Internal Balancing A 347 Stroker Crank

This is one of those TFS forged cranks, 3.4" stroke, for bringing a 289, 302,

or 5.0 out to 347 inches. The owner had a set of 5.4" rods and matching

pistons to go with it. No big deal, normally, but he wanted it internally

balanced. We discussed the project at length; you can't tell if a crank will

make it or not until it's done. It was possible I'd get it almost there, but

not quite, and we'd either have to remove weight to get it back to 28oz or

balance the flywheel to some bastard weight to match the crank. It also

wasn't possible to figure out how long it would take beforehand; I'd never

done one before. It turned into one of those "never again" nightmare jobs

that stretched out over almost a year of spare time.

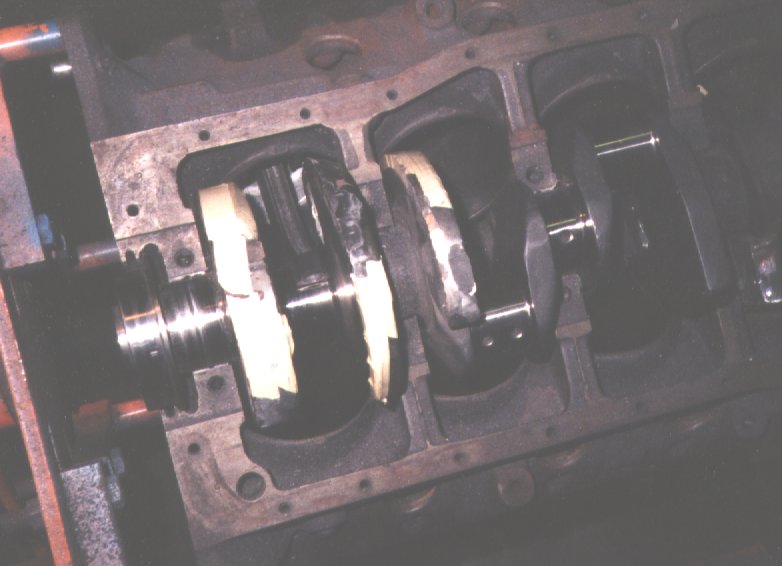

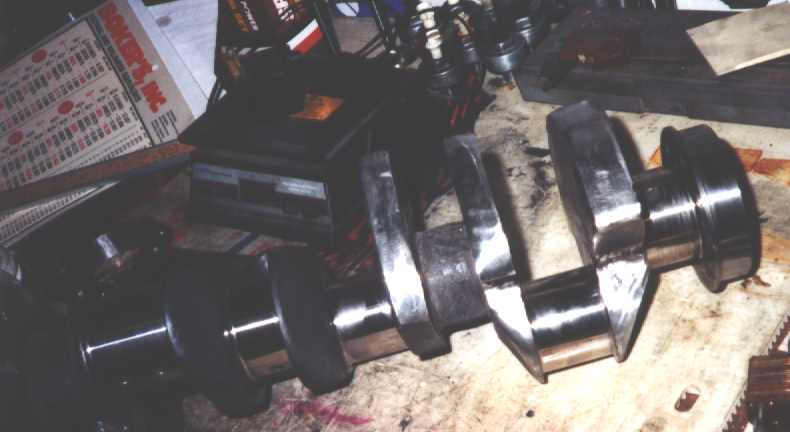

Here I've started by welding some steel bits to the outside of the crank. You

have to start somewhere, and adding metal is lots simpler and cheaper than

going straight to the heavy metal.

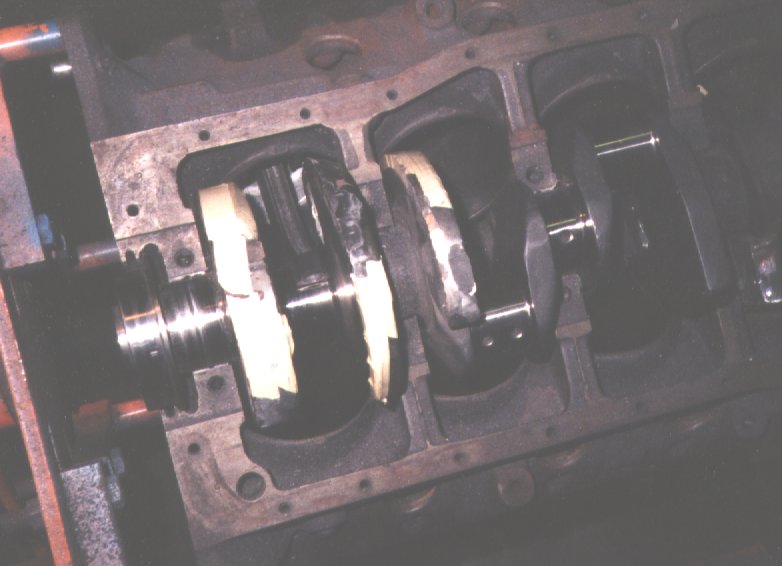

Now for clearancing the welded-on bits to the block. The same thing also has

to be done for the bottoms of the pistons at BDC. It's tedious, dirty work.

Now I've started adding heavy metal. I had some 1/2" heavy metal bar

available. Unfortunately, the crankshaft is of heat treated 4150 steel;

regular still bits simply slide off. I had to borrow the use of a heavier

drill press and buy a $55 carbide bit to make any headway in the stuff. Each

hole, about 1-1/2" deep, took about half an hour to drill. A file will slide

right over one of the counterweights without even messing the finish. I had

no clue; if I'd checked this to start with, I would've put the thing right

back in the box and mailed it back without touching it. As it was, I'd

already started...

