Author: Dave Williams; dlwilliams=aristotle=net

This engine went to England. It's a mild 350 street motor; single plane intake, 750 AFB, 9.3:1 compression, and moderate hydraulic cam. The heads are 882 castings with some fancy seat and valve work, and the valves are all ceramic thermal barrier coated. The engine is now coupled to a Renault transaxle in a trike. It's not on the road yet, but a recent (8/99) phone call revealed it likes British four-star leaded petrol just fine.

Here's the block - a nice four bolt part. My core supplier priced me a two

bolt block, but when he found he didn't have any on hand, he gave me this one

at the same price. For a mild street motor it makes no difference, but the

new owner will like it.

Here's the block - a nice four bolt part. My core supplier priced me a two

bolt block, but when he found he didn't have any on hand, he gave me this one

at the same price. For a mild street motor it makes no difference, but the

new owner will like it.

The block has already been bored, now it's being honed. I use a metal tank

(the farm supply store thought it was a horse feeder trough), a 3/4 HP low

speed drill, and a Sunnen Model N hone. The aluminum bar is an adjustable

stop to keep from running the stones into the main webs. You can see the

streams of honing oil coming down from the top of the picture; the one on the

left is a pressure bleed to keep the pump from shooting it all over the shop.

The block has already been bored, now it's being honed. I use a metal tank

(the farm supply store thought it was a horse feeder trough), a 3/4 HP low

speed drill, and a Sunnen Model N hone. The aluminum bar is an adjustable

stop to keep from running the stones into the main webs. You can see the

streams of honing oil coming down from the top of the picture; the one on the

left is a pressure bleed to keep the pump from shooting it all over the shop.

Assembling the short block. The flat top pistons will give around 9.3:1

compression.

Assembling the short block. The flat top pistons will give around 9.3:1

compression.

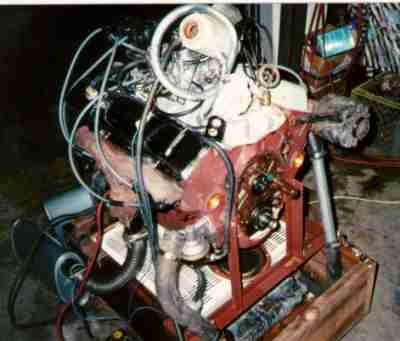

Nick wanted the engine run-in before shipment. I built this run stand

specifically for this job. Since then I've used it many times. Salvaged 2x10

boards from an old waterbed frame, some scrap angle iron from an old mobile

home frame, an old radiator I had in the shed, and a brand new $16 Wal-Mart

box fan. The radiator is underneath and the fan lays on top. Most run stands

put the radiator at one end, but this way I can get to both ends of the motor

without draining the water.

Nick wanted the engine run-in before shipment. I built this run stand

specifically for this job. Since then I've used it many times. Salvaged 2x10

boards from an old waterbed frame, some scrap angle iron from an old mobile

home frame, an old radiator I had in the shed, and a brand new $16 Wal-Mart

box fan. The radiator is underneath and the fan lays on top. Most run stands

put the radiator at one end, but this way I can get to both ends of the motor

without draining the water.

The engine started instantly, but oil pressure stayed at 10psi or so. After

much head-scratching and looking at the oil gallery drawings in the manuals, I

pulled the timing chain cover and timing chain. Whoops! The moron who put

the oil plugs in (surely it couldn't have been me at 3 AM) forgot the three in

the front, causing a major internal oil leak. Driving new plugs in fixed

*that* problem...

The engine started instantly, but oil pressure stayed at 10psi or so. After

much head-scratching and looking at the oil gallery drawings in the manuals, I

pulled the timing chain cover and timing chain. Whoops! The moron who put

the oil plugs in (surely it couldn't have been me at 3 AM) forgot the three in

the front, causing a major internal oil leak. Driving new plugs in fixed

*that* problem...

...but now, every time the engine started, it blew the oil filter off, with

results that would have been amusing on a Three Stooges re-run. This time I

pulled the pan off (if I'd made the legs on the brackets a little longer I

wouldn't have had to lift the engine from the run stand) and pulled the pump.

The plunger in the bypass valve was jammed so solidly I couldn't free it with

a punch. I replaced it with the cover from another pump, reassembled, and

got 65psi at hot idle.

...but now, every time the engine started, it blew the oil filter off, with

results that would have been amusing on a Three Stooges re-run. This time I

pulled the pan off (if I'd made the legs on the brackets a little longer I

wouldn't have had to lift the engine from the run stand) and pulled the pump.

The plunger in the bypass valve was jammed so solidly I couldn't free it with

a punch. I replaced it with the cover from another pump, reassembled, and

got 65psi at hot idle.

