brought to you by: Dave Williams

This page: www.bacomatic.org/~dw/fordv8/windsor/windsor.htm

Main page:

http://www.bacomatic.org/~dw/index.htm

Last Updated: 18 Sep 2003

Author: Dave Williams; dlwilliams=aristotle=net

displacement 221 255 260 289 302 351W years made bore 4.0" 4.0" 4.0" stroke 2.87" 3.0" 3.5" deck height 8.206" 8.206" 8.206" 8.206" 8.206" 9.50" rod length 5.15" 5.15" 5.15" 5.15" 5.09" 5.956" pin height pin diameter .912" .912" .912" .912" .912" .912" pin offset .0625" .0625" length width height weight 460 (221-302), 500 (BOSS 302), 525 (351W) [Peterson Pub.] bore spacing

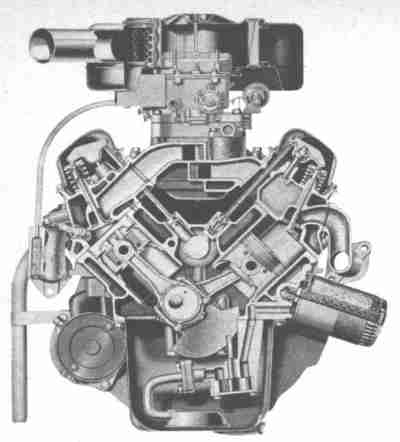

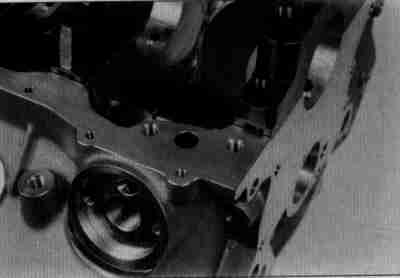

221 Fairlane engine. Note generous water jacketing, road draft tube.

221 Fairlane engine. Note generous water jacketing, road draft tube.

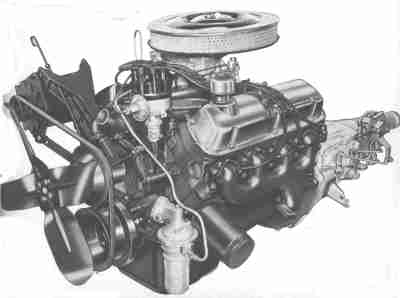

This 1964 image is a 260 from a Fairlane. Note the stout generator bracket,

aluminum water pump, spin-on fuel filter, and the unusual inward tilt of the

driver's side exhaust manifold. That's a Borg/Warner T-10 four speed in back.

The carburetor under the jaunty open-element air filter is an ordinary

Autolite two barrel.

This 1964 image is a 260 from a Fairlane. Note the stout generator bracket,

aluminum water pump, spin-on fuel filter, and the unusual inward tilt of the

driver's side exhaust manifold. That's a Borg/Warner T-10 four speed in back.

The carburetor under the jaunty open-element air filter is an ordinary

Autolite two barrel.

"Complete Book Of Engines No. 2" from 1966 "289 C.I.D. Mustang Competition Engine Specifications" Piston to bore .......................................... .0042 - .0048 Top of block to piston .................................. .015 - .018 Connecting rod, vertical clearance ...................... .0015 - .003 Side clearance, total 2 rods ............................ .014 - .024 Main bearings vertical clearance ........................ .0022 - .0025 End clearance ........................................... .006 - .008 Head volume C.C.'s ...................................... 44-48 Compression ratio ....................................... 10.5 - 10.8:1 Carburetor .......................................... Holley No. 2668 Primary Venturi .............................................. 1 5/16 Secondary Venturi ............................................. 1 3/8 Throttle Bore ............................................... 1 11/16 Nominal Flow @ 1 1/2-in. hg. ................................ 715 CFM Primary Jets ................................................. #67-70 Secondary Jets ............................................... #78-82 Note: High numbered jets are high flow, low numbered jets are low flow. Valve spring pressures -- 110 lbs. - 120 lbs. @ 1.770" Valve clearance -- int. .018 ex. .020 (hot) Spark plugs ......................... Autolite BTF1, BF603, BF601, BF12 Ignition timing ................. 10 - 12 deg initial 36 - 38 deg total Point clearance ........................................... .016 - .018 Dwell ..................................... 25 deg /point, 33 deg total Recommended oil ................ S.A.E. 40W non-detergent, Castrol R-40

"Complete Book Of Engines No. 2" from 1966

"289 C.I.D. Cobra Competition Engine Specifications"

Piston to bore .......................................... .0042 - .0048

Top of block to piston .................................. .015 - .018

Connecting rod, vertical clearance ...................... .0015 - .003

Side clearance, total 2 rods ............................ .014 - .024

Main bearings vertical clearance ........................ .0022 - .0025

End clearance ........................................... .006 - .008

Valve lift ...................................................... .500"

Valve timing ................................ Int. Op. .... 37 deg BTDC

Int. Cl ..... 72 deg ABDC

Exh. Op ..... 76 deg BBDC

Exh. Cl ..... 32 deg ATDC

50 - 60

Above checked at .025 clearance Int. @ Exh, @ .001 valve lift

Head colume in C.C.'s ........................................... 44-48

Compression ratio ....................................... 10.5 - 10.8:1

Carburetion: 4--48 I.D.A.I. Weber

Main Jets ................................................. 150 - 170

Air corr. jets ............................................ 100 - 150

Emulsion tube .................................................... F7

Choke size ................................................... 42 mm.

Float level .................... Top of float 6mm. above bowl surface

with carburetor top removed

Fuel pressure .......................................... 4 - 5 P.S.I.

