TRX' Fuel Surge Tank

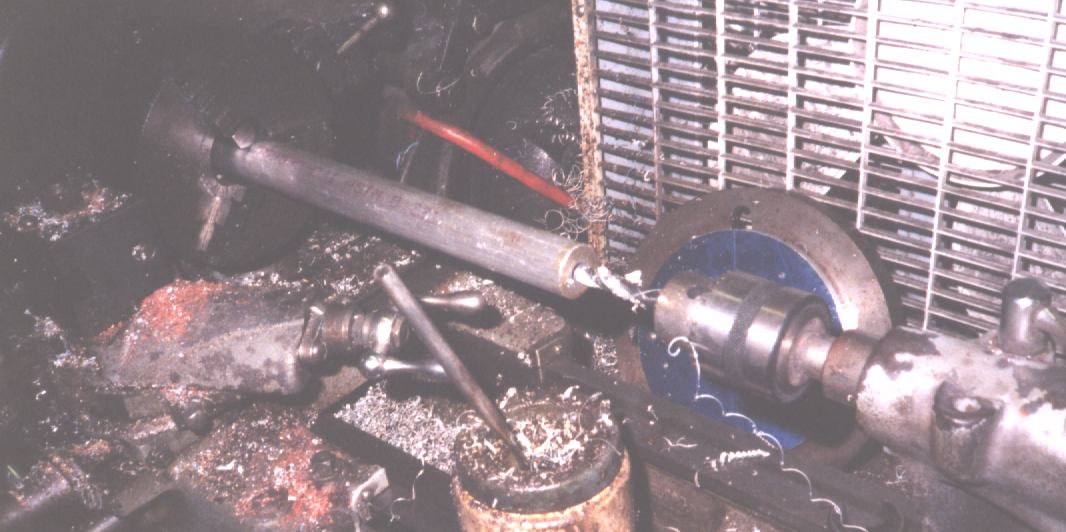

This is the fuel surge tank for Tyrannosaurus RX. A 6 PSI inline pump near

the tank will keep this tank full of fuel; a smaller return line runs overflow

back to the main fuel tank. A 155 lph high pressure pump gets mounted in this

tank, which will have short -6AN braided steel lines connecting it to the fuel

rail and fuel pressure regulator. I've seen too many EFI cars burned down to

the ground to trust rubber hoses or push-on fittings at 45 PSI.

Here's the 3.5" aluminum tank, the 2.5" baffle (note spiral holes to break up

any bubbles in the returned fuel), press-fit counterbored bottom cap and top

ring, and round top cover. Everything except the cover is TIGged together.

Then the radial fuel inlets and outlets get welded on.

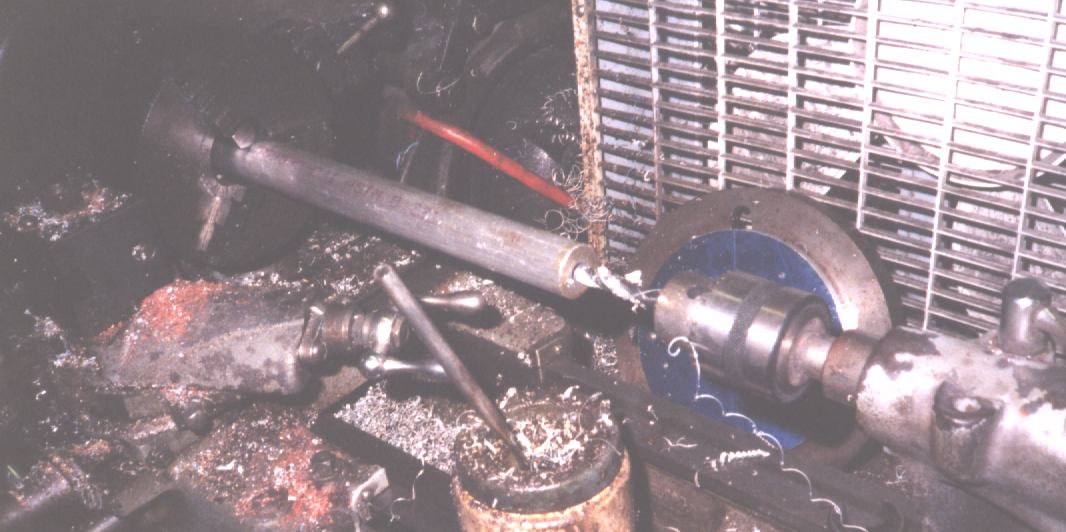

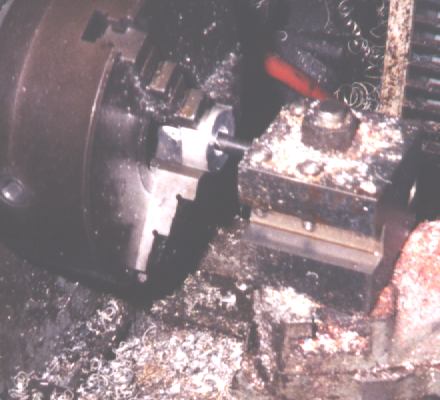

Drilling a piece of 1" 6061-T6 round bar. For one of the radial inlets. Yes,

its' hung out there a long ways, but it's not a deep hole and it was deeply

center punched. Even if it wanders a little to the side it won't matter much.

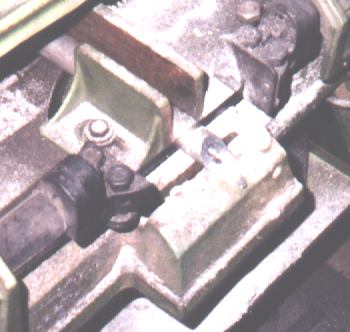

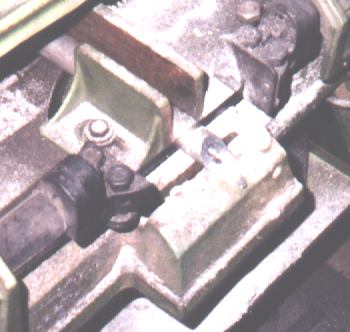

Setting up the boring head. The diameter is set to the same as the OD of the

piece of tubing I'm using for the surge tank.

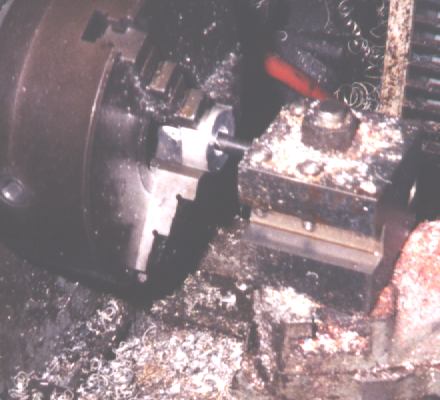

Here I am flycutting the bar.

Now I'm whacking it off with the band saw, with a little left on the end for

facing off in the lathe. The fitting looks sort of like one of those patent

nose pair removal tools, doesn't it?

Now I'm boring the hole a little larger before chamfering, running the taper

reamer in, and tapping 3/8 NPT.

=====================================================

01/00 - the main tank is welded up, the radial fittings are done, there's a

big pile of AN fittings, a pump, etc. I need to make the nylon bushings to

pass the wiring through to the pump, make a bracket to hold the pump in place,

and weld on the radial fittings. Just a simple matter of round tuits now.

I've already made the mounting bracketry, with nice rubber isolators.

=====================================================

Return to Dave Williams' home page: http://www.bacomatic.org/~dw/index.htm