brought to you by: Dave Williams

This page: www.bacomatic.org/~dw/lt1/lt1.htm

Main page:

http://www.bacomatic.org/~dw/index.htm

Last Updated: 21 Jun 2005

Author: Dave Williams; dlwilliams=aristotle=net

The 229 V6 in my 1980 Malibu station wagon is no powerhouse, but it runs well and is good on gas. However, it has a horrendous rear main seal leak, typical of most Chevy V6s and V8s of the period. Chevy had used a different rubber for the rear main seal, and it hardened and cracked off in chunks, so when you pul out from a stop, oil slops out the back of the pan and all over the exhaust crossover pipe.

I wasn't thrilled about trying to replace the seal from underneath. It's just barely within the bounds of possibility, and the suck factor would be high. An engine R&R, given it's fully loaded with accessories, isn't much more fun. If the 229 has to come out, it sure as heck isn't going to go back in, particularly since the wagon is the new designated trailer-towing vehicle after I sold Thunder.

I bought a wrecked 1995 Camaro with an LT1 in it. It was one of those ideas that looked good at the time. But I hadn't taken the time to do my homework; the LT1 wouldn't accept any of the wagon's accessories. Different power steering pump fittings - not that the hoses would have stretched to the other side, where the LT1 put its pump. Different AC compressor, with alien fittings. The wagon's old A6 system worked fine and had a fresh charge of R12. Even the alternator wiring was different. And the V6's accessories wouldn't bolt to the LT1, because the LT1 had no water pump pulley, and every belt wanted to loop over the water pump.

Being stubborn, I decided to make the LT1 work. I didn't want to completely redo all the accessories and AC, or I would have simply put the Buick Grand National engine in. That's why I didn't put the GN engine in; I thought, "yeah, a Chevy V8, all the V6 stuff will bolt right up." Sometimes I'm a moron.

Anyway, the LT1 had been badly damaged in the crash. The block was broken, among other things. So it had to come all the way apart. Putting it back together, things started to get... a little strange.

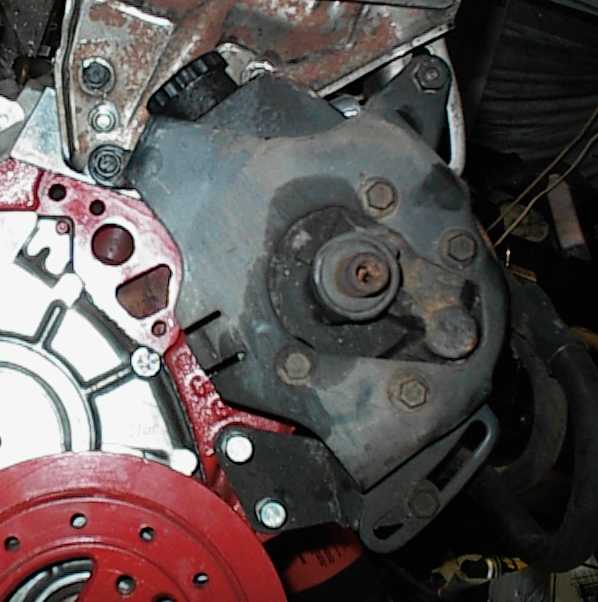

This is the original donor engine being disassembled. The block had been

cracked in the wreck, so it wasn't going to be re-used. Here, I've removed all

the pistons and I'm ready to pull the crank hub. The LT1 doesn't use a

harmonic balancer like a regular small block Chevy. Instead, it has a crank

hub, which simply presses on with no key to align it. The balancer then bolts

to the hub. There are no timing marks on the balancer, since the timing is

set by the position of the Optispark distributor in the timing cover.

This is the original donor engine being disassembled. The block had been

cracked in the wreck, so it wasn't going to be re-used. Here, I've removed all

the pistons and I'm ready to pull the crank hub. The LT1 doesn't use a

harmonic balancer like a regular small block Chevy. Instead, it has a crank

hub, which simply presses on with no key to align it. The balancer then bolts

to the hub. There are no timing marks on the balancer, since the timing is

set by the position of the Optispark distributor in the timing cover.

Chevrolet, in their wisdom, went to some very large diameter bolts to hold the

balancer on; larger than anything else in the known universe, which is why my

Lisle balancer puller tool's slots were too small to pass the bolts. So it's

time for some tool modification...

Chevrolet, in their wisdom, went to some very large diameter bolts to hold the

balancer on; larger than anything else in the known universe, which is why my

Lisle balancer puller tool's slots were too small to pass the bolts. So it's

time for some tool modification...

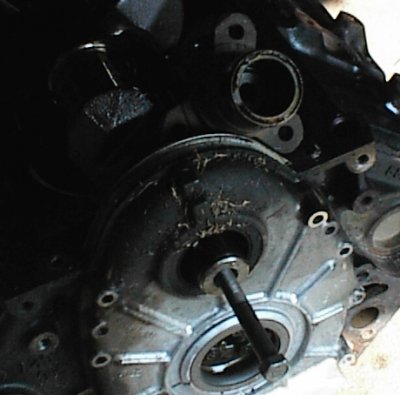

Here's a dim picture of the hub, laying above the timing cover. I nearly

broke the tool before looking in the hub with a flashlight. Instead of being

a straight bore like anything else, there's a web in the hub, with a hole just

large enough to pass the balancer bolt. All I'd been doing was trying to

break the web out. So I screwed a bolt into the end of the crank, through the

hole in the web, to get something to push on.

Here's a dim picture of the hub, laying above the timing cover. I nearly

broke the tool before looking in the hub with a flashlight. Instead of being

a straight bore like anything else, there's a web in the hub, with a hole just

large enough to pass the balancer bolt. All I'd been doing was trying to

break the web out. So I screwed a bolt into the end of the crank, through the

hole in the web, to get something to push on.

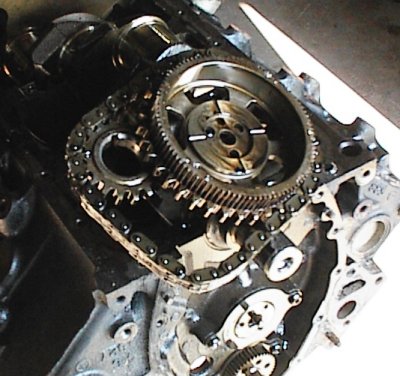

Here's the LT1's timing set. Plain old silent chain, ordinary-looking lower

sprocket, and the special LT1 upper sprocket, with the gear on the back to

drive the water pump idler gear several times crank speed. This is a $150

timing set.

Here's the LT1's timing set. Plain old silent chain, ordinary-looking lower

sprocket, and the special LT1 upper sprocket, with the gear on the back to

drive the water pump idler gear several times crank speed. This is a $150

timing set.

Optispark distributor, back side.

Optispark distributor, back side.

Optispark distributor, front side.

Optispark distributor, front side.

Just the cap costs $100, and you have to pull the harmonic balancer to get to

it. Water pump too, unless you're a contortionist. Ford used the same setup

on their flathead V8s until they upgraded to a distributor on a stick like the

rest of the world. Chevy devolved...