Valve settings ............................. Int. .025, Exh. .025 (hot)

Valve spring pressures ..... 110 lbs. - 120 lbs. @ 1.770" loaded height

Spark plugs ............................... Autolite BTF1, BF603, BF601

Ignition timing ................ 10 - 12 deg initial, 36 - 38 deg total

Point clearance ........................................... .016 - .018

Recommended oil ..................... S.A.E. 50W mineral or Castrol R40

"Complete Book Of Engines No. 2" from 1966

Thread Installation

Operation Size Torque

Bolt -- Rocker arm cover to cylinder head ............ 1/4-20 3-5 ft.lbs.

Bolt -- Oil pan ......................................

Bolt -- Pressure plate to flywheel ................... 5/16-18 12-20 ft.lbs.

Bolt -- Cam sprocket to camshaft ..................... 3/8-16 30-35 ft.lbs.

Nut -- Rocker arm adjusting ..........................

Bolt -- Flywheel to crankshaft ....................... 7/16-20 78-85 ft.lbs.

Bolt -- Main bearing cap ............................. 7/16-14 60-70 ft.lbs.

Plug -- Oil pan drain ................................ 1/2-20 15-20 ft.lbs.

Bolt -- Crankshaft damper to crankshaft (hand start

-- run down with impact wrench ............... 5/8-18 120-140 ft.lbs.

Spark plug ........................................... 18MM 12-25 ft.lbs.

Oil filter cartridge ................ Tighten 1/2 turn after gasket contact

Insert -- Oil filter mounting to block ............... 1-1/16-12 60-100 ft.lbs.

Bolt -- Exhaust manifold to cylinder head ............ 3/8-16 13-18 ft.lbs.

Nut -- Carburetor mounting ........................... 5/16-24 12-15 ft.lbs.

Bolt -- Distributor hold down ........................ 5/16-18 12-15 ft.lbs.

Bolt -- Generator bracket to cyl. head ............... 3/8-16 30-35 ft.lbs.

Bolt -- Front cover .................................. 5/16-18 12-15 ft.lbs.

Bolt -- Oil filler tube bracket to generator bracket

(hand start and run-down with impact wrench) . 1/4-20 6-9 ft.lbs.

Nut -- Connecting rod

Hand torque 40-45 lbs. ............................... 3/8-24 40-45 ft.lbs.ref.

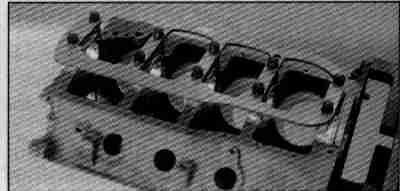

Shelby 289 exhaust ports. Note how the port roof has been raused as much as

possible.

Shelby 289 exhaust ports. Note how the port roof has been raused as much as

possible.

Shelby 289 head after plunge cutting to unshroud the valves. The plug side of

the wall was usually laid back a bit further before the heads were sent off to

have the coolant passages welded up.

Shelby 289 head after plunge cutting to unshroud the valves. The plug side of

the wall was usually laid back a bit further before the heads were sent off to

have the coolant passages welded up.

Shelby 289 cooling passage mod. Shelby's engine builders welded up the

coolant passage in an effort to reinforce the deck and reduce the chance of

blowing head gaskets.

Shelby 289 cooling passage mod. Shelby's engine builders welded up the

coolant passage in an effort to reinforce the deck and reduce the chance of

blowing head gaskets.

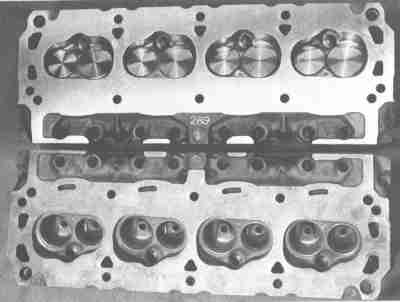

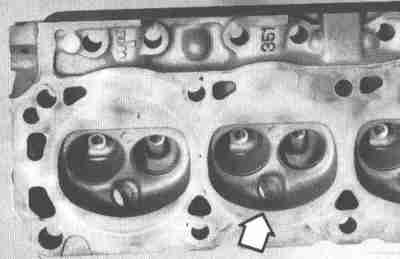

The C9OE or D0OE heads are useful for 289s, 302s, and small strokers,

depending on how much you want to put into porting. These heads are directly

interchangeable and identical other than the casting numbers; it's not

uncommon to find one of each on an all-original 351. Arrow points to

crescent-shaped quench area on plug side outlined by the gasket imprint.

The C9OE or D0OE heads are useful for 289s, 302s, and small strokers,

depending on how much you want to put into porting. These heads are directly

interchangeable and identical other than the casting numbers; it's not

uncommon to find one of each on an all-original 351. Arrow points to

crescent-shaped quench area on plug side outlined by the gasket imprint.

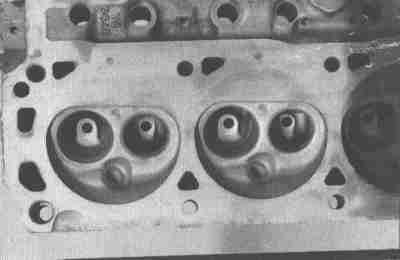

This is the D7OE large-chamber 351W head. The D7OE heads are useful for

larger strokers. It's hard to get compression *out* of a 377 or larger

Windsor! The ports and valves are identical to the C9 and D0 heads. Note the

lack of the outboard quench area compared to the early heads.

This is the D7OE large-chamber 351W head. The D7OE heads are useful for

larger strokers. It's hard to get compression *out* of a 377 or larger

Windsor! The ports and valves are identical to the C9 and D0 heads. Note the

lack of the outboard quench area compared to the early heads.

