Author: Dave Williams; dlwilliams=aristotle=net

All of the cylinder head work, final assembly, and dozens of other pictures were lost, so I'll try to add some extra commentary to some redundant pictures.

John Miller wanted a stroker motor for his Taurus SHO. He's in California,

made a deal on an engine in Ohio, and used the Fangle Express to get it to

Arkansas.

John Miller wanted a stroker motor for his Taurus SHO. He's in California,

made a deal on an engine in Ohio, and used the Fangle Express to get it to

Arkansas.

Bruce Plecan showed up one winter afternoon with the SHO, which he'd picked up near his house in Ohio, 3.8 and 4.1 Buick V6 engines for his car, a Maserati Biturbo he picked up for me in Indiana, and an aluminum 351 Cleveland he picked up in St. Louis. That's the Fangle Express!

The tiny size automatic transmission flexplate is an illusion. The SHO is

ENORMOUS.

Firewall side. The crank pulley and sprocket were missing, but someone had

left the belt.

Firewall side. The crank pulley and sprocket were missing, but someone had

left the belt.

Starting disassembly - pulling the box-of-snakes intake.

Starting disassembly - pulling the box-of-snakes intake.

Back side. The aluminum cover is a combination rear main seal and crankcase

vent; it connects the center valley to the crankcase. The flanges on the oil

pan are for additional braces to the bellhousing.

Back side. The aluminum cover is a combination rear main seal and crankcase

vent; it connects the center valley to the crankcase. The flanges on the oil

pan are for additional braces to the bellhousing.

SHO adjacent to a small block Chevy. Yes, it's taller and wider, just not

quite as long. The bulky intake manifold has already been removed from the

SHO.

SHO adjacent to a small block Chevy. Yes, it's taller and wider, just not

quite as long. The bulky intake manifold has already been removed from the

SHO.

The engine had been pumping quite a bit of oil. The source wasn't

immediately obvious.

The engine had been pumping quite a bit of oil. The source wasn't

immediately obvious.

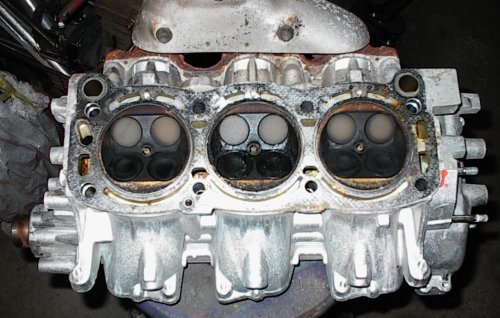

Cylinder head. It's hard to get across just how bulky and heavy it is.

"Aluminum is lighter; we must use more of it." Putting the cams upstairs also

adds weight.

Cylinder head. It's hard to get across just how bulky and heavy it is.

"Aluminum is lighter; we must use more of it." Putting the cams upstairs also

adds weight.

Crank-snout-driven oil pump, long pickup tube, slotted windage tray.

Crank-snout-driven oil pump, long pickup tube, slotted windage tray.

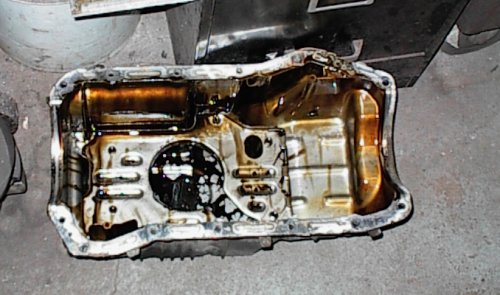

Elaborate baffling down in the cast-aluminum oil pan.

Elaborate baffling down in the cast-aluminum oil pan.

Bolt-on main girdle. The caps are also quite beefy.

Bolt-on main girdle. The caps are also quite beefy.

At least I'm down to the short block. This is the only part I care about;

John is supposed to get the stroked short block and a pallet full of parts.

At least I'm down to the short block. This is the only part I care about;

John is supposed to get the stroked short block and a pallet full of parts.

Forged steel SHO crank on the grinder, being offset ground. As is usual for

modern small engine designs, the crank is fully counterweighted.

Forged steel SHO crank on the grinder, being offset ground. As is usual for

modern small engine designs, the crank is fully counterweighted.

After grinding the crank got sent to Moldex in Michigan, for heat treat and

surface hardening.

After grinding the crank got sent to Moldex in Michigan, for heat treat and

surface hardening.

