevy block. And that's a Weiand tunnel ram for

a 351 Cleveland. Hmm...

This interesting image appears on the flyleaf of "The Chevrolet Racing Engine"

by Grumpy Jenkins. That's a Chevy block. And that's a Weiand tunnel ram for

a 351 Cleveland. Hmm...

These ultra-rare Weslake heads were intended for the DeTomaso Mangusta. None

made it into Mangustas from the factory; this pair is on a 289 or 302 in a

street rod. The very small header tubes were probably the work the the car

builder.

These ultra-rare Weslake heads were intended for the DeTomaso Mangusta. None

made it into Mangustas from the factory; this pair is on a 289 or 302 in a

street rod. The very small header tubes were probably the work the the car

builder.

How about a 1979 Roush catalog? Just after his breakup with Wayne Gapp, many

part numbers still start with "GRxx".

How about a 1979 Roush catalog? Just after his breakup with Wayne Gapp, many

part numbers still start with "GRxx".