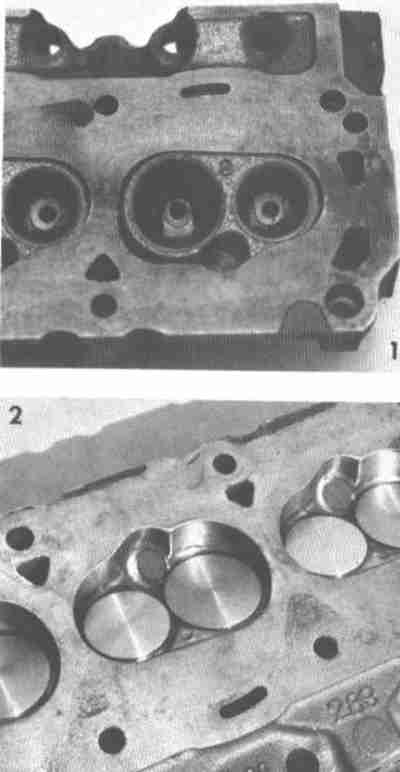

260 cylinder head. Note small valves, very tight chamber. A pair of these

will raise the compression ratio of a 302 or 5.0 right on up there, but the

ports and valves are proportionally smaller, so there'd be no real gain from

doing so.

260 cylinder head. Note small valves, very tight chamber. A pair of these

will raise the compression ratio of a 302 or 5.0 right on up there, but the

ports and valves are proportionally smaller, so there'd be no real gain from

doing so.

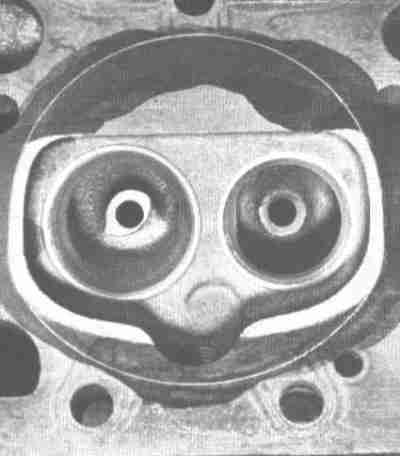

This is the 289 4V small combustion chamber, which is characterized by the

outboard chamber walls being pulled in and leaving the plug in a pocket. A

handful of early 302 4V also got these heads. A common casting number is

C6AE. These work nicely on 302 and 5.0 engines, usually worth a full ratio of

increased compression.

This is the 289 4V small combustion chamber, which is characterized by the

outboard chamber walls being pulled in and leaving the plug in a pocket. A

handful of early 302 4V also got these heads. A common casting number is

C6AE. These work nicely on 302 and 5.0 engines, usually worth a full ratio of

increased compression.

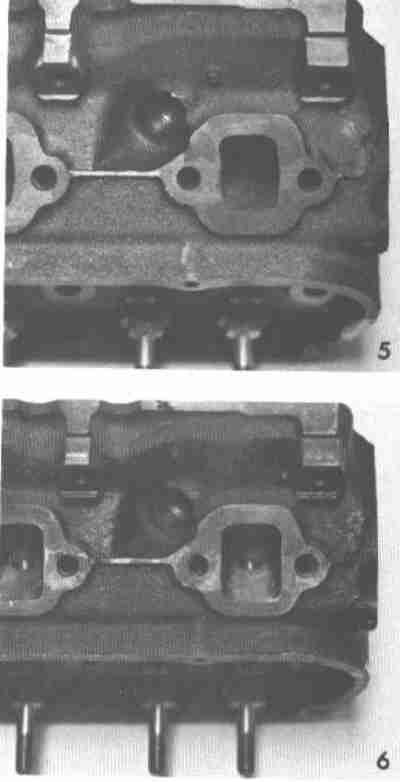

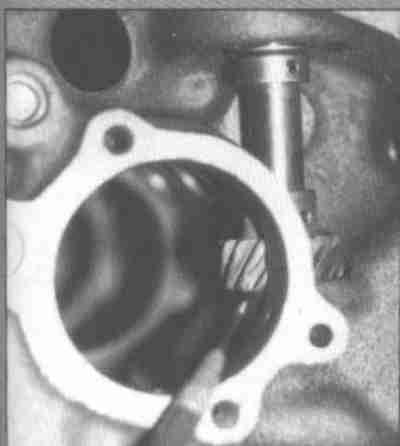

This image from Ford shows the difference in the intake water ports between

the small Windsors and the early 351s. The pictures are upside down for some

reason. Ford itself is the origin of the claim that ordinary 302 gaskets

won't seal with Windsor heads. In actuality they work just fine; the extra

intake bolt holes are blind and no water can leak through.

This image from Ford shows the difference in the intake water ports between

the small Windsors and the early 351s. The pictures are upside down for some

reason. Ford itself is the origin of the claim that ordinary 302 gaskets

won't seal with Windsor heads. In actuality they work just fine; the extra

intake bolt holes are blind and no water can leak through.

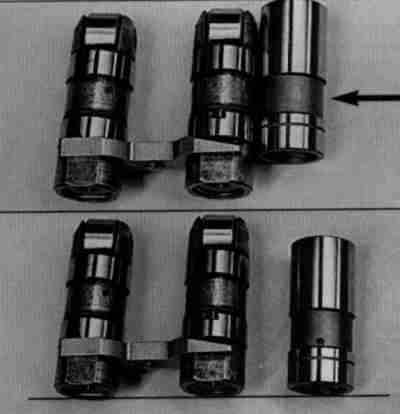

This shows the difference in length between the hydraulic roller and flat

tappets. The lifter bores in the block are the same length, but slightly

raised on the roller blocks.

This shows the difference in length between the hydraulic roller and flat

tappets. The lifter bores in the block are the same length, but slightly

raised on the roller blocks.