This is a second LT1 I got, as a short block. It came with a milk crate full

of spare rods and pistons, too. This one had two bolt mains. The hole in the

side of the oil pan was a clue there was a problem inside; here, the condition

of the windage tray should peg the clue meter.

This is a second LT1 I got, as a short block. It came with a milk crate full

of spare rods and pistons, too. This one had two bolt mains. The hole in the

side of the oil pan was a clue there was a problem inside; here, the condition

of the windage tray should peg the clue meter.

Screwdriver tip points to very short connecting rod. The powder-metal rods in

late models have a tendency to break. Complete disassembly showed it might

not have been the rod's fault this time. The piston pin was broken, one side

still clamped in the pin end, the other in the pan. In the milk crate full of

spares, two other rod/piston pairs had broken pins. The LT1 uses a

lightweight, skirtless piston, and it uses a thinwall wristpin. The pins are

brittle; of 21 rod/piston pairs I checked, three were broken. That's not good

odds.

Screwdriver tip points to very short connecting rod. The powder-metal rods in

late models have a tendency to break. Complete disassembly showed it might

not have been the rod's fault this time. The piston pin was broken, one side

still clamped in the pin end, the other in the pan. In the milk crate full of

spares, two other rod/piston pairs had broken pins. The LT1 uses a

lightweight, skirtless piston, and it uses a thinwall wristpin. The pins are

brittle; of 21 rod/piston pairs I checked, three were broken. That's not good

odds.

Here's a shot up the bore with the crank out. You can see the left side of

the wristpin is missing.

The crank was undamaged, and I

decided to use it instead of the one out of the first block.

Here's a shot up the bore with the crank out. You can see the left side of

the wristpin is missing.

The crank was undamaged, and I

decided to use it instead of the one out of the first block.

Another friend gave me a third LT1 block. This was another four bolt

main block, and it had an unworn standard bore. Problem was, Arkansas'

infamous humidity had worked on it for a couple of years. It needed a lot of

TLC to get it back into useable shape.

Another friend gave me a third LT1 block. This was another four bolt

main block, and it had an unworn standard bore. Problem was, Arkansas'

infamous humidity had worked on it for a couple of years. It needed a lot of

TLC to get it back into useable shape.

Every lifter bore, every main journal, the main webs, everything, had to be

wire wheeled or sanded. It took a long time.

Every lifter bore, every main journal, the main webs, everything, had to be

wire wheeled or sanded. It took a long time.

The Mystery Hole. This block had a 1/4 NPT tapped boss that did nothing that

I could figure out. The other two blocks didn't have it. Some later Vortec

V8s and V6s also have mystery holes similar to this one.

The Mystery Hole. This block had a 1/4 NPT tapped boss that did nothing that

I could figure out. The other two blocks didn't have it. Some later Vortec

V8s and V6s also have mystery holes similar to this one.

Ah, first you strip the oil plug out with the square bit. Then you drill it

out, drive in the chisel, and turn the mangled remains of the plug out...

Ah, first you strip the oil plug out with the square bit. Then you drill it

out, drive in the chisel, and turn the mangled remains of the plug out...

...then you run a tap in to repair the mangulated threads.

...then you run a tap in to repair the mangulated threads.

Tapping all the holes to clear the rust and gick out. It's good exercise for

the wrists. At least, that's what I keep telling myself.

Tapping all the holes to clear the rust and gick out. It's good exercise for

the wrists. At least, that's what I keep telling myself.

I miked the main bores, miked the crank, popped the bearings and crank in,

tightened the main caps... and the crank wouldn't turn. Vertical clearance

was fine with both the micrometer and Plastigage. I pulled the center three

bearings out, set up a dial indicator, and spun the crank. It was straight.

I laid a straightedge in the main saddles of the block. They were straight.

I finally took a look at the center three main caps... and they were all

shifted visibly to one side. They were 4-bolt caps, but they weren't for that

particular block. The front and rear caps were fine.

I miked the main bores, miked the crank, popped the bearings and crank in,

tightened the main caps... and the crank wouldn't turn. Vertical clearance

was fine with both the micrometer and Plastigage. I pulled the center three

bearings out, set up a dial indicator, and spun the crank. It was straight.

I laid a straightedge in the main saddles of the block. They were straight.

I finally took a look at the center three main caps... and they were all

shifted visibly to one side. They were 4-bolt caps, but they weren't for that

particular block. The front and rear caps were fine.

At this point, I was out a full day of cleaning, a set of freeze plugs, a can

of paint, a set of cam bearings, and a $80 set of pistons. If I had been

smart, I would have tossed the block and the pistons in the trash, chances of

finding another standard-bore block being remote, and bored the block from the

engine that had tossed a rod; the scratches in the cylinder would have cleaned

up at .030 or .040. Instead, I wound up paying close to $160 to have this

particular block align honed. The shop I farmed it out to honed it a

lot; as in, the timing chain then flapped in the wind when I started

putting it back together again. Fortunately, short timing chains are

available for Chevys that have been align bored or honed. They cost $130. So

I'm out close to $300 because I was too stubborn to write off all the prep

time I'd put in this particular block. This is known as "penny wise and pound

foolish." Or, in practical terms, another yawning hole in my checking account

that I'll have to rationalize as "a learning experience."

Here we are, back from the other shop, cleaned up, and ready to try again.

Honing oil is full of grit from the stones wearing down, so all the little oil

passages have to be thoroughly cleaned, including flushing around the cam

bearings with solvent and the pressure washer. Yes, I should have knocked the

cam bearings out for cleaning, but it was another case of the stubborns. It

was all sparkly clean behind the bearings from when I had cleaned the block,

so there was no gick back there to hold any grit.

Here we are, back from the other shop, cleaned up, and ready to try again.

Honing oil is full of grit from the stones wearing down, so all the little oil

passages have to be thoroughly cleaned, including flushing around the cam

bearings with solvent and the pressure washer. Yes, I should have knocked the

cam bearings out for cleaning, but it was another case of the stubborns. It

was all sparkly clean behind the bearings from when I had cleaned the block,

so there was no gick back there to hold any grit.

Most Detroit engines sit at a 5 degree or so angle in the chassis, to lower

the transmission and driveshaft. In C4 and later Corvettes, and later

Camaros, the engine sits level. Air bubbles in the older engines would make

their way to the thermostat housing and out, but with the engine sitting

level, that doesn't work so well. The last of the L98s got bleeder ports on

the backs of the heads when in the Corvette and Camaro, and so did the LT1,

even when it was in an Impala. There's a crossover tube at the back with

washers and trapped O-rings, to circulate bubbles and coolant out of the

heads.

Most Detroit engines sit at a 5 degree or so angle in the chassis, to lower

the transmission and driveshaft. In C4 and later Corvettes, and later

Camaros, the engine sits level. Air bubbles in the older engines would make

their way to the thermostat housing and out, but with the engine sitting

level, that doesn't work so well. The last of the L98s got bleeder ports on

the backs of the heads when in the Corvette and Camaro, and so did the LT1,

even when it was in an Impala. There's a crossover tube at the back with

washers and trapped O-rings, to circulate bubbles and coolant out of the

heads.

I disassembled and cleaned the oil filter adapter/bypass. The stock bypass is

very weak. I often tap and plug the bypass hole to ensure full flow through

the filter. This time, I found a stiffer spring. It was an adventure getting

the spring and its retaining washer in place, then crimping the edges back

over. All it takes is five hands and the strength of Superman.