This is about 5 AM. It's almost dawn. The smoke is from all the oil burning

off the exhaust pipes. Remember blowing the filters off? There was oil all

over. I ran the engine for several hours, stopping for an oil change and to

retorque the heads, adjust the valves with it running, set the idle mix,

ignition timing, etc. For a modest engine, that sucker sure sounded good!

Sort of a crisp lopey idle.

This is about 5 AM. It's almost dawn. The smoke is from all the oil burning

off the exhaust pipes. Remember blowing the filters off? There was oil all

over. I ran the engine for several hours, stopping for an oil change and to

retorque the heads, adjust the valves with it running, set the idle mix,

ignition timing, etc. For a modest engine, that sucker sure sounded good!

Sort of a crisp lopey idle.

Boxing it up. I built the framework with the engine still on the stand to

make it easier. New water pump and fuel pump are visible - the water pump is

bolted down. Framework is held together with four inch long wood screws.

Boxing it up. I built the framework with the engine still on the stand to

make it easier. New water pump and fuel pump are visible - the water pump is

bolted down. Framework is held together with four inch long wood screws.

Flexplate goes on this side. Balancer *just barely* cleared. Most plug wires

were left on; it needed to be as close to ready-to-run as possible. Tape

labels on wires just in case. The ugly color is several coats of Rust-Oleum

Rusty Metal Primer; the chassis builder will repaint it with the spray gun

when he paints the trike.

Flexplate goes on this side. Balancer *just barely* cleared. Most plug wires

were left on; it needed to be as close to ready-to-run as possible. Tape

labels on wires just in case. The ugly color is several coats of Rust-Oleum

Rusty Metal Primer; the chassis builder will repaint it with the spray gun

when he paints the trike.

I lifted the box into the back of the truck and finished it there. The top

was 1/4" ply and the sides were veneer wall paneling. Every ounce counts when

you're air freighting something from Little Rock to London!

I lifted the box into the back of the truck and finished it there. The top

was 1/4" ply and the sides were veneer wall paneling. Every ounce counts when

you're air freighting something from Little Rock to London!

===========================================================================

350 Chevy

completed 06/16/98

engine run-in and retorqued before shipment

complete engine except for pulleys

COMPONENTS ---------------------------------------------------------------

crankshaft:

Chevy 350, cast

mains - STANDARD

rods - STANDARD

balanced

journals polished

pistons:

Federal Mogul 350 Chevy, .030 over

flat top with four reliefs

4.030 diameter

TLML moly coated sides

CBC-2 ceramic coated tops

rings:

standard small block Chevy. 4.030, Hastings

side clearance .003 top and second

ring gaps .014 top, .013 second, .019 oil

rods:

found 8 matching rods from several different sets

bearings STANDARD

TLML moly coated

rod side clearances .012

resized big ends (minimum size)

block:

early type 350, four bolt, two piece rear main

bored .030

honed to .003 piston/wall clearance

2 piece rear main seal (blue silicone around edges)

new core plugs (blue silicone sealer)

new cam bearings (Clevite 77) (coated)

all threaded holes chased

heads:

"882" for '70s 400 CID, open chamber

O-ring valve stem seals

surfaced flat

exhaust rotators

1.94/1.50 valves

3-angle valve job (stock is 1-angle), vacuum checked

new bronze guides

exhaust valves ceramic coated heads, moly coated stems

new Competition Products valve springs, 220# open

intake valves back cut 15 degrees

exhaust valves TLML and CBC-2 coated

stock 1.5:1 rockers

timing set:

stock type silent chain

cam:

Elgin E-1166-P

lobe lift .302 int/.320 exh

valve lift .453 int/.480 exh (1.5 rockers)

lobe center 112 (straight up)

advertised duration 282/294

.050 duration 216/228

advertised timing 28 BTC 74 ABC 78 BBC 36 ATC

.050 timing -4 BTC 40 ABC 46 BBC 2 ATC

moly grease used for assembly lube

Competition Products anti-pump-up hydraulic lifters

stock pushrods

induction:

Carter AFB, 750 CFM

Edelbrock Torker II intake manifold

note: .060 aluminum spacer between carb/manifold gaskets for proper

air seal - Edelbrock's "skeletonized" carb mounting pad will

usually have a vacuum leak otherwise

oiling:

new Speed-Pro high volume, high pressure pump

Melling pump cover with anti-chatter grooves

steel pump to drive rod bushing

ignition:

Chevrolet HEI

moly coated distributor gear

end play shimmed to minimum spec

new cap and rotor

new plug wires

plugs gapped to .050

water pump:

standard "long" replacement, rebuilt

starter:

standard Chevrolet, new brushes

fuel pump:

new, standard mechanical

miscellaneous:

Delco chrome valve covers

Delco dipstick assembly

chrome water neck, timing cover, timing tab - used - no charge

valve cover load spreaders - used - no charge

14" auto trans flexplate

8" damper (large OD) (3/8" fine thread bolts)

===========================================================================