Pontiac Lore

This page: www.bacomatic.org/~dw/pontiac/pontiac.htm

Main page: http://www.bacomatic.org/~dw/index.htm

Last Updated: 16 Jul 2003

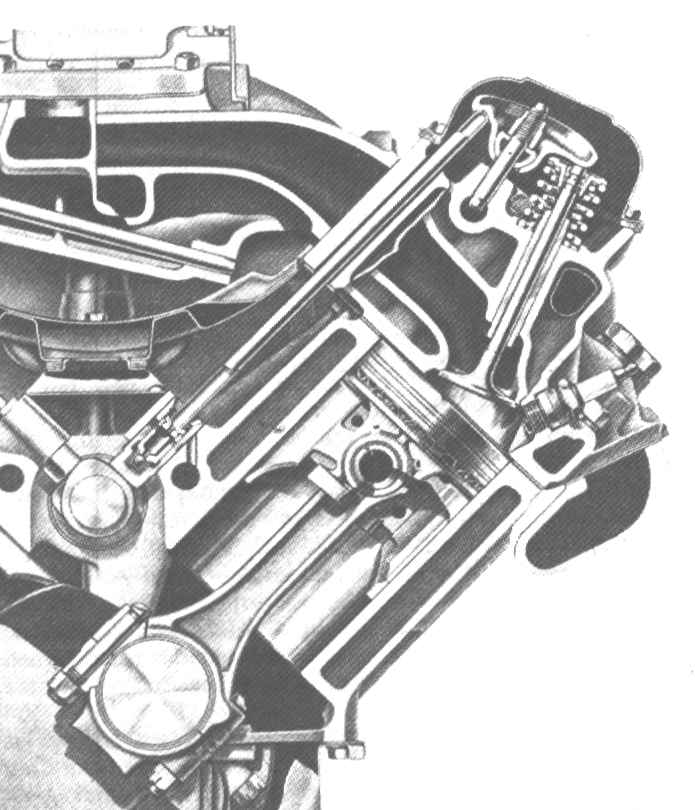

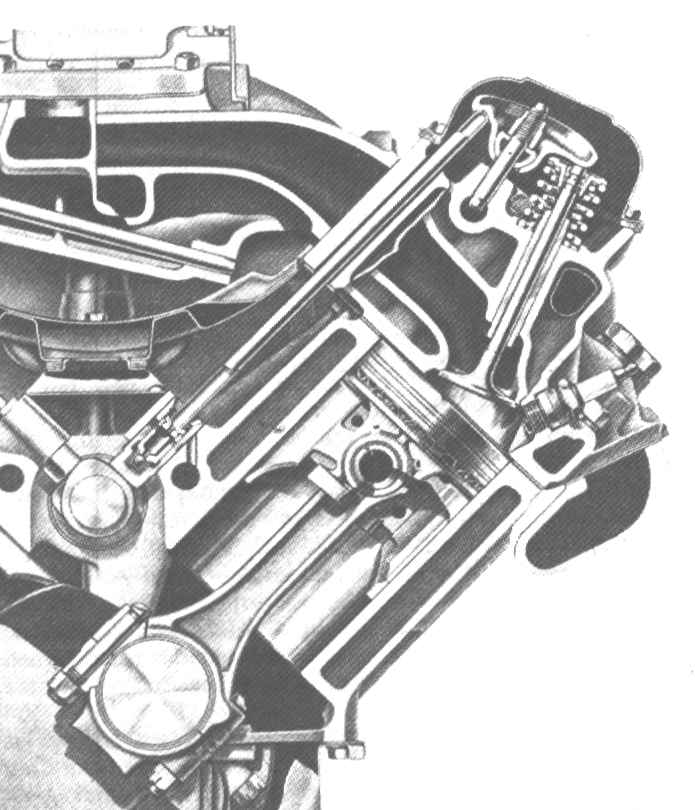

Cutaway of 1955 Pontiac 287. This engine was also available for several years

in GMC pickup trucks. Note the full-length water jackets to keep oil

temperature down, hollow rocker studs pressed into an oil gallery, and stamped

steel rockers. The stamped rockers were the brainchild of Pontiac engineer

Loren Papenguth and they came out on the 1955 Pontiac and the 1955 Chevrolet

V8s. The mass media usually (incorrectly) credit Chevrolet with the stamped

rocker. Pontiac's engineers were leery of oiling through the pushrods, so the

hollow pushrods ran dry and the rockers were oiled through hollow studs.