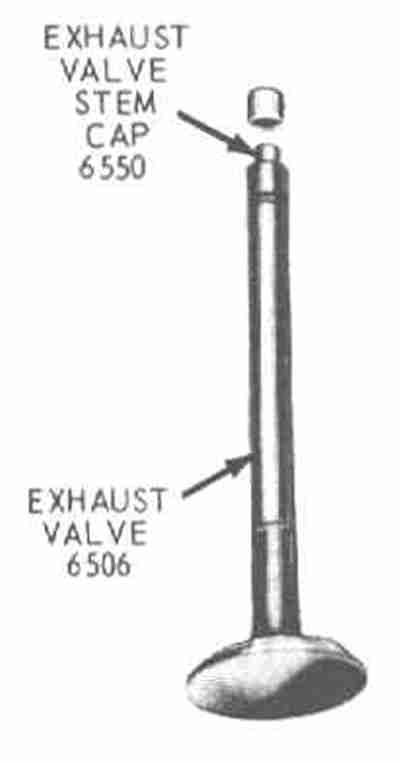

Some '70s 302s came with this type of exhaust valve. The tips are reduced in

diameter and they use hard steel lash caps. Ford had more valve stem and

pushrod lengths than you could shake a stick at, too - most of them so close

only the calipers can tell you for sure.

Some '70s 302s came with this type of exhaust valve. The tips are reduced in

diameter and they use hard steel lash caps. Ford had more valve stem and

pushrod lengths than you could shake a stick at, too - most of them so close

only the calipers can tell you for sure.

Shelby American intake with Weber carburetors. Webers were the induction

setup of choice where rules permitted.

Shelby American intake with Weber carburetors. Webers were the induction

setup of choice where rules permitted.

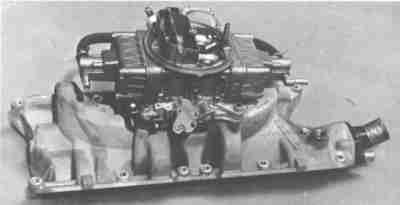

Shelby American intake and 715 CFM center-pivot Holley. This is for a GT350R

competition model. The dual plane intake helped spread out the torque curve

of the high-winding 289 engines.

Shelby American intake and 715 CFM center-pivot Holley. This is for a GT350R

competition model. The dual plane intake helped spread out the torque curve

of the high-winding 289 engines.

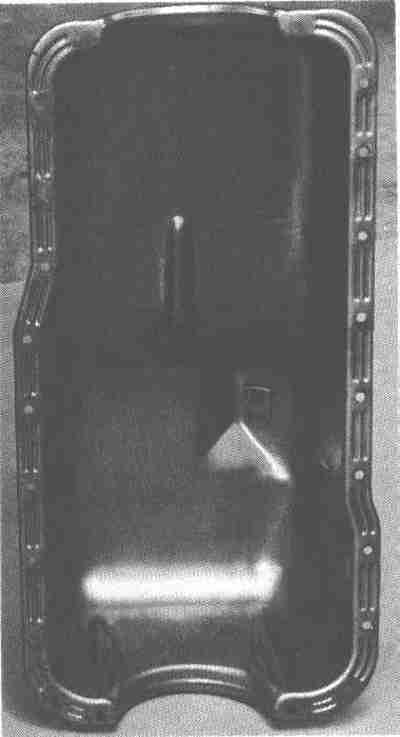

Stock 289 oil pan was an unadorned stamping, nothing to brag about. The small

block Ford was quite wide across the pan rails and the pan was relatively

deep, so the stock Ford pans actually worked better than baffled pans on, say,

Brand C engines.

Stock 289 oil pan was an unadorned stamping, nothing to brag about. The small

block Ford was quite wide across the pan rails and the pan was relatively

deep, so the stock Ford pans actually worked better than baffled pans on, say,

Brand C engines.

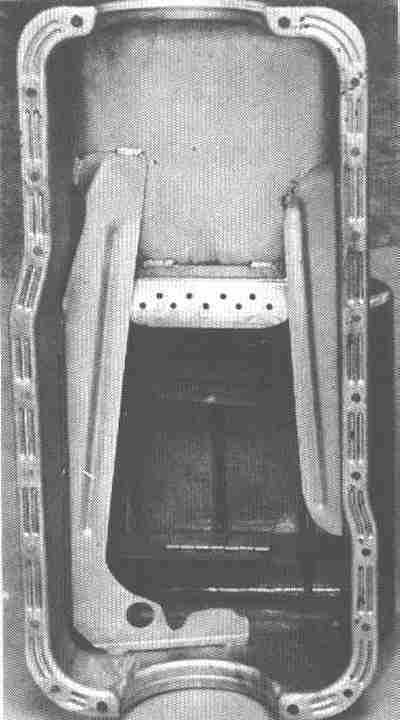

Competition Cobra pan with internal baffles. This part was also available

from Ford's parts department.

Competition Cobra pan with internal baffles. This part was also available

from Ford's parts department.

Shelby cast aluminum oil pan on Mustang Cobra. The cast pans weren't as light

as the fabricated steel pans on the early AC Cobras, but they were cheaper and

they looked great.

Shelby cast aluminum oil pan on Mustang Cobra. The cast pans weren't as light

as the fabricated steel pans on the early AC Cobras, but they were cheaper and

they looked great.