I disassembled and cleaned the oil filter adapter/bypass. The stock bypass is

very weak. I often tap and plug the bypass hole to ensure full flow through

the filter. This time, I found a stiffer spring. It was an adventure getting

the spring and its retaining washer in place, then crimping the edges back

over. All it takes is five hands and the strength of Superman.

The long, weird bolts clock the oil cooler adapter in relation to the block.

The long, weird bolts clock the oil cooler adapter in relation to the block.

Here the front oil plugs and cam are installed. Some LT1s had .030" holes

drilled in the lifter gallery plugs to purge air and eliminate lifter rattle

if the engine has been sitting a long time. I didn't feel like drilling some

new plugs, so I drove the old ones back in after rodding out the oil passages,

staked the perimeters heavily, and then ran a small bead of epoxy around the

outer edges. I don't think they'll go anywhere.

Here the front oil plugs and cam are installed. Some LT1s had .030" holes

drilled in the lifter gallery plugs to purge air and eliminate lifter rattle

if the engine has been sitting a long time. I didn't feel like drilling some

new plugs, so I drove the old ones back in after rodding out the oil passages,

staked the perimeters heavily, and then ran a small bead of epoxy around the

outer edges. I don't think they'll go anywhere.

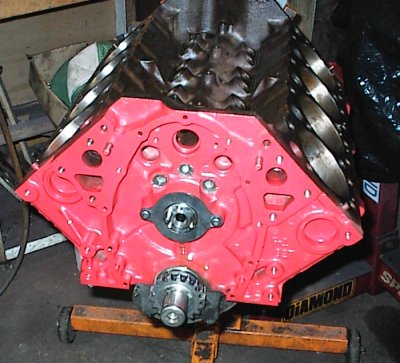

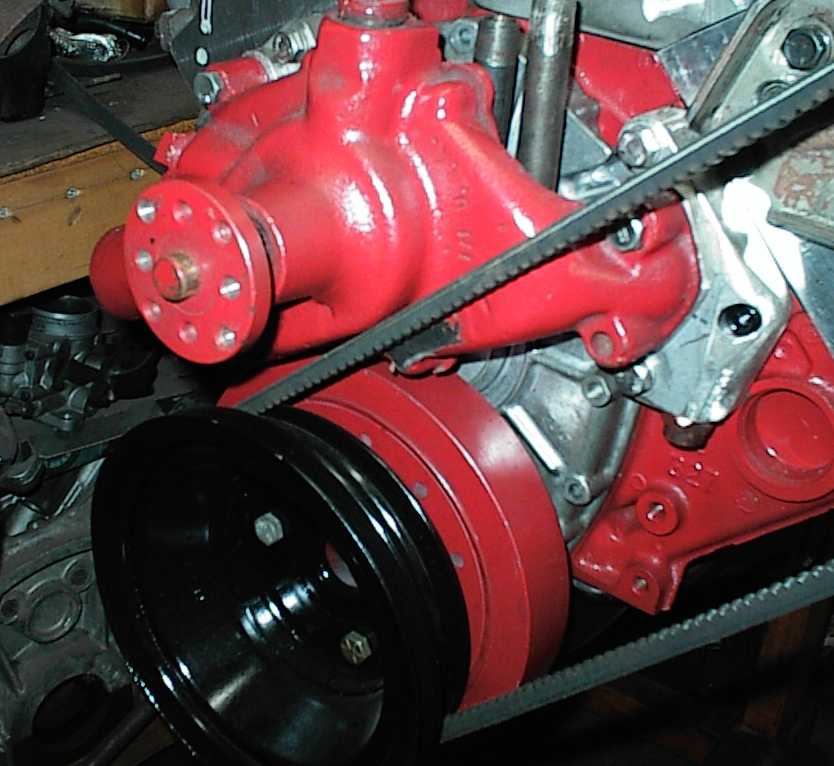

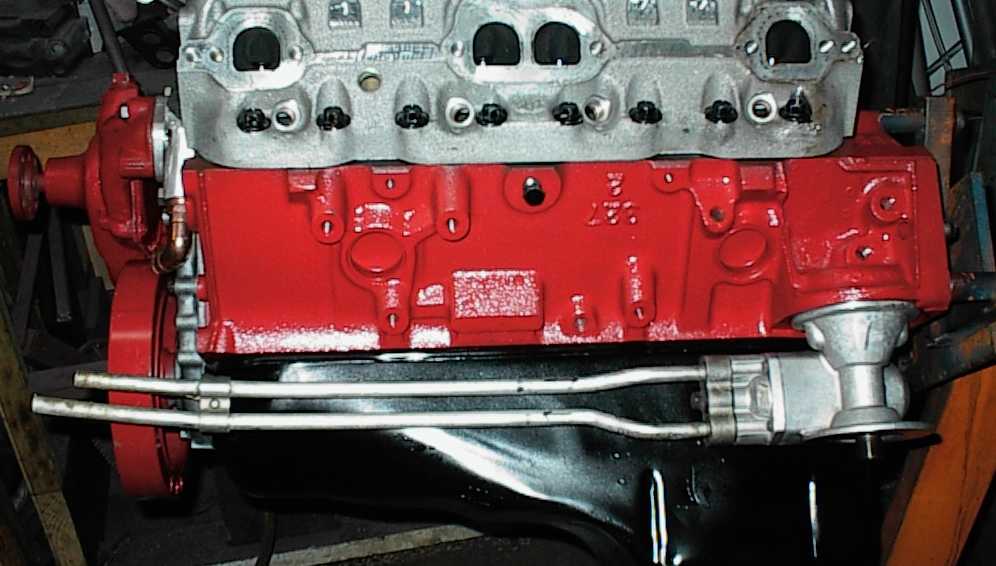

Trial fitting all the bits. The Ford Red paint looks sort of spiffy, doesn't

it?

Trial fitting all the bits. The Ford Red paint looks sort of spiffy, doesn't

it?

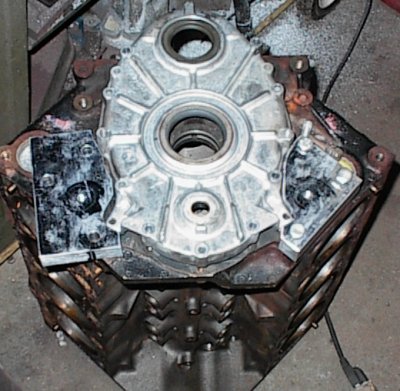

Large hole in the middle was for the ball bearing on the end of the LT1 water

pump drive shaft. It's not used with the new retrofit bits.

Large hole in the middle was for the ball bearing on the end of the LT1 water

pump drive shaft. It's not used with the new retrofit bits.

Hanging rods. They're all numbered and dotted to show which way the rods go.

Hanging rods. They're all numbered and dotted to show which way the rods go.

Getting ready for grinding the valve seats. I put a nice three-angle valve

job in, and a set of brand-new Vortec valves and springs. I also ceramic-

coated the valves, which should help reduce any tendency to ping.

Getting ready for grinding the valve seats. I put a nice three-angle valve

job in, and a set of brand-new Vortec valves and springs. I also ceramic-

coated the valves, which should help reduce any tendency to ping.