Later engined oiled through the pushrods.

This cutaway also shows the compact combustion chamber with lots of quench

and the internal steel water manifold, visible in the water jacket just under

the valve spring.

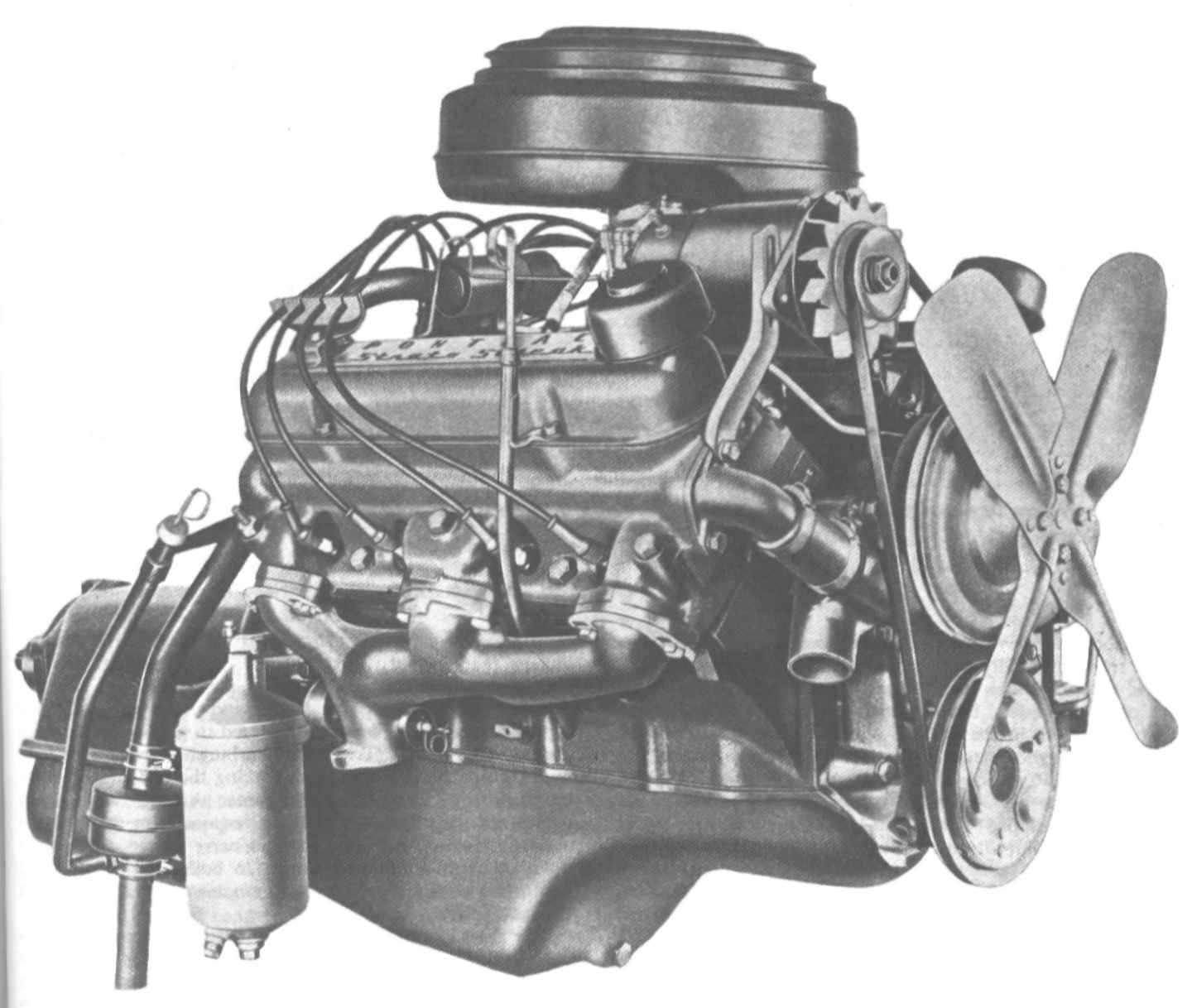

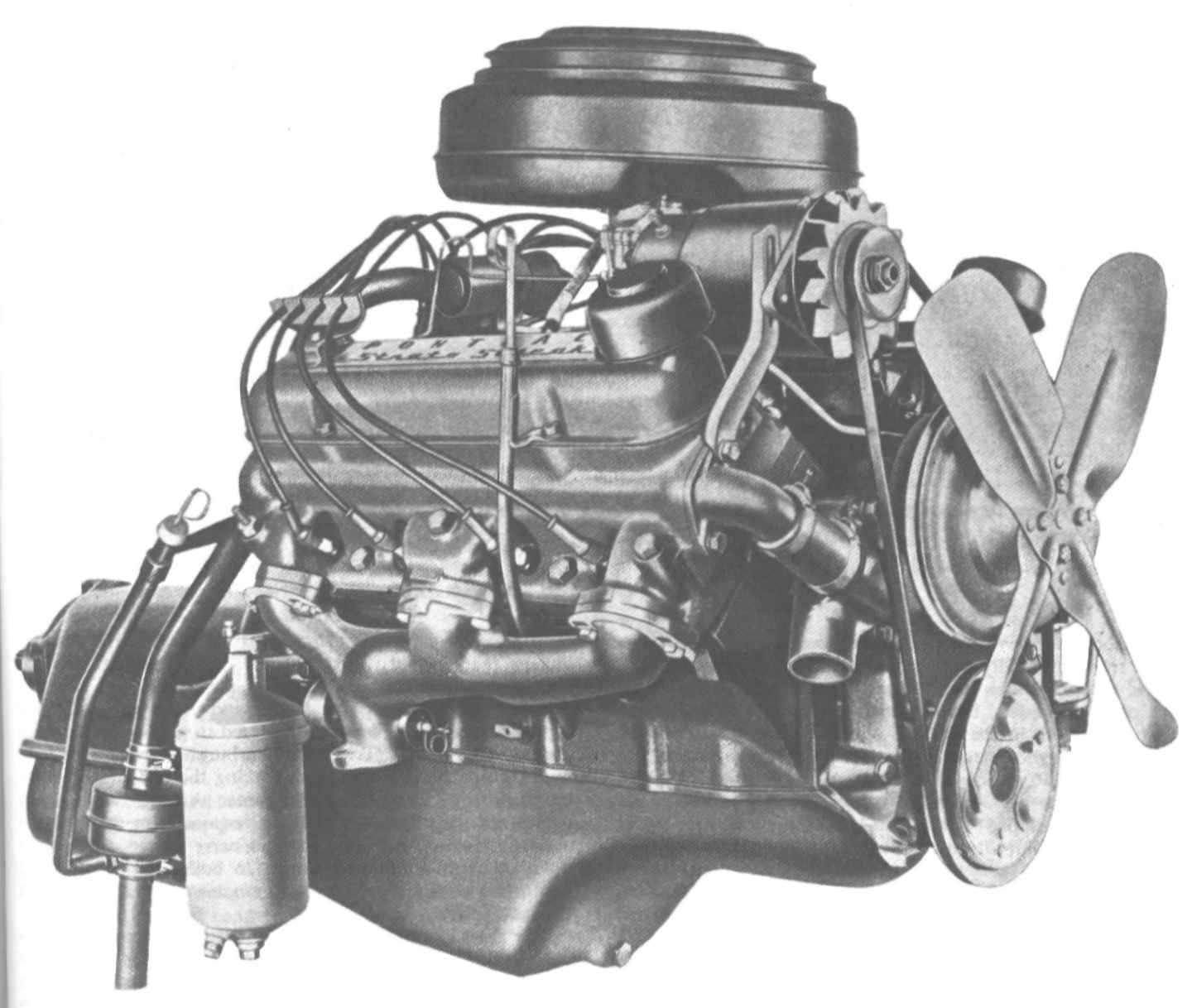

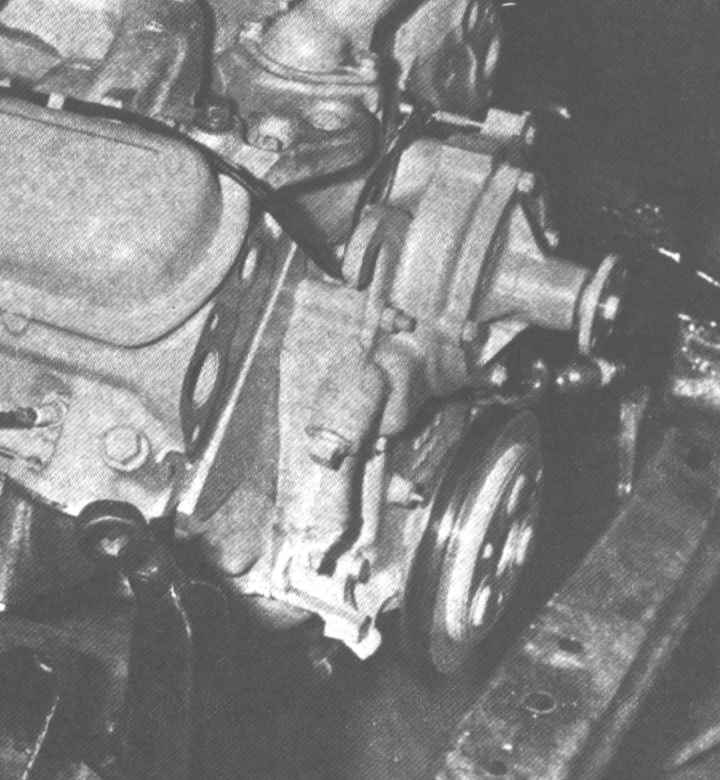

Here's an outside shot of the 1955 "Strato-Streak" 287. It made 180hp at 4600

RPM. Note the generator tucked up on the intake manifold with short, stout

brackets, the large oil filter canister with drain plug, and the water outlets

from the water pump going directly into the heads. The water feeds the

internal water manifolds visible in the previous image. A 1961 article by

Roger Huntington said,

"The new Pontiac engine also featured a special cooling layout that jetted

water onto the inner combustion chamber walls, above the exhaust valves, from

a steel tube inserted into the head castings. A high-capacity water pump put

almost twice as much water through the heads as went through the radiator

(through a by-pass system), this maintaining more even temperature through the

engine."

This is the same setup as is described in the infamous Evans "reverse flow"

patents and in the "innovative" Chevrolet LT-1 engine. As you can see, it's

not only very old technology, but even General Motors appeared to have

forgotten that Pontiac did it first.