The three shots above show the finished product. The outside diameters of all

the counterweights have been built up to within .050 of the block or pistons;

the weird bevels are what resulted. There's a fair amount of heavy metal in

there as well. These shots show the contours better than the 'trophy shots'

below.

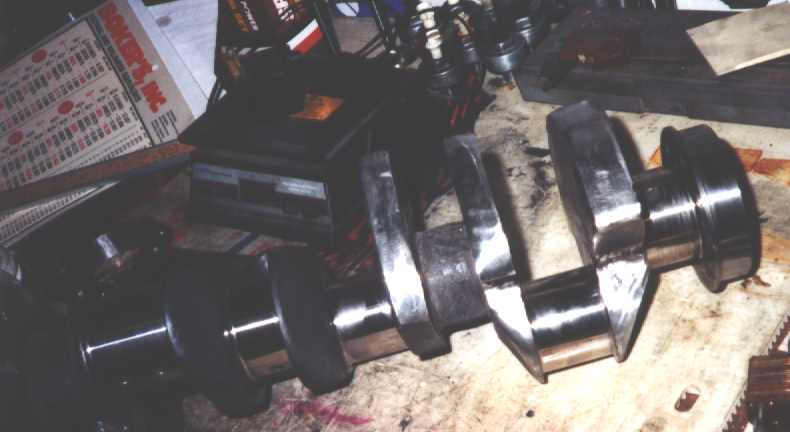

This set of views is the 347 crank vs. a 289 crank. It's not really a fair

comparison since the 289 crank is destroked to 2.75" and has been cut down to

a little over 5" on the counterweight OD, but it was the closest thing to a

stock crank I had on hand. The TFS crank is as large as will physically fit

in a 302 block.

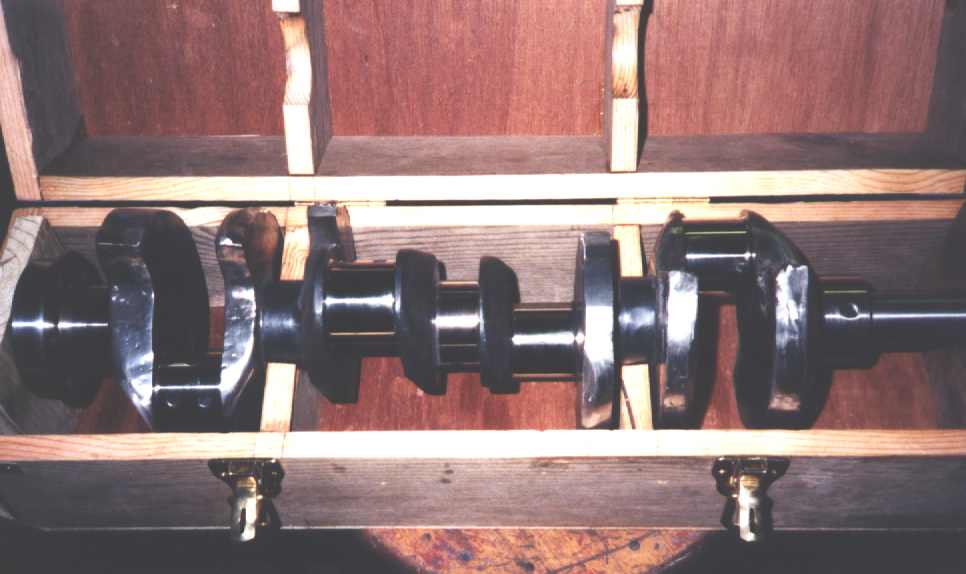

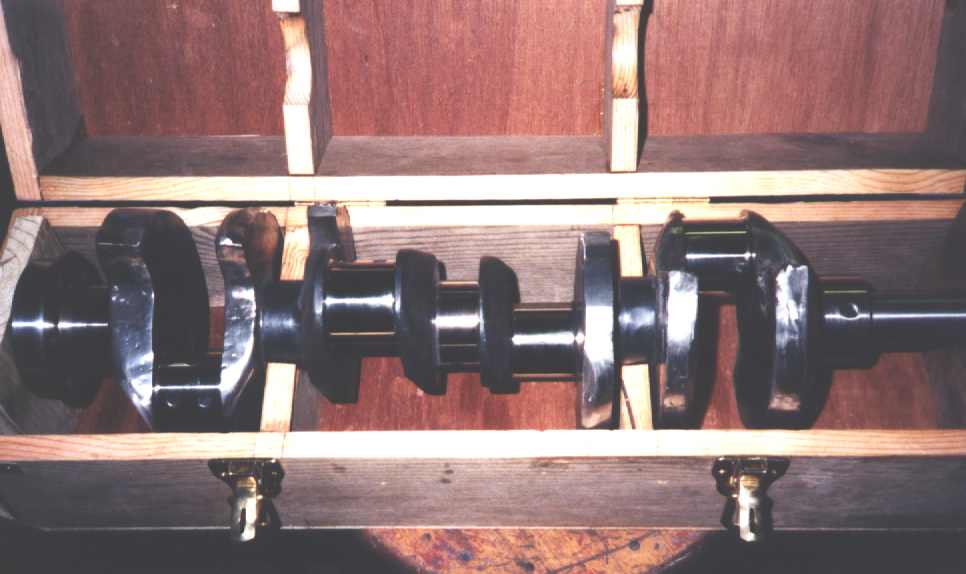

All boxed up and ready to return to its owner.