Author: Dave Williams; dlwilliams=aristotle=net

The 350 in Felix's Suburban was getting a bit elderly, so we decided to build a fresh engine for it. Since cost was a major factor, we re-used whatever we could find that was still good. We're closing in on 50,000 miles later, and it's still running strong...

May 2005: Make that 90,000 miles...

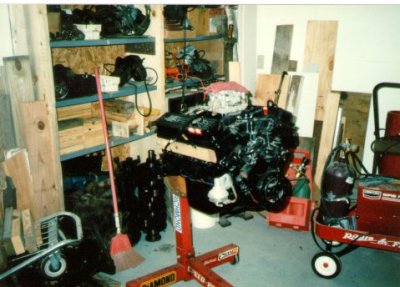

We started with this Mercury Marine 350. It had only a hundred or so hours on

it when the owner let it freeze over the winter of 1987. Both the block and

heads were cracked. I sleeved one cylinder and welded a crack across the

deck, pressure checked, and the block still looked like a fountain. I tossed

it and scrounged a 1997 block in perfect shape. The heads were cracked, so I

replaced them with some early heavy truck castings.

We started with this Mercury Marine 350. It had only a hundred or so hours on

it when the owner let it freeze over the winter of 1987. Both the block and

heads were cracked. I sleeved one cylinder and welded a crack across the

deck, pressure checked, and the block still looked like a fountain. I tossed

it and scrounged a 1997 block in perfect shape. The heads were cracked, so I

replaced them with some early heavy truck castings.

I guess that's sort of like George Washington's axe (handle replaced five

times, head twice), but it started as a Mercury Marine 350 when I

started working on it...

Bronze guide liners were installed first, then I ground the seats.

These heads came from a school bus. They're essentially small

port, large chamber 307 castings. They have real "hard" seats - inserted

carbide, harder than the clappers of Hell. The seats were also quite small,

bearing on the very inside edges of the valves. I wanted to improve flow a

bit, so I opened them up to seat on the outside edges of the valves. This

took many hours and ruined many stones.

Bronze guide liners were installed first, then I ground the seats.

These heads came from a school bus. They're essentially small

port, large chamber 307 castings. They have real "hard" seats - inserted

carbide, harder than the clappers of Hell. The seats were also quite small,

bearing on the very inside edges of the valves. I wanted to improve flow a

bit, so I opened them up to seat on the outside edges of the valves. This

took many hours and ruined many stones.

I found out that truck heads have 7/16" accessory bolt holes instead of 3/8"! I wound up having to go over to Felix's and Heli-Coil the alternator and air conditioner bolt holes... then we found out the passenger side bolt holes aren't *quite* in the same place as the car/light truck heads! So I wound up making a new alternator bracket with the welder. So much for the vaunted Chevy parts interchangeability...

Valve sizes are 1.72/1.50. I back-cut all the valves, made a 20 degree cut on the intake faces, and radiused the exhaust faces. The exhaust stem diameter is 3/8", typical for heavy duty trucks, and there are Stellite caps on the tips. I retained the rotators on the exhaust valves.

The small ports and valves keep intake velocity up for good mileage and

throttle response on heavy trucks. It also works for 5600 pound Suburbans...

The head bits laid out for assembly. By the time you add retainers, keepers,

and seals, there are quite a few parts there.

The head bits laid out for assembly. By the time you add retainers, keepers,

and seals, there are quite a few parts there.

Stock Mercury Marine windage tray. Same for the single-row roller timing

chain hidden by the plastic '97 timing cover. The covers are non-reuseable

and cost $35 at the dealer. I had to make an aluminum plug to go in the hole

where the stock crank position sensor went.

Stock Mercury Marine windage tray. Same for the single-row roller timing

chain hidden by the plastic '97 timing cover. The covers are non-reuseable

and cost $35 at the dealer. I had to make an aluminum plug to go in the hole

where the stock crank position sensor went.

The Mercury Marine 6-quart oil pan fit the Suburban chassis fine. It has

caused Felix no end of hassle with quick-lube places that dump in 5 quarts and

refuse to pull the stick to check, though.

Since it was apart, I weighed all the bits - they were identical - built the balance weights, and spun it up. It was dead smooth. No Chevy car engine I've ever checked has even been *close* to this. I figure the balance is one of the differences between a car engine and a marine engine - marine engines are usually mounted solid, and any vibration would be transmitted through the hull.

I rebuilt the HEI and added an Accel HEI Super Coil. Felix popped for a set of 1.6:1 aluminum roller rockers and had a local shop rebuild the Quadrajet. We found out his Suburban used a 7-hole exhaust manifold on the passenger side and the truck heads had only six holes, so I scrounged a 6-hole manifold and Felix had the pipes tweaked by a muffler shop so everything fit.

Since all this, Felix has bought a Painless Wiring TBI harness, a '7747 computer with the correct chip, a 350 throttle body, the correct vehicle speed sensor for the transmission, and so forth. We have the wiring harness installed, and when the round tuits line up we'll try firing up the EFI.

Here's the TBI adapter. They were used on EFI-equipped GMC 366 tall-deck

truck engines. GM apparently didn't want to cast up a special wide truck-

block TBI intake, so they made these adapters.

Here's the TBI adapter. They were used on EFI-equipped GMC 366 tall-deck

truck engines. GM apparently didn't want to cast up a special wide truck-

block TBI intake, so they made these adapters.

The adapters are hollow, with fittings to run coolant lines through. This

helps promote vaporization of the fuel. The swirling ridges are supposed to

help air/fuel distribution. These might not be quite as good as a real TBI

intake, but it'll be easy to swap the carb off and TBI on to experiment. If

we can't get it started, it'll be easy enough to swap it back to the carb.

The adapters are hollow, with fittings to run coolant lines through. This

helps promote vaporization of the fuel. The swirling ridges are supposed to

help air/fuel distribution. These might not be quite as good as a real TBI

intake, but it'll be easy to swap the carb off and TBI on to experiment. If

we can't get it started, it'll be easy enough to swap it back to the carb.

And here's the next step - a perfectly ordinary right-side Suburban exhaust

manifold...

And here's the next step - a perfectly ordinary right-side Suburban exhaust

manifold...

...which ought to make a dandy manifold for a single-turbo application. The

exhaust ports turn straight up into the manifold; they aren't angled back

toward the back at all. So we can route a crossover pipe into the pack and

exhaust out the front with no problem at all.

...which ought to make a dandy manifold for a single-turbo application. The

exhaust ports turn straight up into the manifold; they aren't angled back

toward the back at all. So we can route a crossover pipe into the pack and

exhaust out the front with no problem at all.

Some angle grinder work, and we have a nice port, ready for a short

trapezoidal box structure of 1/8" and 3/8" steel plate to be welded on. We

can't go any further until Felix actually gets the turbo in hand, so we can

position the outlet correctly. He's looking for a GM 6.5 or Ford Powerstroke

turbo.

Some angle grinder work, and we have a nice port, ready for a short

trapezoidal box structure of 1/8" and 3/8" steel plate to be welded on. We

can't go any further until Felix actually gets the turbo in hand, so we can

position the outlet correctly. He's looking for a GM 6.5 or Ford Powerstroke

turbo.