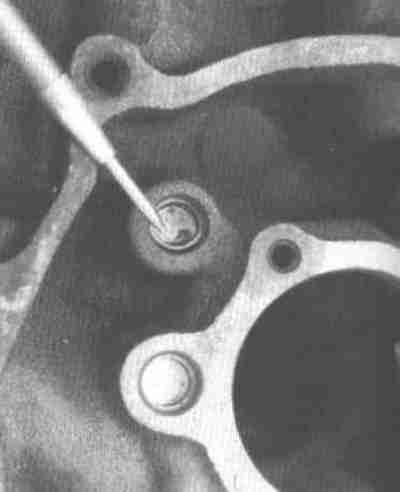

221-302 and 5.0 engines usually have pressed-in cup plugs sealing the oil

galleries. 351W engines sometimes have screw-in plugs. Though the cup plugs

seem to be reliable enough in service, most racers drill and tap the block for

1/4 NPT pipe plugs. The plug below the one indicated with the pick is the

main oil gallery. Some cam retainer plates cover this plug to ensure it can't

come out.

221-302 and 5.0 engines usually have pressed-in cup plugs sealing the oil

galleries. 351W engines sometimes have screw-in plugs. Though the cup plugs

seem to be reliable enough in service, most racers drill and tap the block for

1/4 NPT pipe plugs. The plug below the one indicated with the pick is the

main oil gallery. Some cam retainer plates cover this plug to ensure it can't

come out.

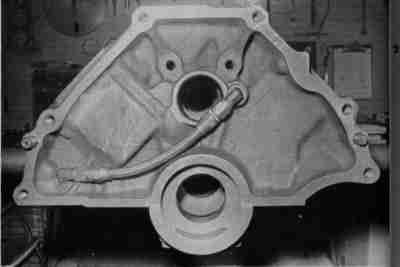

Racing modification feeds return oil from oil cooler or dry sump to both ends

of the main oil gallery to equalize pressure throughout the system.

Racing modification feeds return oil from oil cooler or dry sump to both ends

of the main oil gallery to equalize pressure throughout the system.

The small block Fords (both Windsor and Cleveland) pull the cam gear down

against the block, as opposed to pushing it up against the distributor housing

like a small block Chevy. If you insert the distributor and move the shaft up

and down, clearance should be on the order of .020". Adjusting the clearance

requires driving out the roll pin, moving the gear to the correct position,

and drilling a new hole through the distributor shaft.

The small block Fords (both Windsor and Cleveland) pull the cam gear down

against the block, as opposed to pushing it up against the distributor housing

like a small block Chevy. If you insert the distributor and move the shaft up

and down, clearance should be on the order of .020". Adjusting the clearance

requires driving out the roll pin, moving the gear to the correct position,

and drilling a new hole through the distributor shaft.

If the wear surface on the block has been damaged you'd normally throw the block away. If it's a rare or expensive block you can re-cut the surface by making an arbor to hold a valve spring seat cutter of the correct size. Then you can use a Chevy distributor shim as a spacer. You'll have to open the ID of the shim up slightly to fit the Ford shaft.

The small hole to the right of the pencil is an oil passage leading to the lower distributor shaft. Early Windsors used a groove in the cam retainer plate that led drain oil from the front cam bearing down to the oilway. Later engines use a cam bearing with a short groove leading to a second drilling that intersects this one, or (in a Cleveland) the drilling is angled.

The distributor gear is lubed by oil slung off the #1 crank throw and by oil

drainback from the left front head, just outside the picture to the right.

Some racers drill a small hole in the driver's side lifter gallery plug which

shoots some oil in the general vicinity, but it would normally go right past

the side of the distributor shaft and onto the timing chain.

Roller cam 5.0s have a longer shaft than the earlier engines. The early shaft

is long enough to go completely through the block; Ford apparently lengthened

the shaft to get a longer hex inside to hold the oil pump drive rod. Wear in

the hex was a common problem in older engines. However, if you want to use a

large diameter oil pump drive shaft you will have to shorten the shaft. You

can do it with a hacksaw if you have to; it doesn't have to be super-precise,

just short enough to clear the shoulder on the big shaft.

Roller cam 5.0s have a longer shaft than the earlier engines. The early shaft

is long enough to go completely through the block; Ford apparently lengthened

the shaft to get a longer hex inside to hold the oil pump drive rod. Wear in

the hex was a common problem in older engines. However, if you want to use a

large diameter oil pump drive shaft you will have to shorten the shaft. You

can do it with a hacksaw if you have to; it doesn't have to be super-precise,

just short enough to clear the shoulder on the big shaft.

This wintage tray is made by MPG Head Service in Colorado. It's available

from them, various vendors, and through Ford Motorsport with a Ford part

number. I've used one of these before. It's a pretty decent piece, sort of a

combination scraper/tray. It's adjustable left to right to set the scraper as

close as possible to the crank. The one I used fit fine on a 375 Windsor

stroker. MPG also makes them for the 302.

This wintage tray is made by MPG Head Service in Colorado. It's available

from them, various vendors, and through Ford Motorsport with a Ford part

number. I've used one of these before. It's a pretty decent piece, sort of a

combination scraper/tray. It's adjustable left to right to set the scraper as

close as possible to the crank. The one I used fit fine on a 375 Windsor

stroker. MPG also makes them for the 302.

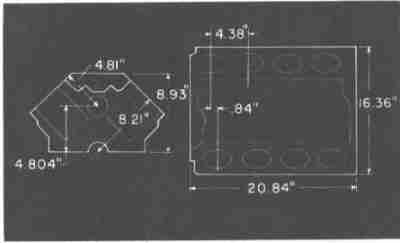

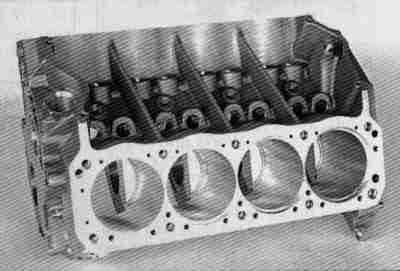

Basic block dimensions for the 221-302 Windsors. Small isn't it? The 4.804"

cam-to-crank centerline dimension is the same on the 351W, which can accept

strokes out to 4.2".