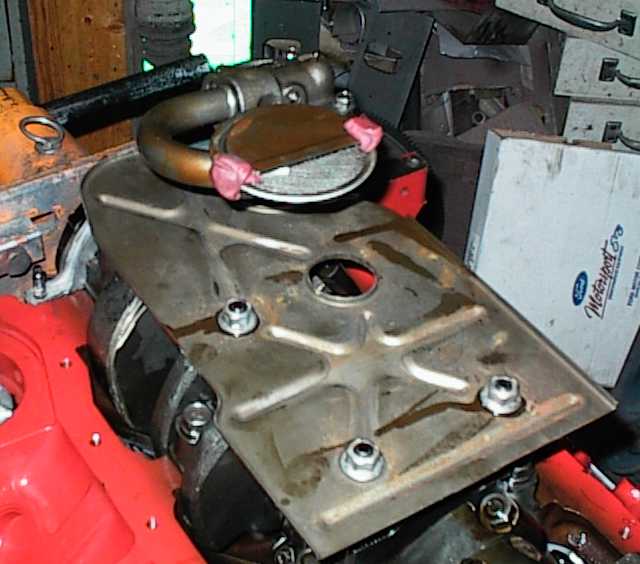

Here we are, another mockup. Heavy L98 350 harmonic balancer, early short

water pump, Offenhauser Dual-Port 360 intake, old Mercury Marine valve covers.

That's an electronic Quadrajet sitting on top.

Here we are, another mockup. Heavy L98 350 harmonic balancer, early short

water pump, Offenhauser Dual-Port 360 intake, old Mercury Marine valve covers.

That's an electronic Quadrajet sitting on top.

Another angle. Note the timing pointer - the LT1 didn't have one to start

with. The timing cover had to be spotfaced a bit, but the bolt holes lined up

okay.

Another angle. Note the timing pointer - the LT1 didn't have one to start

with. The timing cover had to be spotfaced a bit, but the bolt holes lined up

okay.

The LT1 timing chain cover has a thick lip. There's only a thin slot for oil

to bleed back between the timing chain and the front main cap. No problem,

though.

The LT1 timing chain cover has a thick lip. There's only a thin slot for oil

to bleed back between the timing chain and the front main cap. No problem,

though.

Lots of late Chevy V8s and V6s have this little half-size windage tray. It

covers the sump part of the pan, which is all that is really needed.

Lots of late Chevy V8s and V6s have this little half-size windage tray. It

covers the sump part of the pan, which is all that is really needed.

The big hole is for the dipstick. The self-locking nuts are also Loctited.

The big hole is for the dipstick. The self-locking nuts are also Loctited.

That's the new-style 3/4" pickup tube, as opposed to the old 5/8" tube. Chevy changed over somewhere in the late '80s. The clay is to verify proper pickup tube height.

Oddly enough, both the the LT1 core motors I got had high volume oil pumps on

them, apparently from the factory.

Most people pull the old gear while taking the core engine apart. I leave it

on since it provides a good place to wrap the chain around the nose when you

put the crank in the cleaning tank.

Most people pull the old gear while taking the core engine apart. I leave it

on since it provides a good place to wrap the chain around the nose when you

put the crank in the cleaning tank.

Ring gapping again...

Ring gapping again...

Special LT1 head gaskets were only a couple of dollars more than ordinary

Chevy gaskets. It was nice not to get raped for anything LT1-specific, for a

change.

Special LT1 head gaskets were only a couple of dollars more than ordinary

Chevy gaskets. It was nice not to get raped for anything LT1-specific, for a

change.

The first year or two of LT1 head gaskets were extended into the lifter

gallery and had holes for the pushrods. According to lore, the holes were to

hold the pushrods up so they could be installed first, then the head, to speed

assembly. Might even be true... later LT1s got rid of the pushrod holes, but

these Fel-Pro replacement gaskets are the early type.

I managed to snag a Vortec lower intake, and thought briefly about using it

instead of the Offy. I didn't feel like redrilling the intake or modifying

the heads again, so I decided to stay with the Offy. Remember both the LT1

and the Vortec use different bolt patterns from each other and either

of the two old-style (original, or 75-degree center bolt) intake

manifold patterns.

I managed to snag a Vortec lower intake, and thought briefly about using it

instead of the Offy. I didn't feel like redrilling the intake or modifying

the heads again, so I decided to stay with the Offy. Remember both the LT1

and the Vortec use different bolt patterns from each other and either

of the two old-style (original, or 75-degree center bolt) intake

manifold patterns.

Remember, Chevy stuff all interchanges, and they're easy to work on...

Another view of the Vortec manifold. Some injector bungs, weld up a lid, slap

a throttle body on somewhere, and it'd be a nice setup. It's very similar to

the old CrossFire Injection, except with larger runners.

Another view of the Vortec manifold. Some injector bungs, weld up a lid, slap

a throttle body on somewhere, and it'd be a nice setup. It's very similar to

the old CrossFire Injection, except with larger runners.

Getting ready to transfer-punch the heads for the new intake manifold bolt

holes. First, a pair of old head gaskets so the heads sit at the right

height.

Getting ready to transfer-punch the heads for the new intake manifold bolt

holes. First, a pair of old head gaskets so the heads sit at the right

height.

Now everything is mocked up in place.

Now everything is mocked up in place.

Here are the finished heads. The LT1 holes are plugged with set screws and

silicone sealer; if I ever want to slap an LT1 manifold back on, I can remove

the set screws and do so. The head mating surface on the Offy intake is

skeletonized and the LT1 holes would let stuff fall through into the lifter

galley if they weren't plugged.

Here are the finished heads. The LT1 holes are plugged with set screws and

silicone sealer; if I ever want to slap an LT1 manifold back on, I can remove

the set screws and do so. The head mating surface on the Offy intake is

skeletonized and the LT1 holes would let stuff fall through into the lifter

galley if they weren't plugged.

A standard 283 water pump almost lines up with the LT1 inlet holes and upper bolt holes. The 229 uses a long pump, so the short 283 pump gives me 1- 1/2" to form adapters.

The first thing I did was get some gaskets so I could use them to mark off the

bolt and water holes. This turned out to be a three-day event involving four

parts stores. LT1 gaskets aren't normal stock items. Finally, NAPA came up

with a pair, at $3.50 each. At least $3 of that was probably the big piece of

cardboard and the shrinkwrap! Anything specific to an LT1 is expensive.

The first thing I did was get some gaskets so I could use them to mark off the

bolt and water holes. This turned out to be a three-day event involving four

parts stores. LT1 gaskets aren't normal stock items. Finally, NAPA came up

with a pair, at $3.50 each. At least $3 of that was probably the big piece of

cardboard and the shrinkwrap! Anything specific to an LT1 is expensive.

I had some 1-1/8" thick, 3-1/2" wide aluminum bar on hand. Oddball size, but

big enough, anyway. I made a rough template out of file folder stock to get

started.

I had some 1-1/8" thick, 3-1/2" wide aluminum bar on hand. Oddball size, but

big enough, anyway. I made a rough template out of file folder stock to get

started.

Black it out with ink, transfer the hole locations from the gaskets, drill,

chamfer.