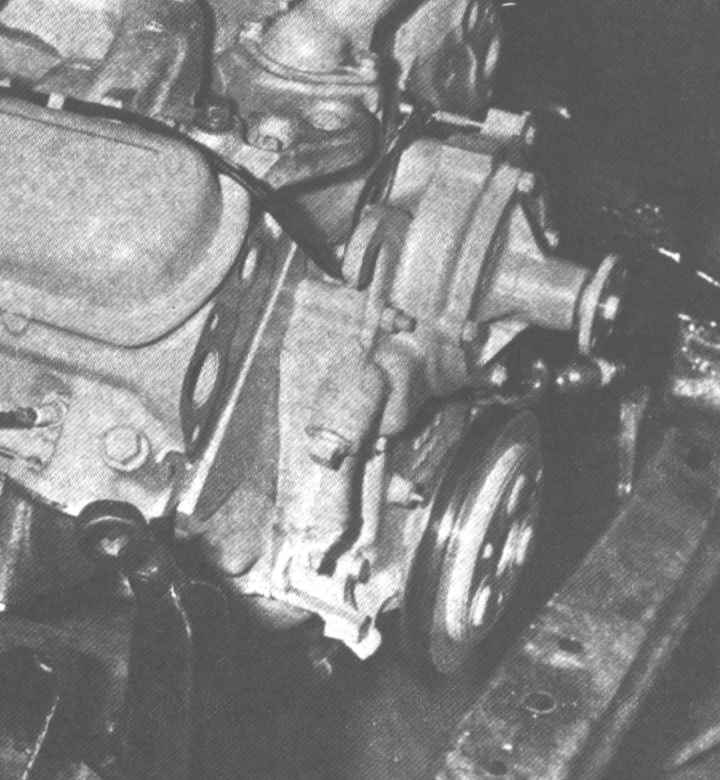

The Pontiac V8 was enlarged quickly. The '56 317 and '57 347 were externally

identical to the '55 model. I don't have any specific sources for the '58 347

or '59-'60 389 engines, but as you can see here by '61 the reverse flow

cooling had been dropped. The generator isn't on this engine, but it was on

top in '58 and hung out alongside the valve cover in '59. I'd *guess* the

reverse flow cooling was dropped in '58. Note the cylinder heads still have

provision for reverse flow cooling; the holes are filled with freeze plugs.