Basic block dimensions for the 221-302 Windsors. Small isn't it? The 4.804"

cam-to-crank centerline dimension is the same on the 351W, which can accept

strokes out to 4.2".

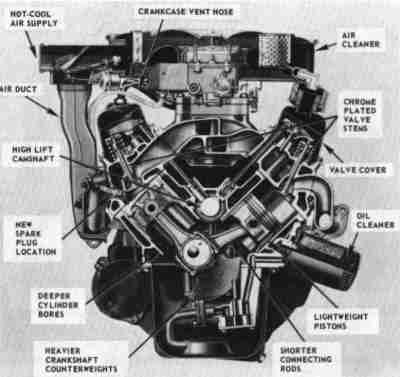

This 1968 promotional image is apparently the source of the persistent idea

that 302 blocks have deeper cylinder bores than 289 blocks. In fact, all 260-

289-302 and 5.0 bores measure out at 5-1/8". Such mismatches between iron and

documentation aren't all that unusual; the docs have to be written before the

design is finalized, and sometimes production changes creep in.

This 1968 promotional image is apparently the source of the persistent idea

that 302 blocks have deeper cylinder bores than 289 blocks. In fact, all 260-

289-302 and 5.0 bores measure out at 5-1/8". Such mismatches between iron and

documentation aren't all that unusual; the docs have to be written before the

design is finalized, and sometimes production changes creep in.

This is a '66 Shelby 289 block with the top water hole blocked off. It was

part of Shelby's modifications to the 289 HiPo; they claimed it improved the

cooling by rerouting part of the flow. Oddly enough, the holes not only came

and went at various times during 289/302/5.0 production, but they also moved

from the center to the side... and the various heads varied similarly!

This is a '66 Shelby 289 block with the top water hole blocked off. It was

part of Shelby's modifications to the 289 HiPo; they claimed it improved the

cooling by rerouting part of the flow. Oddly enough, the holes not only came

and went at various times during 289/302/5.0 production, but they also moved

from the center to the side... and the various heads varied similarly!

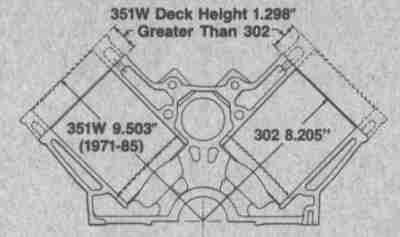

The model years stop at 1985 because this is a very old drawing. The 351W

is about 1.3 inches taller than the 302. By comparison to other American V8s,

the 302 is the shortest-deck American V8 ever produced. The 351W looks

enormous by comparison, but at 9.5 inches it's only average.

The model years stop at 1985 because this is a very old drawing. The 351W

is about 1.3 inches taller than the 302. By comparison to other American V8s,

the 302 is the shortest-deck American V8 ever produced. The 351W looks

enormous by comparison, but at 9.5 inches it's only average.

This is a 221 block. Note the mystery boss at the right rear.

This is a 221 block. Note the mystery boss at the right rear.

This is the yoke style motor mount you'll find on '60s and '70s Fords. Some

later cars wrapped a metal housing all the way around the rubber to keep the

engine from flopping around if the rubber separated, which was a fairly common

failure mode. Since the lower half of the mount could pivot around the frame

bracket bolt the rubber was sometimes loaded in shear instead of plain tension

and compression. Trucks usually used a stud and plate instead of a yoke.

This is the yoke style motor mount you'll find on '60s and '70s Fords. Some

later cars wrapped a metal housing all the way around the rubber to keep the

engine from flopping around if the rubber separated, which was a fairly common

failure mode. Since the lower half of the mount could pivot around the frame

bracket bolt the rubber was sometimes loaded in shear instead of plain tension

and compression. Trucks usually used a stud and plate instead of a yoke.

A few applications used a sheet metal shield with an asbestos liner to keep

the exhaust manifolds from cooking the rubber. I always used to throw them

away; now that I know better I grab them whenever I can find them.

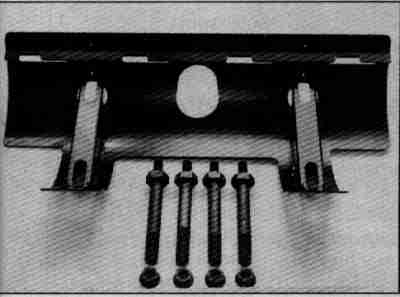

Gapp & Roush used to recommend and sell these main cap support straps. They

were once popular for all engines, not just Fords. Apparently they've gone

out of fashion now.

Gapp & Roush used to recommend and sell these main cap support straps. They

were once popular for all engines, not just Fords. Apparently they've gone

out of fashion now.

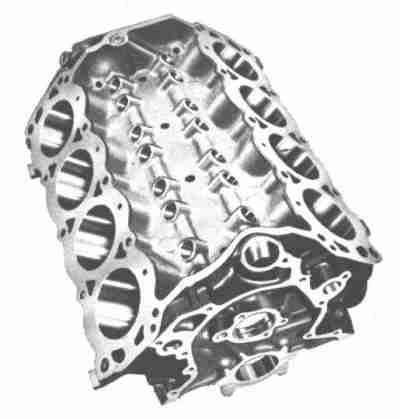

Really lousy image of a Ford Motorsport A4 block, part number M-6010-A4. They

come .017 undersize so you can finish the bores the way you want. Trendy

splayed-bolt main caps are only used on the middle three positions. #1 and #5

not only aren't four bolt, they're plain old 302 caps, not even HP289 or

Mexican 302 style. There is more meat in the cylinder walls, main webs, and

it's filled in along the pan rail. Various sources report the A4 is about 40

pounds heavier than a standard 302 block; that'd make it right around 175

pounds - the same weight as a standard 351C, 351W, or 390 FE (yes!) block.

