The 456 uses a heavy-duty FT block and a spare 428 crank Dan happened to have on hand. Slant Six connecting rods were originally supposed to carry cast Chevy rebuilder pistons, but Dan decided to go for custom Venolia forgings, which also let him drop the compression ratio closer to 10:1.

Stripping an old Chrysler Slant Six for its connecting rods. I found two more

at a buddy's engine shop to make eight. Then I had to find a place to dispose

of a defunct Slant Six...

Stripping an old Chrysler Slant Six for its connecting rods. I found two more

at a buddy's engine shop to make eight. Then I had to find a place to dispose

of a defunct Slant Six...

Narrowing a Slant Six rod in my fancy rod fixture. You have to take almost

half an inch off!

Narrowing a Slant Six rod in my fancy rod fixture. You have to take almost

half an inch off!

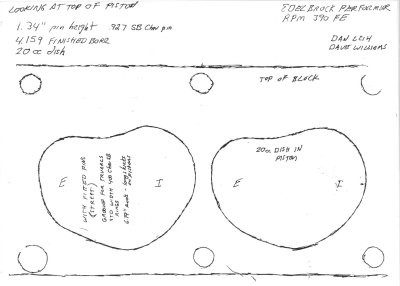

Mirror tracing of combustion chamber for the Edelbrock heads, ready to fax to

Venolia. They made up a set of customs.

Mirror tracing of combustion chamber for the Edelbrock heads, ready to fax to

Venolia. They made up a set of customs.

Pistons taped up for sandblasting.

Pistons taped up for sandblasting.

$750 worth of bright, machined aluminum reduced to corncob roughness...

$750 worth of bright, machined aluminum reduced to corncob roughness...

Cleaned, retaped, ready to shoot with CBC2 ceramic thermal barrier coating.

Cleaned, retaped, ready to shoot with CBC2 ceramic thermal barrier coating.

Just shot the coating; still wet. Skirts are masked off.

Just shot the coating; still wet. Skirts are masked off.

Now shooting the skirts with TLML moly.

Now shooting the skirts with TLML moly.

...and now we bake for an hour at 350F...

...and now we bake for an hour at 350F...

Baked, detaped, polished, and washed. Next we hang them on the rods.

Baked, detaped, polished, and washed. Next we hang them on the rods.

Rod heater warming the pin ends so we can slide the pins through...

Rod heater warming the pin ends so we can slide the pins through...

...fixture so they get lined up correctly.

...fixture so they get lined up correctly.

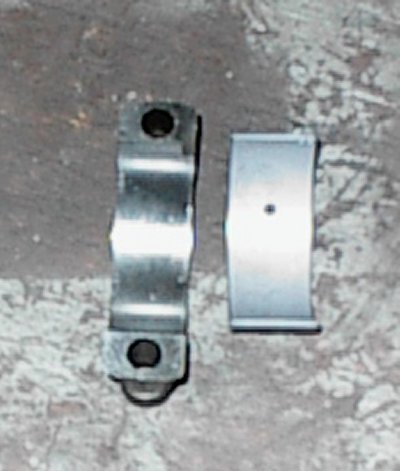

The Slant Six rods are now much narrower than their bearings. The bearings,

purchased new in 2001, were in crumbly old TRW boxes and had a manufacturing

date of 1977.

The Slant Six rods are now much narrower than their bearings. The bearings,

purchased new in 2001, were in crumbly old TRW boxes and had a manufacturing

date of 1977.

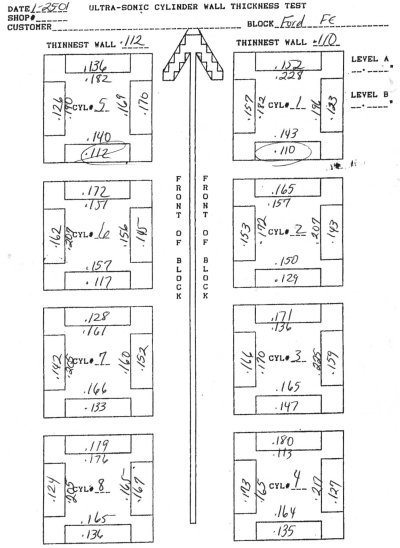

Sonic check chart. There's only one place in the whole state that'll do it,

but they do a pretty good job. The bore was already 4.09", but there was

plenty of meat by FE standards.