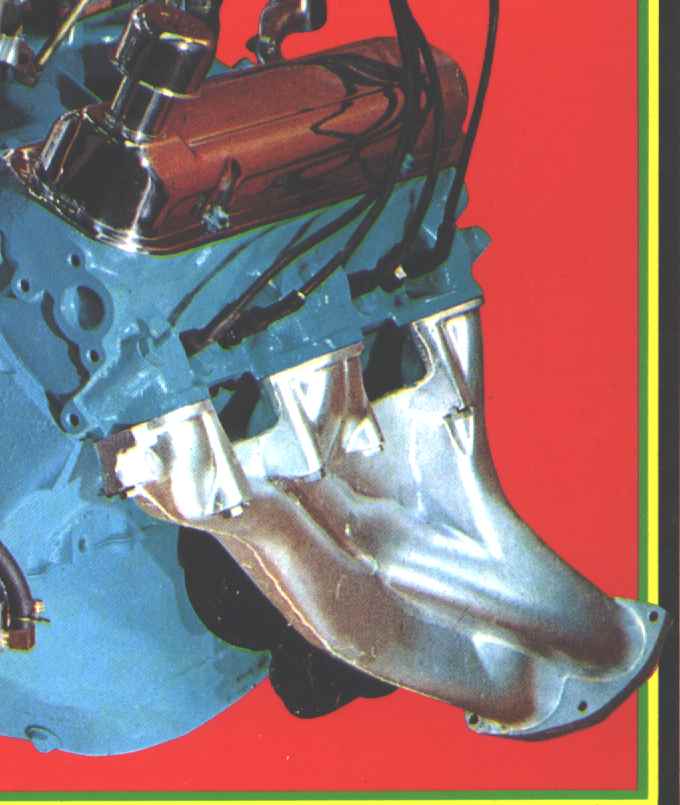

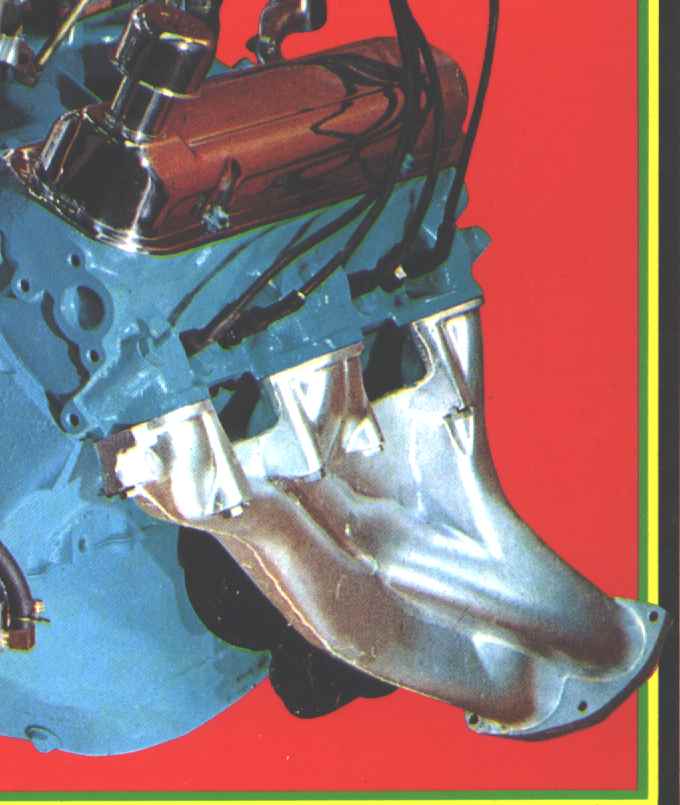

I'm happy to have found such a nice image of this particular part - it's a

cast aluminum header from an early '60s 421 Pontiac. A lot of people refused

to believe such a thing ever existed. Yes, there were erosion problems, and

the old timers say the cars would drip molten aluminum on the ground after a

lean pass. These are aluminum variants of the iron headers, which weighed

around 80 pounds.