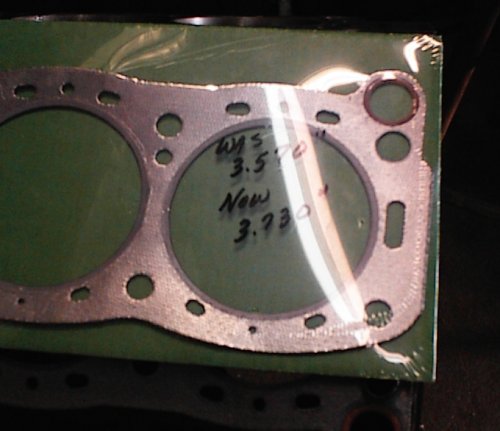

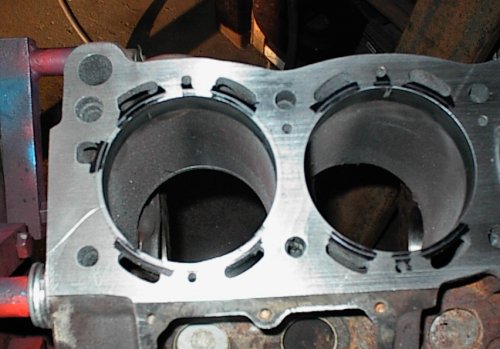

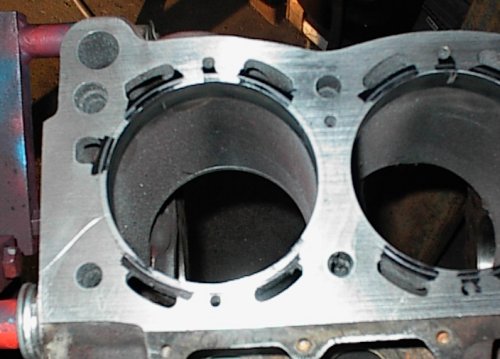

The key to the whole project - John acquired a pair of custom-made big bore

head gaskets. There were made by hand-fitting larger fire rings to opened-up

SHO replacement gaskets. The stock gaskets fit closely to the bore and don't

leave enough room for major overbore.

The key to the whole project - John acquired a pair of custom-made big bore

head gaskets. There were made by hand-fitting larger fire rings to opened-up

SHO replacement gaskets. The stock gaskets fit closely to the bore and don't

leave enough room for major overbore.

Aftermarket aluminum flywheel. It weighed something like 7 pounds. Somehow

it had been made slightly out of balance. Unfortunately, there wasn't really

any good place to add or remove metal. It was in good enough balance for most

shops, but I like to get strokers balanced down to the limits of resolution of

my machine. I center-punched some holes in the plane of imbalance.

Aftermarket aluminum flywheel. It weighed something like 7 pounds. Somehow

it had been made slightly out of balance. Unfortunately, there wasn't really

any good place to add or remove metal. It was in good enough balance for most

shops, but I like to get strokers balanced down to the limits of resolution of

my machine. I center-punched some holes in the plane of imbalance.

One side got some holes drilled all the way through. The other got slightly

smaller holes, threaded, with short pieces of steel threaded rod Loctited in

place. It was enough to bring it into balance.

One side got some holes drilled all the way through. The other got slightly

smaller holes, threaded, with short pieces of steel threaded rod Loctited in

place. It was enough to bring it into balance.

The wheel was used, and the friction surface was pretty ugly. I resurfaced

it before balancing.

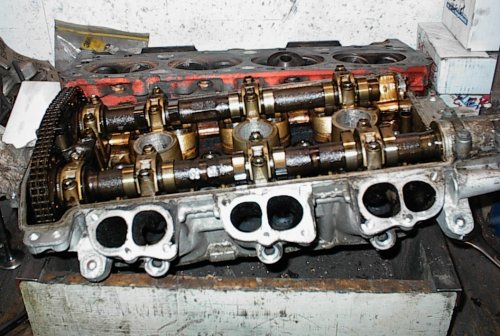

SHO cylinder head. This is what most people think of when they think

"overhead cam" - that is, bucket followers and shims. Most production cars

use rocker arms and hydraulic pivots.

SHO cylinder head. This is what most people think of when they think

"overhead cam" - that is, bucket followers and shims. Most production cars

use rocker arms and hydraulic pivots.

Part of the SHO's elaborate cam drive. This chain connects the two cams,

which are driven from the other end of the left cam, out of the picture. The

connecting chain has an oil-pressure-actuated tensioner and nylon shoes top

and bottom. The bits were all worn, and John sourced some replacements.

Part of the SHO's elaborate cam drive. This chain connects the two cams,

which are driven from the other end of the left cam, out of the picture. The

connecting chain has an oil-pressure-actuated tensioner and nylon shoes top

and bottom. The bits were all worn, and John sourced some replacements.

Manley Tour Lite rods, "Honda journal" small block Chevy. This was the first

time I'd used the "Honda" rods. Yes, the bearings are the same size as a

Honda, but they're not Honda bearings - they're wider and have the tangs in a

different place. The single source is Clevite, and they're only available in

sets of eight pair, for $125. That's 10x the price of a regular V8 set.

Manley Tour Lite rods, "Honda journal" small block Chevy. This was the first

time I'd used the "Honda" rods. Yes, the bearings are the same size as a

Honda, but they're not Honda bearings - they're wider and have the tangs in a

different place. The single source is Clevite, and they're only available in

sets of eight pair, for $125. That's 10x the price of a regular V8 set.

Back of the block during final cleaning. Mr. Wire Wheel cleaned up

Yankeeland rust that had grown during the engine's first life. Note the vent

holes in the rear main web. The vent holes to the valley are at the top of

the cavity, not visible in this shot.

Back of the block during final cleaning. Mr. Wire Wheel cleaned up

Yankeeland rust that had grown during the engine's first life. Note the vent

holes in the rear main web. The vent holes to the valley are at the top of

the cavity, not visible in this shot.

Fresh from the crank grinder. The mains

Fresh from the crank grinder. The mains

Since the porter had changed the valve heights slightly and the cams were reground, I needed quite a few new adjustment shims to get the clearances right. John sent a big bad of NOS Ford shims.

The Fangle Express got the engine from here to San Franciso. Norm swung by on his way from Ohio to SF and dropped the engine to John's house!