Sonic check chart. There's only one place in the whole state that'll do it,

but they do a pretty good job. The bore was already 4.09", but there was

plenty of meat by FE standards.

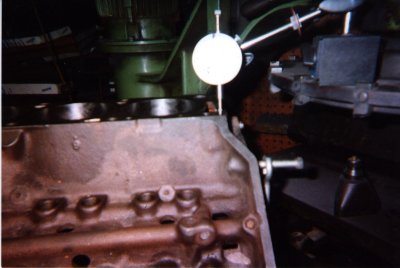

The short block had come from a junkyard. It'd seen a hard life before being

kicked around in the core pile. The decks were somewhat beaten up. I hemmed

and hawed for a while, because it was one of those judgement calls it's hard

to be sure about. If it had been a stock rebuild I would probably have let it

go. For a big stroker... I hauled the block over to a buddy's shop to be

decked. John Crowder at Motor Pro dropped everything to rush it through; he

even took pictures. Here, he's setting up the block in his his Storm Vulcan

surfacing machine.

The short block had come from a junkyard. It'd seen a hard life before being

kicked around in the core pile. The decks were somewhat beaten up. I hemmed

and hawed for a while, because it was one of those judgement calls it's hard

to be sure about. If it had been a stock rebuild I would probably have let it

go. For a big stroker... I hauled the block over to a buddy's shop to be

decked. John Crowder at Motor Pro dropped everything to rush it through; he

even took pictures. Here, he's setting up the block in his his Storm Vulcan

surfacing machine.

Making the first pass. Since we had to cut it anyway, John squared the decks

end to end and side to side, and to zero the deck height so the pistons got

maximum quench.

Making the first pass. Since we had to cut it anyway, John squared the decks

end to end and side to side, and to zero the deck height so the pistons got

maximum quench.

You can see a few wavy spots that aren't quite cleared up on this first pass.

The second pass, everything was fine.

You can see a few wavy spots that aren't quite cleared up on this first pass.

The second pass, everything was fine.

Block back from being align bored. $100 poorer, but at least the crank turns

now... Sending the block out twice for outside work hammered the budget

somewhat, but sometimes there's no other way.

Block back from being align bored. $100 poorer, but at least the crank turns

now... Sending the block out twice for outside work hammered the budget

somewhat, but sometimes there's no other way.

The front main oil hole has been beveled to line up with the bearing

shell. The others lined up fine. Not all FEs do.

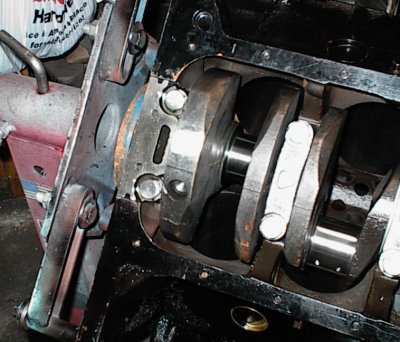

Bearings and rear seal in place, ready to drop the crank in. It'll get

Plastigaged again, just to make sure everything is straight. The inside and

outside mikes will tell you if the main bores and crank journals are

round, but they can't tell you if they're in alignment.

Bearings and rear seal in place, ready to drop the crank in. It'll get

Plastigaged again, just to make sure everything is straight. The inside and

outside mikes will tell you if the main bores and crank journals are

round, but they can't tell you if they're in alignment.

Crank in and torqued. Finally! Everything correct, aligned, and spinning

freely.

Crank in and torqued. Finally! Everything correct, aligned, and spinning

freely.

This is all the drilling it took to balance the front end.

This is all the drilling it took to balance the front end.

And here is the back. Stock FE rods and pistons are very heavy; strokers

usually don't need any heavy metal, which greatly simplifies things.

And here is the back. Stock FE rods and pistons are very heavy; strokers

usually don't need any heavy metal, which greatly simplifies things.