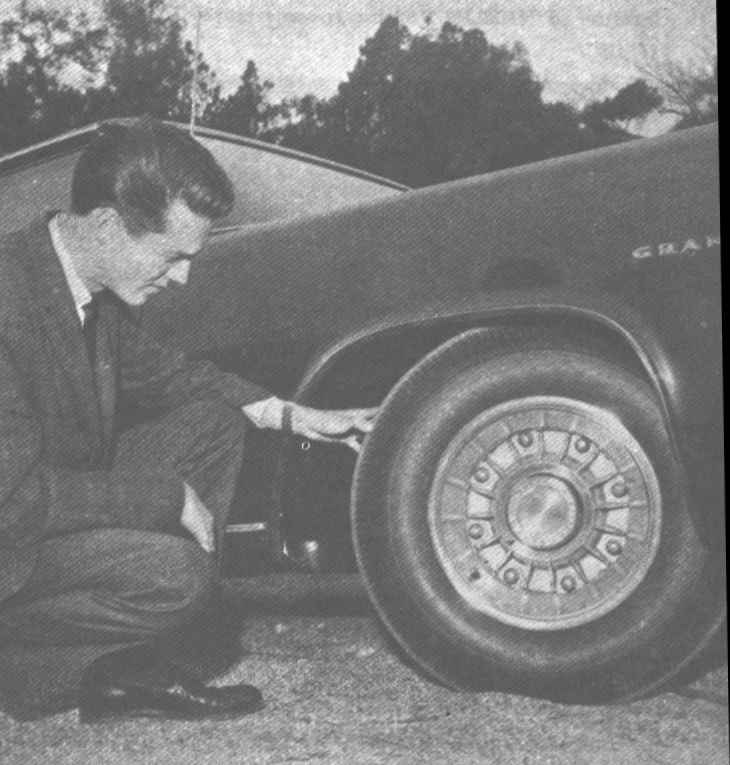

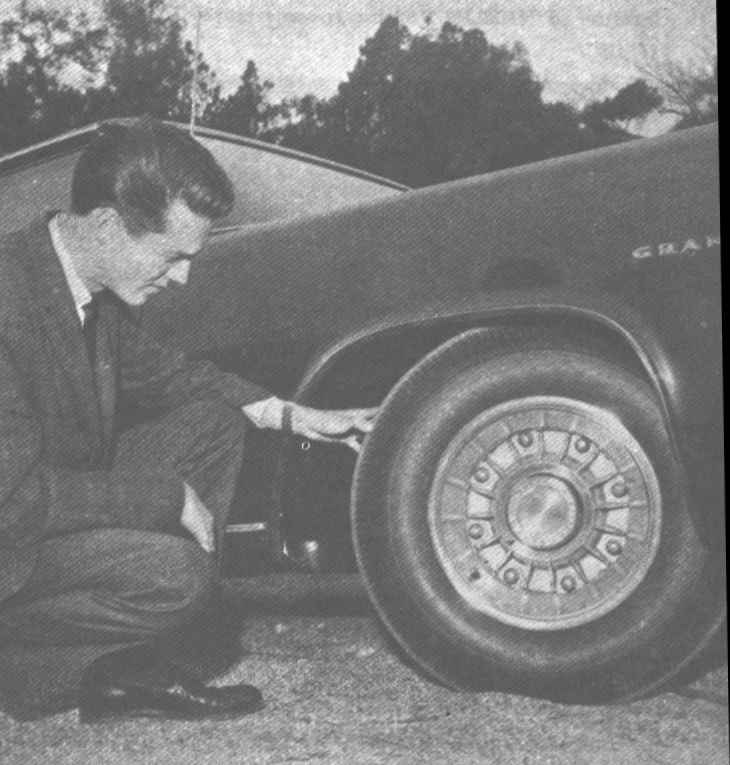

Early-mid '60s full size Pontiacs could be ordered with the optional "heavy

duty" brake package. This consisted of a hoop-type 15" wheel similar to that

of an early VW; just a rim with some lugs on the inside. The "aluminum wheel"

is actually a huge finned brake drum! There is no wheel visible in this

image, just the brake drum and a snap-on trim ring.

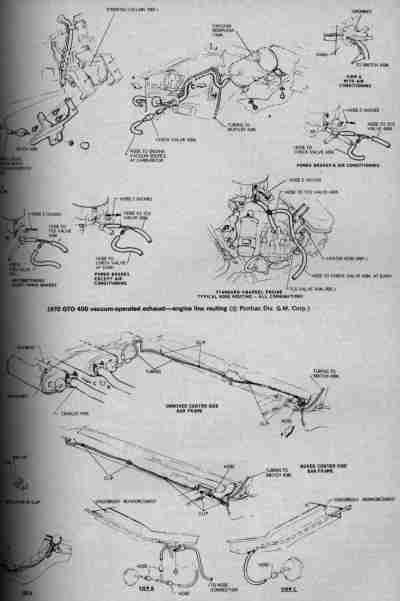

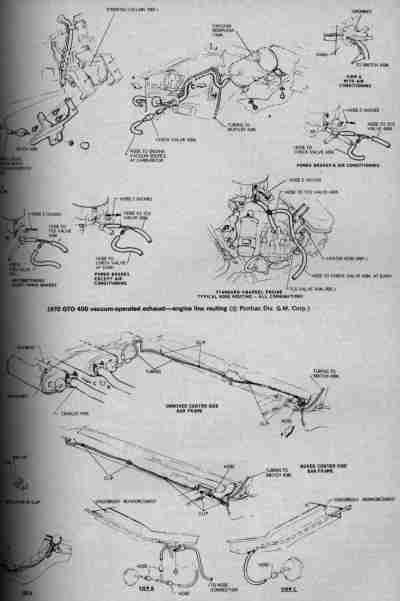

1970 GTO 400 vacuum-operated exhaust. No, Mitsubishi was not the first to

have a "back pressure control" flapper in muffler. More forgotten Pontiac

innovation.