Black it out with ink, transfer the hole locations from the gaskets, drill,

chamfer.

Now we're sawing and grinding. I didn't bother to come up with special

patterns, I just kept whacking at them until they fit.

Now we're sawing and grinding. I didn't bother to come up with special

patterns, I just kept whacking at them until they fit.

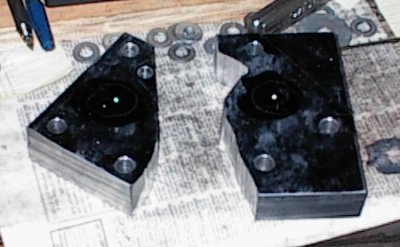

Roughed out with the bandsaw, die grinder, and belt sander. The adapters now

clear the timing cover. All the gasket-spot-transfer-punched mounting holes

wound up aligned okay, much to my surprise...

Roughed out with the bandsaw, die grinder, and belt sander. The adapters now

clear the timing cover. All the gasket-spot-transfer-punched mounting holes

wound up aligned okay, much to my surprise...

Big C clamp holds water pump in place while I mark where the spots to drill

the pump mounting holes. You can see the extra metal on the driver's side

adapter has been machined off and the corners rounded.

Big C clamp holds water pump in place while I mark where the spots to drill

the pump mounting holes. You can see the extra metal on the driver's side

adapter has been machined off and the corners rounded.

After center punching the hole locations and drilling the mounting holes, I'm

tapping the pump mounting holes.

After center punching the hole locations and drilling the mounting holes, I'm

tapping the pump mounting holes.

The LT1 water ports in the block were slightly smaller than the 283 pump

outlets. I tapered the holes with the die grinder.

The LT1 water ports in the block were slightly smaller than the 283 pump

outlets. I tapered the holes with the die grinder.

If you look, you'll see I didn't use the LT1's upper pump mounting holes.

They conflicted with the 283 holes. However, the LT1 block has many extra

bosses and tapped holes; two of them were just above the water pump holes.

That's why the adapters reach around the flanges on the timing cover, so they

can grab the top holes.

An hour or so with the die grinder hollowed the backs out. It was easier than

setting them up on the milling machine. I left some metal inside to

accomodate the lower water pump bolts. It shouldn't affect flow enough to

worry about.

An hour or so with the die grinder hollowed the backs out. It was easier than

setting them up on the milling machine. I left some metal inside to

accomodate the lower water pump bolts. It shouldn't affect flow enough to

worry about.

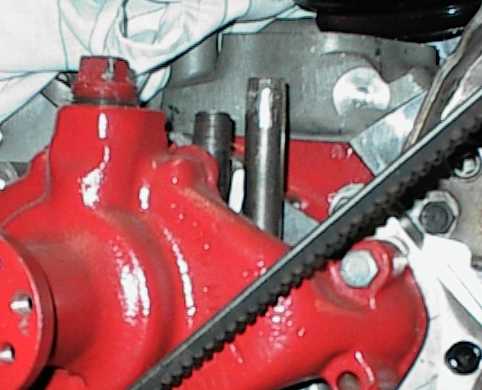

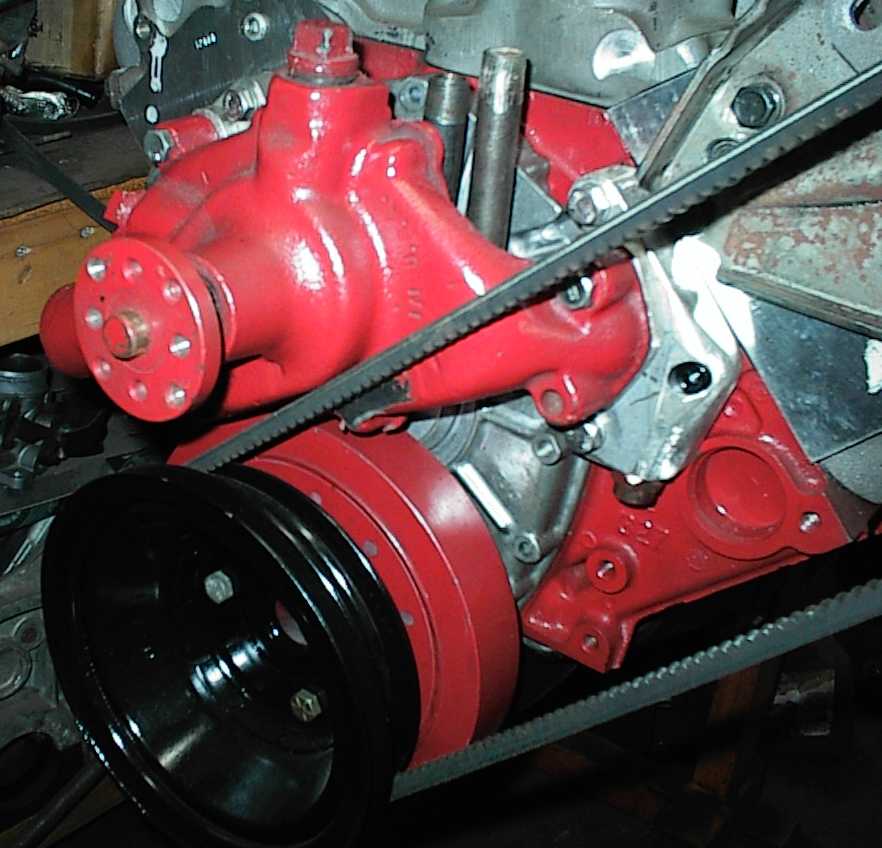

Yes! Finally! The 283 pump is bolted down to the adaptors. There's still

some finish work to do, but they're almost done.

Yes! Finally! The 283 pump is bolted down to the adaptors. There's still

some finish work to do, but they're almost done.

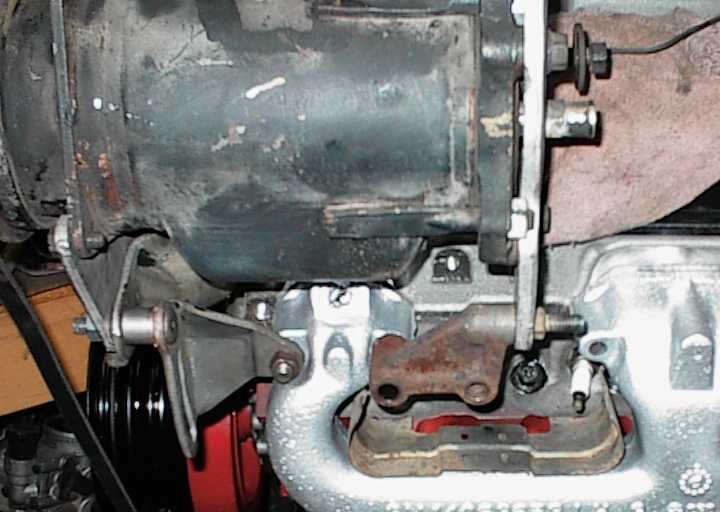

A view from the bottom.

A view from the bottom.

I needed another 3/8" to push the water pump flange out to where it needed to

be. I cut these spacers out of 3/8" plate. Since the bypass hole from the

pump is blocked off, I'll need to run another bypass somewhere else, probably

a few holes drilled in the thermostat.