Gapping the rings. I wound up mixing .030 and .040-oversize 400 Chevy rings

to adjust the end gaps to something more my liking. Stock replacement rings

usually have much wider gaps than the specs call for, probably so ham-handed

rebuilders can't screw things up. I like to run closer to the tight side of

the clearance spec when I can.

Gapping the rings. I wound up mixing .030 and .040-oversize 400 Chevy rings

to adjust the end gaps to something more my liking. Stock replacement rings

usually have much wider gaps than the specs call for, probably so ham-handed

rebuilders can't screw things up. I like to run closer to the tight side of

the clearance spec when I can.

Board keeps the rings separated and in order for assembly onto the pistons.

Board keeps the rings separated and in order for assembly onto the pistons.

Custom Cam Research flat tappet cam. Dan paid extra to have them run it in on

their break-in machine; you can see the marks in the phosphate coating.

Custom Cam Research flat tappet cam. Dan paid extra to have them run it in on

their break-in machine; you can see the marks in the phosphate coating.

In this shot you can see the short fill of Hard Block concrete filler. This

block wasn't that thin for an FE, but it's better safe than sorry.

In this shot you can see the short fill of Hard Block concrete filler. This

block wasn't that thin for an FE, but it's better safe than sorry.

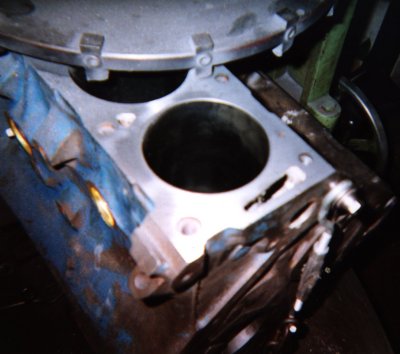

#5 cylinder was munged, so I bored it out and pressed in a sleeve. The

groove you see is from the chamfer at the bottom of the bored hole in the

block and the chamfer at the bottom of the sleeve. It's harmless; only the

skirt rides down there.

#5 cylinder was munged, so I bored it out and pressed in a sleeve. The

groove you see is from the chamfer at the bottom of the bored hole in the

block and the chamfer at the bottom of the sleeve. It's harmless; only the

skirt rides down there.

I didn't have the engine finished in time for Dan to take it home when he

swung by on vacation, so I crated it up for shipment.

I didn't have the engine finished in time for Dan to take it home when he

swung by on vacation, so I crated it up for shipment.

I built the crate on an ordinary shipping pallet. I'm getting ready to screw

the lid on now.

I built the crate on an ordinary shipping pallet. I'm getting ready to screw

the lid on now.

=============================================================================

M A X I M U M O V E R D R I V E R A C I N G E N G I N E S

PO Box 181, Jacksonville, AR 72078-0181

=============================================================================

456 FE stroker for Dan Leih, Chandler AZ

completed May 2002 (long block)

4.155 x 4.20 456 CID - 7467cc

10.17 FE deck

2.100 half of 4.200 stroke

6.69 /6 rod

------

1.38" piston pin height

4.155 x 4.20 = 933cc/cyl

75 cc Edelbrock Performer heads

8.25 cc Dana 3389 head gasket (.035")

20 cc piston dish

-----

103.25 clearance volume

933 / 103.25 = 9.0:1 compression ratio

warranty: if it breaks, you get to keep all the pieces you can find

COMPONENTS ---------------------------------------------------------------

heads:

Edelbrock Performer aluminum

checked 75cc with buret

block:

Ford FT 361 casting "reverse 105" marking

sonic checked

caustic dipped

all threaded holes chased

new freeze plugs

decked flat

align honed mains

bored to 4.155"

honed to #400 finish

ground main bearing oil passages over to match bearings

drilled out all the pressed/ground off/stripped oil plugs

taper reamed and tapped oil holes 1/4 NPT

rodded out the oil passages

tapped the rocker arm oil holes in the decks 3/8-16 for screw-in

restrictors (.080", unless you want something else)

drilled oil pump hole from 3/8" to 1/2", did a bunch of radiusing

and polishing

flared the 7/16" hole from the adapter pad into the block

drilled a .060" hole from the distributor shaft oilway to the gear

thrust pad to oil the distributor gear

Hard Block filler

crankshaft:

428 Ford casting

stroked to 4.20"

Slant Six rod journal size

rod throw widths: #1 1.765"

#2 1.765"

#3 1.765"

#4 1.765"

connecting rods:

Slant Six Dodge

big ends narrowed from 1.21" to .878"

small ends opened to .925"

ARP 144-6001 rod bolts (360 V8)

stretch bolts to .0065"

resized

side clearance: #1 .007"

#2 .007"

#3 .010"

#4 .010"

narrow Slant Six rod bearings to .830", 45 deg by .050", cheek side

widen tang grooves as needed to adjust bearing locations

oil squirt holes point to camshaft

pistons:

Venolia custom forgings

CNC machined to match Edelbrock heads

20cc dish

.135" taper wall pins

5/64, 5/64, 3/16 ring grooves

.927" pins

1.38" pin height

CBC2 thermal barrier coating on tops

TLML moly antifriction coating on sides

rings:

5/64, 5/64, 3/16"

top rings .030"

oil rings .030/.040"

gaps:

#5 .020 #1 .036

.025 .029

.010/.040 .010/.045

#6 .034 #2 .032

.028 .029

.010/.045 .010/.044

#7 .028 #3 .031

.023 .028

.010/.040 .010/.044

#8 .030 #4 .031

.025 .027

.010/.040 .010/.046

balance:

neutral balance (390)

471 big end

471 big end

50 rod bearing

50 rod bearing

668 piston and pin

58 rings

197 rod reciprocating

---

1965 grams

setup RPM 800

balance RPM 650

balance .025 oz-in front, .030 oz-in rear

drill only

camshaft:

Cam Research pn CR 298 solid lifter

serial # 112823TL

233/235 @ .050, 298/302 advertised

.560/.560 lift

intake open 9 BTDC, close 44 ABDC

exhaust open 47 BBDC, close 6 ATDC

109 degree lobe center

.012/.012 lash

note:

Dana Tech Support - #3389 gasket has 4.280 bore opening

09/11/98 NAPA wants $21.49 for #3389

===========================================================================

assembly lubricants:

rod bearings: Unilube moly assembly lube

rings: Unilube two stroke oil

cylinder walls: Mobil 1 5w30

piston skirts: Mobil 1 5w30

wrist pins: Mobil 1 5w30

head bolts - threads: 30wt ND

main bolts - threads: 30wt ND

head, main bolts - under head: 30wt ND

rod bolts: ARP super moly

cam bolt: Loctite 252 Blue

cam lobes: Iskenderian moly cam lube

cam journals: 30wt ND

cam distributor drive gear: Iskenderian cam lube

crankshaft rear oil seal: Unilube assembly lube

===========================================================================

TORQUE SPECIFICATIONS -----------------------------------------------------

--------torque---------------spec-----------thread---lube------------------

rod bolts

torqued to .0065" stretch .0065-.0067 3/8-24 ARP moly lube

note: 1) step 1: 50 ft-lb (both bolts)

step 2: loosen both bolts

step 3: 50 ft-lb (both bolts)

main cap bolts

torqued to 100 ft-lb (Ford spec 95-105) oil

note: 1) use moly grease under bolt head

2) step 1: 50 ft-lb

step 2: 75 ft-lb (reverse pattern)

step 3: 100 ft-lb

head bolts

(Ford spec 80-90) oil

note: 1) use moly grease under bolt head

2) block is blind tapped, no sealer needed

3) step 1: 50 ft-lb

step 2: 70 ft-lb (reverse pattern)

step 3: 85 ft-lb

damper (harmonic balancer) bolt

(Ford spec 70-90) oil

note: use automatic transmission fluid as lubricant when pressing damper on

flexplate bolts

(Ford spec 75-85) sealer

note: 1) see drawing for pattern

intake manifold bolts

(Ford spec 32-35) 3/8-16 sealer

note: 1) see drawing for pattern

exhaust manifold bolts

(Ford spec 18-24) 3/8-16 hi temp antiseize

note: 1) see drawing for pattern

timing chain sprocket bolt

torqued to 40 ft-lb (Ford spec 40-45) 3/8-16 (Fel-Pro Grey Bolt Prep)