Frankly, unless you're determined to build an 8.2" deck height 302, you'd

probably be better off starting with a 351.

Really lousy image of a Ford Motorsport A4 block, part number M-6010-A4. They

come .017 undersize so you can finish the bores the way you want. Trendy

splayed-bolt main caps are only used on the middle three positions. #1 and #5

not only aren't four bolt, they're plain old 302 caps, not even HP289 or

Mexican 302 style. There is more meat in the cylinder walls, main webs, and

it's filled in along the pan rail. Various sources report the A4 is about 40

pounds heavier than a standard 302 block; that'd make it right around 175

pounds - the same weight as a standard 351C, 351W, or 390 FE (yes!) block.

Frankly, unless you're determined to build an 8.2" deck height 302, you'd

probably be better off starting with a 351.

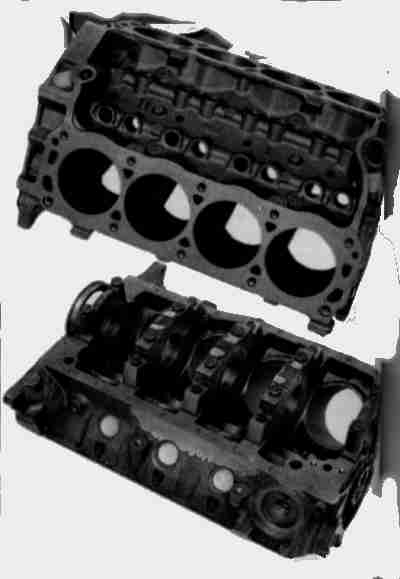

Fontana aluminum "Clevor" block. I hate the word; it sounds like the name of

some hillbilly with overalls and no teeth. Fontana has made these for almost

20 years in various configurations. If you find a used one, double check the

main bearing size and deck height, and you'll need the special Fontana timing

chain cover. If you want a new one they're still available. Price? "If you

have to ask, you probably can't afford it," as JP Morgan reputedly said.

Fontana aluminum "Clevor" block. I hate the word; it sounds like the name of

some hillbilly with overalls and no teeth. Fontana has made these for almost

20 years in various configurations. If you find a used one, double check the

main bearing size and deck height, and you'll need the special Fontana timing

chain cover. If you want a new one they're still available. Price? "If you

have to ask, you probably can't afford it," as JP Morgan reputedly said.

Ah, a better shot of a Fontana block. This one takes a Cleveland cam and

crank.

Ah, a better shot of a Fontana block. This one takes a Cleveland cam and

crank.

To take the Cleveland cam you need to offset the oil pump .150" outboard. And

you might as well make the pan rails Cleveland-style... the Fontana is really

more of a Cleveland than a Windsor. Four bolt mains on all five caps.

To take the Cleveland cam you need to offset the oil pump .150" outboard. And

you might as well make the pan rails Cleveland-style... the Fontana is really

more of a Cleveland than a Windsor. Four bolt mains on all five caps.

Nowak stud girdle. This is fairly representative of the 'thin' type girdles

from several manufacturers. Most of them bolt on with no machine work. They

can't hurt, but I don't feel the Windsors have a main cap problem to start

with. By the time you rattle the caps with a blower or nitrous, you're out of

stock block territory anyway.

Nowak stud girdle. This is fairly representative of the 'thin' type girdles

from several manufacturers. Most of them bolt on with no machine work. They

can't hurt, but I don't feel the Windsors have a main cap problem to start

with. By the time you rattle the caps with a blower or nitrous, you're out of

stock block territory anyway.

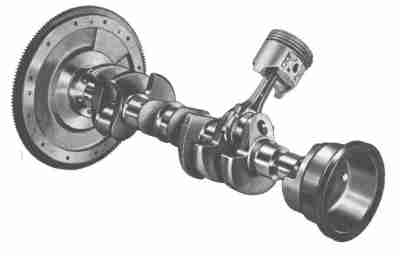

This is a Ford airbrush drawing of a generic Windsor rotating assembly, circa

1964. It has a 289 HiPo harmonic balancer but no add-on bob weight. The

flywheel and balancer clearly show the additional 28.2 oz of weight added to

balance the engine. The weight is not split evenly on the ends; more is on

the front than the back, about 70/30. A 5.0 with the 50oz flywheel has a

weight almost twice as wide, and the harmonic balancer counterweight covers

fully half its diameter instead of being a simple wedge.

This is a Ford airbrush drawing of a generic Windsor rotating assembly, circa

1964. It has a 289 HiPo harmonic balancer but no add-on bob weight. The

flywheel and balancer clearly show the additional 28.2 oz of weight added to

balance the engine. The weight is not split evenly on the ends; more is on

the front than the back, about 70/30. A 5.0 with the 50oz flywheel has a

weight almost twice as wide, and the harmonic balancer counterweight covers

fully half its diameter instead of being a simple wedge.

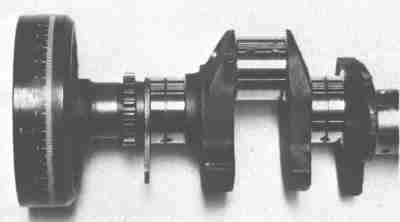

This crank is from a '65 Shelby 289 competition engine. Note the grooved main

journals, 289 HP extra bobweight, and the fully-degreed harmonic balancer.

All these items were available individually from Shelby. Later engines

used grooved bearings instead of grooving the crankshaft.

This crank is from a '65 Shelby 289 competition engine. Note the grooved main

journals, 289 HP extra bobweight, and the fully-degreed harmonic balancer.

All these items were available individually from Shelby. Later engines

used grooved bearings instead of grooving the crankshaft.