I needed another 3/8" to push the water pump flange out to where it needed to

be. I cut these spacers out of 3/8" plate. Since the bypass hole from the

pump is blocked off, I'll need to run another bypass somewhere else, probably

a few holes drilled in the thermostat.

And here they are... the circle around the Allen bolt shows where it needs to

be counterbored. The passenger side adapter has a countersunk Allen to clear

the part of the spacer that covers the water pump bypass.

And here they are... the circle around the Allen bolt shows where it needs to

be counterbored. The passenger side adapter has a countersunk Allen to clear

the part of the spacer that covers the water pump bypass.

Skipping ahead a bit, here the adapters are, partway through final assembly.

The 1980 power steering pump brackets tuck the pump close in to the front of

the block; I rounded off the adapter to maximize clearance.

Skipping ahead a bit, here the adapters are, partway through final assembly.

The 1980 power steering pump brackets tuck the pump close in to the front of

the block; I rounded off the adapter to maximize clearance.

Here's the only real problem so far. The short pump is shaped differently

from the long pump, of course... the belt hits the body of the short pump. On

a long pump, the belt would be going under the snout with plenty of room.

Here's the only real problem so far. The short pump is shaped differently

from the long pump, of course... the belt hits the body of the short pump. On

a long pump, the belt would be going under the snout with plenty of room.

5/8" copper tubing for the water lines. These are the main lines coming out

of the block; each one handles the entire water flow for its side of the

engine. It doesn't look like enough, but it should be plenty. Most

thermostats have about the same area when open.

5/8" copper tubing for the water lines. These are the main lines coming out

of the block; each one handles the entire water flow for its side of the

engine. It doesn't look like enough, but it should be plenty. Most

thermostats have about the same area when open.

Turned up, with female NPT fittings for the hose barbs.

Turned up, with female NPT fittings for the hose barbs.

The copper tubes need to be supported well or they might crack. First, we

start with a chunk of aluminum bar stock...

The copper tubes need to be supported well or they might crack. First, we

start with a chunk of aluminum bar stock...

...then we drill some holes, and tap some of them, so we can bolt two pieces

together...

...then we drill some holes, and tap some of them, so we can bolt two pieces

together...

Then we drill some really big holes to run the copper fittings through.

Then we drill some really big holes to run the copper fittings through.

Tapping some different holes to hold the adapter to the mounting bracket.

Tapping some different holes to hold the adapter to the mounting bracket.

Sawing off some extra that we don't need...

Sawing off some extra that we don't need...

Pipes coming up to the bottom of the new thermostat housing, which is offset

off the intake manifold.

Pipes coming up to the bottom of the new thermostat housing, which is offset

off the intake manifold.

Since I wasn't planning to use either the distributor or water pump drives

from the LT1, the holes needed to be blocked off. You can't just change to a

different cover - nothing else fits an LT1. I started by cutting some chunks

of aluminum with the saw.

Since I wasn't planning to use either the distributor or water pump drives

from the LT1, the holes needed to be blocked off. You can't just change to a

different cover - nothing else fits an LT1. I started by cutting some chunks

of aluminum with the saw.

Turning square chunks to round chunks on the lathe. The holes in the cover

are stepped, with a rubber seal pressed in; I'm duplicating the step in the

plug.

Turning square chunks to round chunks on the lathe. The holes in the cover

are stepped, with a rubber seal pressed in; I'm duplicating the step in the

plug.

And here we are, finished...

And here we are, finished...

Upper plug in progress. It's a lot thicker than the large plug.

Upper plug in progress. It's a lot thicker than the large plug.

Here's the inside of the timing cover. The plugs are a snug fit, with epoxy

in the stepped area and epoxy on the back. A small button head screw will go

in each one to close off the threaded holes.

Here's the inside of the timing cover. The plugs are a snug fit, with epoxy

in the stepped area and epoxy on the back. A small button head screw will go

in each one to close off the threaded holes.

The LT1 has a little (plastic!) stub shaft that bolts down into the lifter

valley, with a gear to drive the oil pump. That gear is normally on the

distributor, but the LT1's distributor was up front.

The LT1 has a little (plastic!) stub shaft that bolts down into the lifter

valley, with a gear to drive the oil pump. That gear is normally on the

distributor, but the LT1's distributor was up front.

Since we're going retro, I wanted to put an ordinary HEI in the back, which

would be easy since the Offy had a hole for it.

Having been burned on distributor gear mismatches before, at least on Fords,

where the incorrect gear will destroy both the gear and the camshaft, I pulled

the gear off the stub shaft to put on the HEI, so the cam would have the same

gear it left the factory with. No compatibility problems.

Having been burned on distributor gear mismatches before, at least on Fords,

where the incorrect gear will destroy both the gear and the camshaft, I pulled

the gear off the stub shaft to put on the HEI, so the cam would have the same

gear it left the factory with. No compatibility problems.

In their wisdom, Chevrolet made the inside diameter of the LT1's stub shaft

gear smaller than for a distributor! So I bored the thing out to fit.

The HEI ignition module uses thermally-conductive grease to make a good

connection to the distributor housing, which it uses as a heat sink.

The HEI ignition module uses thermally-conductive grease to make a good

connection to the distributor housing, which it uses as a heat sink.

Corvette manifolds have siamesed center ports. Some were cast, some were

fabricated from tubing, and neither were much to brag about. The Camaro

manifolds are *much* better. Notice the dramatically upswept runners.

Corvette manifolds have siamesed center ports. Some were cast, some were

fabricated from tubing, and neither were much to brag about. The Camaro

manifolds are *much* better. Notice the dramatically upswept runners.

The heat shields were mangled in the crash, as was almost everything else. I

ground the rivet heads away to remove them.

The heat shields were mangled in the crash, as was almost everything else. I

ground the rivet heads away to remove them.

The weird kink at the back is apparently to try to separate the last cylinder

from the first three. The first three do not overlap during the exhaust

event; the last one overlaps the next-to-last, so it comes in at a different

angle. Looks strange, but it's an attempt to reduce reversion into #5.

The Camaro manifolds tuck in close to the block. The Camaro's engine

compartment is fairly tight. The manifolds clear everything in the Malibu

just fine.

The Camaro manifolds tuck in close to the block. The Camaro's engine

compartment is fairly tight. The manifolds clear everything in the Malibu

just fine.

The passenger sides doesn't tuck in quite so tightly, but it's okay. The

bottom of the manifold was broken, along with so much else, in the crash. A

buddy used his stick welder and a nickel-iron rod to stick it back together.

The passenger sides doesn't tuck in quite so tightly, but it's okay. The

bottom of the manifold was broken, along with so much else, in the crash. A

buddy used his stick welder and a nickel-iron rod to stick it back together.

Both manifolds will get new brass studs before the engine goes in.

I couldn't use the driver's side manifold because the V6 air conditioning

compressor already occupied that space. So I found a '94 Vortec pickup truck

exhaust manifold. It has a 2-1/4" outlet,

same as the LT1 manifold. There was a rusty heat shield that I discarded.

I couldn't use the driver's side manifold because the V6 air conditioning

compressor already occupied that space. So I found a '94 Vortec pickup truck

exhaust manifold. It has a 2-1/4" outlet,

same as the LT1 manifold. There was a rusty heat shield that I discarded.