cam retainer plate

(Ford spec 12-15) (Fel-Pro Grey Bolt Prep)

oil pan bolts

(Ford spec 9-11) 5/16-18 oil

oil drain plug

(Ford spec 15-20) 1/2-20 oil

water pump bolts

(torque 12-18) 5/16-18 antiseize

timing cover bolts

(torque 12-18) (Fel-Pro Grey Bolt Prep)

oil pump pickup

(Ford spec 12-15) Loctite 242

oil pump cover plate

(Ford spec 9-11) 1/4-20 Loctite 242

oil pump body

(torque 12-15) Loctite 242

oil filter adapter

(Ford 12-15) 5/16-18 sealer

spark plugs

(Ford spec 15-25) 18mm antiseize

bottom pulley to damper

(Ford spec 35-50) oil

valve cover

(Ford spec 4-7) 1/4-20 oil

fuel pump to timing cover

(Ford spec 20-25) 3/8-16 antiseize

fan to water pump

(Ford spec 12-18) 5/16-24 antiseize

carburetor to intake

(Ford spec 12-15) 5/16-18 antiseize

water pump

(Ford spec 20-25) 3/8-16 sealer

rocker shafts

(Ford spec 40-45) 3/8-16 antiseize

distributor clamp

(Ford spec 10 aluminum intake) antiseize

(Ford spec 12 iron intake) antiseize

motor mounts

(Ford spec 45-60) 7/14-14 dry

thermostat housing

(Ford spec 12-15) sealer

water temp sender

(Ford spec 10) antiseize

RUN-IN: -----------------------------------------------------------------

Make sure you don't have any loose wires or hoses in the way of the fan

before firing the engine. It is a great temptation to just start it up

with nonessentials hanging hither and yon.

Pour in 5 quarts of your favorite brand of non-synthetic oil, 10-30 or 10-40

weight, one bottle of General Motors Engine Oil Supplement, and screw

on an oil filter. It probably wouldn't hurt to fill the filter before

putting it on.

With the "+"coil wire disconnected and spark plugs out, crank the engine over

until oil comes out the pushrods, or use an engine priming tool and a drill.

Attach the coil wire and valve covers, put the plugs in, attach plug wires.

Fill the radiator with straight water.

Start the motor and run it up to 2000 RPM for 20 minutes to break in the cam.

DO NOT IDLE. If you don't have a tach handy, run it up to a fast idle, then

guess at twice as fast. Wedge a piece of cardboard or folded paper between

the idle stop screw and throttle linkage.

Use the timing light to set the timing to 8 degrees at idle; it's okay to let

the engine to drop to idle for a few moments to do this.

Smoke and noise will come from the motor as paint burns off, etc. Ignore

anything that doesn't sound terminal. Water temp will probably go right on

up there; it's okay as long as it doesn't go over 230 or boil over. If you

have near neighbors remember this will make a fair amount of noise.

Shut down. Change oil, filter, drain radiator and fill with 50/50 antifreeze

or other coolant. Take care of any leaks or problems. Let engine cool.

Retorque heads by backing off each bolt 1/8 turn and bringing back up to 70

ft-lb. You may have to remove the exhaust manifolds to get to the outside

head bolts. IF YOU DON'T RETORQUE THE HEADS YOU MAY BLOW A GASKET

Fire the engine back up and adjust valves while running at operating

temperature. The simplest way is to remove the valve cover, back off until

the rocker clacks, tighten until the noise stops, and slowly tighten another

1/4 turn. The engine will run rough and may try to die while doing this.

Break in by driving around for about a hundred miles. Try not to idle in

traffic. Change oil and filter again. Check for leaks. The engine is

ready to drive. At 3K miles you can change to synthetic oil if you wish.

Oil Viscosity:

Use the lowest viscosity oil required to maintain hot idle oil pressure of

at least 25 psi. This will circulate the maximum amount of oil through the

bearings. Very thick oil just goes right through the popoff valve built

into the oil pump and you can be starving the bearings while the guage

happily reads 60-80 PSI.