This shot gives you a good idea of how long the snout is on the small block

crank, and how much leverage the harmonic balancer and pulleys have across the

#1 main. It's not a problem with 289 and 302 cranks, but the lightweight 50-

oz. imbalanced 5.0 cranks break regularly just in front of the first rod throw

when run even for moderate times at high RPM, such as SCCA A-Sedan racing.

This particular crank is from a 1969 DeTomaso Mangusta with a 302.

This shot gives you a good idea of how long the snout is on the small block

crank, and how much leverage the harmonic balancer and pulleys have across the

#1 main. It's not a problem with 289 and 302 cranks, but the lightweight 50-

oz. imbalanced 5.0 cranks break regularly just in front of the first rod throw

when run even for moderate times at high RPM, such as SCCA A-Sedan racing.

This particular crank is from a 1969 DeTomaso Mangusta with a 302.

Wild Herbert & Meek headers for early Pinto swap. They went out of production

around 1980, but they're still the dog's ballocks, eh wot?

Wild Herbert & Meek headers for early Pinto swap. They went out of production

around 1980, but they're still the dog's ballocks, eh wot?

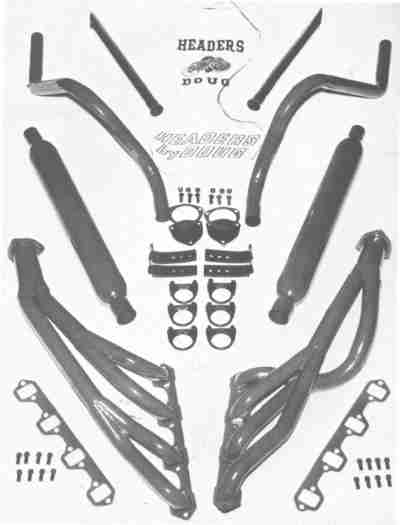

Doug Thorley tri-Y headers for early Mustangs. These are very similar to the

Shelby tri-Ys. You see lots of tri-Y headers on 289 racers. Before exotic

aftermarket heads became available the only practical way to make power was to

stuff as much compression and cam in as you could stand and spin it up just

shy of disintegration. This tended to make the 289s weak in midrange. The

tri-Ys perked up midrange without losing much from the top end.

Doug Thorley tri-Y headers for early Mustangs. These are very similar to the

Shelby tri-Ys. You see lots of tri-Y headers on 289 racers. Before exotic

aftermarket heads became available the only practical way to make power was to

stuff as much compression and cam in as you could stand and spin it up just

shy of disintegration. This tended to make the 289s weak in midrange. The

tri-Ys perked up midrange without losing much from the top end.

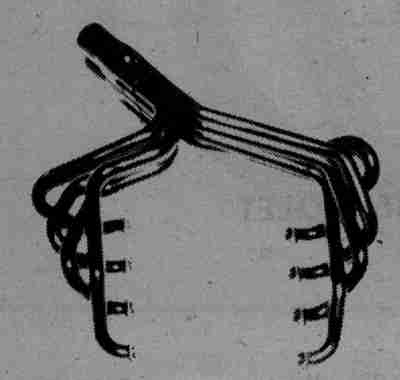

Schoenfeld made these 180 degree headers circa 1983. They cost $159.95 back

then.

Schoenfeld made these 180 degree headers circa 1983. They cost $159.95 back

then.

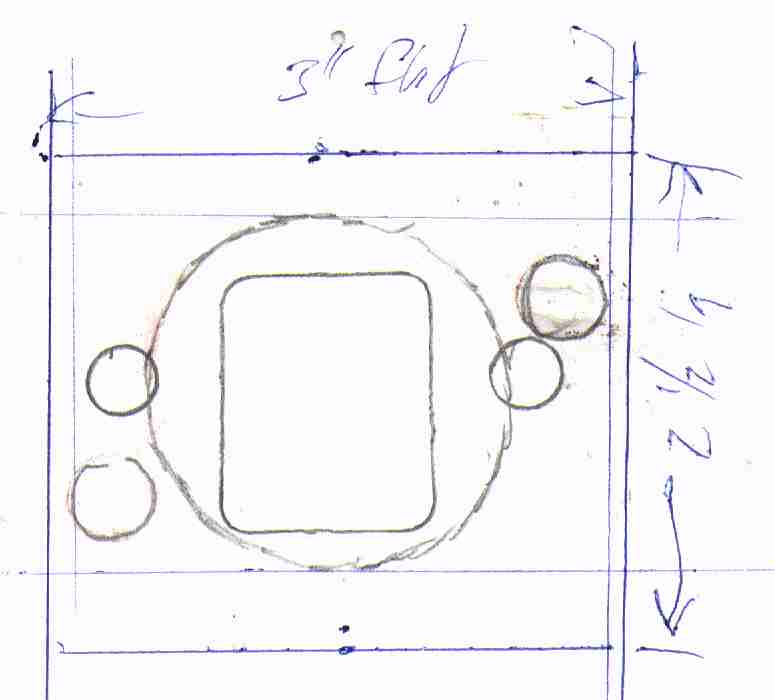

This drawing was made while building a pair of adapters to fit a pair of

Motorsport diagonal-pattern racing headers to a pair of factory 289 heads.

The threads in the diagonal pattern went through the edge of the right hand

countersunk screw.

This drawing was made while building a pair of adapters to fit a pair of

Motorsport diagonal-pattern racing headers to a pair of factory 289 heads.

The threads in the diagonal pattern went through the edge of the right hand

countersunk screw.

Shelby GT350 with optional Paxton supercharger. Some cars were delivered with

the supercharger as a factory-installed option. Shelby American also marketed

the kits directly and through some Ford dealerships.

Shelby GT350 with optional Paxton supercharger. Some cars were delivered with

the supercharger as a factory-installed option. Shelby American also marketed

the kits directly and through some Ford dealerships.