LT1 manifold, sandblasted and ceramic coated. No paint yet. Of course, the

manifold I had to replace was the one that wasn't broken...

LT1 manifold, sandblasted and ceramic coated. No paint yet. Of course, the

manifold I had to replace was the one that wasn't broken...

There was a big A.I.R. boss in the truck manifold. I welded a plug in, then

ground the boss out.

There was a big A.I.R. boss in the truck manifold. I welded a plug in, then

ground the boss out.

Ink and scribe lines are for porting the manifold to match the LT1 exhaust

ports. In their ultimate wisdom, GM raised the exhaust ports a bit on the LT1

to improve exhaust flow. But they didn't bother to raise the bolt pattern, so

there's a nasty step at the top if you bolt an early manifold or header to an

LT1 head.

The A.I.R. boss referred to previously.

The A.I.R. boss referred to previously.

The truck manifold is "Chevelle style" as I think of it, sweeping underneath

the spark plugs. All factory applications of this type of manifold have heat

shields to keep from cooking the plug wires.

The truck manifold is "Chevelle style" as I think of it, sweeping underneath

the spark plugs. All factory applications of this type of manifold have heat

shields to keep from cooking the plug wires.

The LT1 heads have angled spark plugs, which are also relocated to the exhaust

side of the combustion chamber. Standard heat shields hit the plugs. So I

cut and spliced them to get clearance.

Mercury Marine valve covers say "250HP." Hey, close enough...

Mercury Marine valve covers say "250HP." Hey, close enough...

The stock LT1 exhaust heat shields were torn up in the crash, so I made some

cardboard templates to make some new ones. Some GM applications don't use

shields, but those are prone to burn up valve cover gaskets. Yes, even the

fancy silicone rubber gaskets can char and break up!

The stock LT1 exhaust heat shields were torn up in the crash, so I made some

cardboard templates to make some new ones. Some GM applications don't use

shields, but those are prone to burn up valve cover gaskets. Yes, even the

fancy silicone rubber gaskets can char and break up!

Whatever alloy Chevy used didn't want to weld worth flip. It took a lot of

grinding to smooth them out.

Whatever alloy Chevy used didn't want to weld worth flip. It took a lot of

grinding to smooth them out.

I dug through the manifold pile at the local yard and found his - a 1992

Chevrolet 3/4 ton pickup truck manifold. It's virtually identical to any

early truck manifold, except it has a 2-1/4" outlet. Early ones were 1-3/4 or

2"

I dug through the manifold pile at the local yard and found his - a 1992

Chevrolet 3/4 ton pickup truck manifold. It's virtually identical to any

early truck manifold, except it has a 2-1/4" outlet. Early ones were 1-3/4 or

2"

O2 sensor bung in the back, should clear the Malibu firewall okay.

O2 sensor bung in the back, should clear the Malibu firewall okay.

There had been a heat shield wrapped around the front part. It had mostly

rotted away. There were some deep pits where the shield had been, but they

weren't bad enough to discard the manifold.

There had been a heat shield wrapped around the front part. It had mostly

rotted away. There were some deep pits where the shield had been, but they

weren't bad enough to discard the manifold.

Here's the truck manifold with the AC bracketry in place.

Here's the truck manifold with the AC bracketry in place.

...and a view from the other end.

...and a view from the other end.

The top bracket is an '80 Malibu power steering pump bracket. Brand new, too.

The bottom bracket is off an '89 Suburban with a 350. It bolts up perfectly

to the air conditioner part of the bracket, and has the same water pump part

as the V6 bracket. However, it has an extension below for an extra bracket,

that bolts to the block. The Malibu brackets are known for cracking; the

truck bracket appears to be an update. So I'll be using the truck bracket.

The top bracket is an '80 Malibu power steering pump bracket. Brand new, too.

The bottom bracket is off an '89 Suburban with a 350. It bolts up perfectly

to the air conditioner part of the bracket, and has the same water pump part

as the V6 bracket. However, it has an extension below for an extra bracket,

that bolts to the block. The Malibu brackets are known for cracking; the

truck bracket appears to be an update. So I'll be using the truck bracket.

Here is is, installed. You can see the extra brace bolted to the block.

Here is is, installed. You can see the extra brace bolted to the block.

Unfortunately, the pump's tank hits the water pump adapter.

Here's the V6 compressor bracket. On the V6, it spans two exhaust manifold

bolts, which are spaced closer than the V8 bolts. The front bolt hole is

okay, but the rear hangs off into empty space.

Here's the V6 compressor bracket. On the V6, it spans two exhaust manifold

bolts, which are spaced closer than the V8 bolts. The front bolt hole is

okay, but the rear hangs off into empty space.

I scrounged several V8 brackets, but the compressor pivot was in the wrong

place. So, off to modify the V6 bracket...

A chunk of 3/4 inch steel was available. Sharp viewers will notice that it's

one of the counterweights from my 2.5 four cylinder balance experiment.

A chunk of 3/4 inch steel was available. Sharp viewers will notice that it's

one of the counterweights from my 2.5 four cylinder balance experiment.

We saw the chunk into the approximate shape before moving to the milling

machine.

We saw the chunk into the approximate shape before moving to the milling

machine.

I needed a big notch milled in the casting, but there was no way to hold it in

the vise in the right orientation. So I bolted and tack welded it to a chunk

of steel and held on to that instead.

I needed a big notch milled in the casting, but there was no way to hold it in

the vise in the right orientation. So I bolted and tack welded it to a chunk

of steel and held on to that instead.

Here's the V6 casting welded to our chunk of machined steel. The bolt kept

them together and in alignment for welding.

Here's the V6 casting welded to our chunk of machined steel. The bolt kept

them together and in alignment for welding.

Finished lower bracket, with socket head cap screw torqued to 45 ft-lb and

welded in place, and the end ground to clear the pocket in the exhaust

manifold.

Finished lower bracket, with socket head cap screw torqued to 45 ft-lb and

welded in place, and the end ground to clear the pocket in the exhaust

manifold.

Another view of the bracket. It ought to be plenty strong. It has to be; the

old A6 compressor is pretty heavy!

Another view of the bracket. It ought to be plenty strong. It has to be; the

old A6 compressor is pretty heavy!

Front view of AC bracketry. This is all V6 Malibu stuff. I haven't done the

rear-upper bracket yet. Nothing is even close to matching the Offy intake to

the V6 AC compressor location, so that'll be a scratchbuilt part.

Front view of AC bracketry. This is all V6 Malibu stuff. I haven't done the

rear-upper bracket yet. Nothing is even close to matching the Offy intake to

the V6 AC compressor location, so that'll be a scratchbuilt part.

This is the LT1's oil cooler. The aluminum lines are brazed to the adapter,

and had rubber lines swaged to the ends, one going to the Camaro radiator, one

going to the LT1 water pump.

This is the LT1's oil cooler. The aluminum lines are brazed to the adapter,

and had rubber lines swaged to the ends, one going to the Camaro radiator, one

going to the LT1 water pump.

A short oil filter has to be used with the oil cooler.

A short oil filter has to be used with the oil cooler.

I cut the aluminum tubes off, then tapped the adapter block for 3/8 NPT

fittings.

I cut the aluminum tubes off, then tapped the adapter block for 3/8 NPT

fittings.

Problem with the AC belt - it rubbed the water pump. There wasn't enough

metal in the casting to grind adequate clearance. Drat!

Problem with the AC belt - it rubbed the water pump. There wasn't enough

metal in the casting to grind adequate clearance. Drat!

Upper AC compressor bracket. I made 1" standoffs to raise the flat parts over

the valve cover, then bolted them to the bosses on the Offenhauser manifold.

A piece of 1" bar stock was tapped for a 3/8" bolt. The braces themselves are

1/4" x 1" cold rolled steel. I had to bend a twist them slightly to align

things, so they look a little odd compared to the usual stamped steel brace.

However, it should be plenty strong, which is good enough.

Upper AC compressor bracket. I made 1" standoffs to raise the flat parts over

the valve cover, then bolted them to the bosses on the Offenhauser manifold.

A piece of 1" bar stock was tapped for a 3/8" bolt. The braces themselves are

1/4" x 1" cold rolled steel. I had to bend a twist them slightly to align

things, so they look a little odd compared to the usual stamped steel brace.

However, it should be plenty strong, which is good enough.

New plan for the AC belt. A 403 Olds yielded a double-groove power steering

pulley. I can drive the power steering pump from the crank, and then the

compressor from the pump. With 180 degrees of wrap for each belt, it should

work okay.

New plan for the AC belt. A 403 Olds yielded a double-groove power steering

pulley. I can drive the power steering pump from the crank, and then the

compressor from the pump. With 180 degrees of wrap for each belt, it should

work okay.

Getting started on the alternator bracket. 5/16" x 1" flat is bolted to the

head. It took a header bolt to clear the block on the inboard side.

Getting started on the alternator bracket. 5/16" x 1" flat is bolted to the

head. It took a header bolt to clear the block on the inboard side.

The power steering pump bracket got a tab welded on for the slotted alternator

bracket. I welded a tube in after welding the tab. One bolt goes through the

whole thing, including the alternator bracket.

The power steering pump bracket got a tab welded on for the slotted alternator

bracket. I welded a tube in after welding the tab. One bolt goes through the

whole thing, including the alternator bracket.

This is the finished bracket. It's as fully triangulated as I could come up

with. As you may have noticed from this page, I have a fetish about not

having important engine accessories fall off.

This is the finished bracket. It's as fully triangulated as I could come up

with. As you may have noticed from this page, I have a fetish about not

having important engine accessories fall off.

Bizarre-looking bracket prior to finish grinding and painting.

Bizarre-looking bracket prior to finish grinding and painting.

Another angle. Ugly, isn't it?

Another angle. Ugly, isn't it?

You can see how I've started porting the exhaust manifold to match the LT1

heads. It's upside down, of course, but you can see the raised and rounded

port roof coming in. I ground all the big knob for the air bung out after

welding up the hole.

You can see how I've started porting the exhaust manifold to match the LT1

heads. It's upside down, of course, but you can see the raised and rounded

port roof coming in. I ground all the big knob for the air bung out after

welding up the hole.

Backside of LH manifold. The two center ports are siamesed. As far as I can

tell, all of the manifolds of this type were made that way. I'd never paid

attention before. The proximity of the spark plugs cramps space for the

center runners, and the cylinders fire 360 degrees apart anyway, so it makes

little difference to power, though it causes the center two valves to run a

bit hotter.

Backside of LH manifold. The two center ports are siamesed. As far as I can

tell, all of the manifolds of this type were made that way. I'd never paid

attention before. The proximity of the spark plugs cramps space for the

center runners, and the cylinders fire 360 degrees apart anyway, so it makes

little difference to power, though it causes the center two valves to run a

bit hotter.

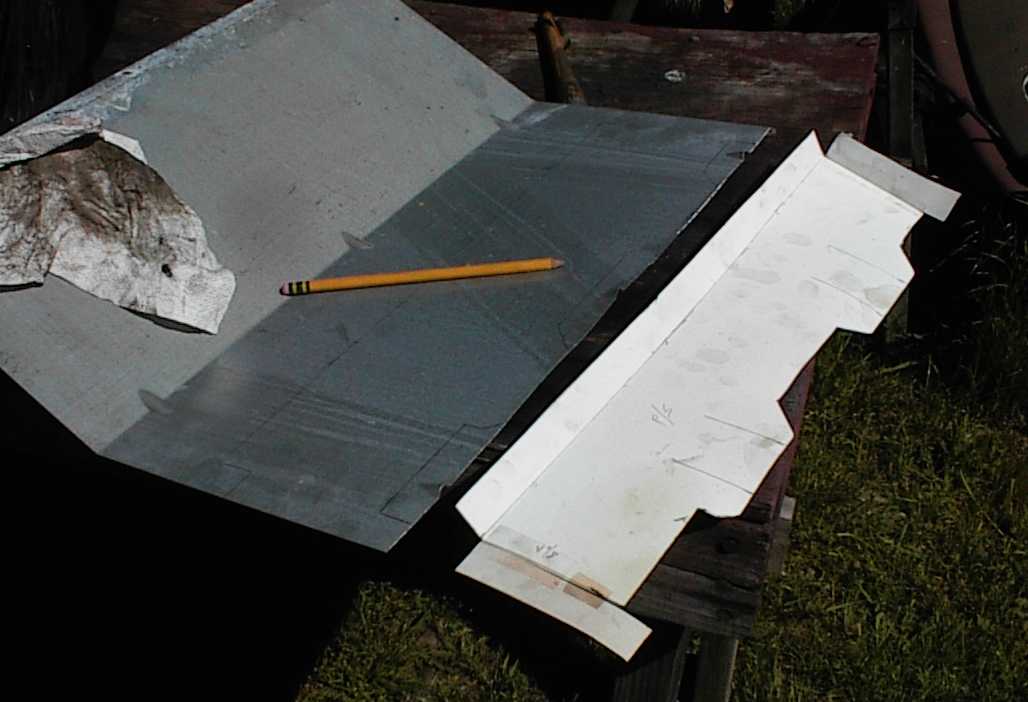

The upswept LT1 right hand exhaust nearly touches the valve cover. The

stainless steel OEM heat shield was enough to keep from cooking the gasket,

but since the ruined shield had to be removed, I made a simple box shaped heat

shield. This is the cardboard pattern and the piece of scrap steel sheet I

used.

The upswept LT1 right hand exhaust nearly touches the valve cover. The

stainless steel OEM heat shield was enough to keep from cooking the gasket,

but since the ruined shield had to be removed, I made a simple box shaped heat

shield. This is the cardboard pattern and the piece of scrap steel sheet I

used.

I traced the pattern onto the steel, cut it out with tin snips, and here I

have it clamped to a rectangular steel bar. I folded the corners with a

rubber mallet.

I traced the pattern onto the steel, cut it out with tin snips, and here I

have it clamped to a rectangular steel bar. I folded the corners with a

rubber mallet.

Here's the back panel. The tabs hanging down will get drilled for mounting

bolts.

Here's the back panel. The tabs hanging down will get drilled for mounting

bolts.

Tapping the thermostat adapter for the thermostat housing.

Tapping the thermostat adapter for the thermostat housing.