Author: Dave Williams; dlwilliams=aristotle=net

We've already done a rebuild on the original 283 for Tommy's '65 Impala SS. Then we did a thumping 311 inch 283 stroker. Now he has a 383 stroker, for a hundred cubes more than he started with...

Here we begin - a crusty old 350 from a 1975 Chevy van. One of the last of

the heavy blocks before GM started their weight loss program.

Here we begin - a crusty old 350 from a 1975 Chevy van. One of the last of

the heavy blocks before GM started their weight loss program.

The engine was essentially complete, with the original intake and 6-quart

truck pan, which will be used in the subsequent buildup.

The engine was essentially complete, with the original intake and 6-quart

truck pan, which will be used in the subsequent buildup.

This particular engine had essentially died of old age. The previous owner

had changed the oil every now and then, so it wasn't the slimer it could have

been.

This particular engine had essentially died of old age. The previous owner

had changed the oil every now and then, so it wasn't the slimer it could have

been.

After everything unbolts, you get to drive the cam bearings out and then

remove the freeze plugs. Typically, about half the plugs will come right out,

and the rest will require much hammering, pliering, chiseling, and cursing.

After everything unbolts, you get to drive the cam bearings out and then

remove the freeze plugs. Typically, about half the plugs will come right out,

and the rest will require much hammering, pliering, chiseling, and cursing.

Once the freeze plugs are out, you can tilt it on its nose and run a 3/8"

drill through the square head oil plugs in the back. You can play with the

torch, wax, penetrating oil, square head impact bits, and other tools, but

they'll take longer, and about half the time you'll wind up drilling the

[deleted] plugs out anyway.

Once the freeze plugs are out, you can tilt it on its nose and run a 3/8"

drill through the square head oil plugs in the back. You can play with the

torch, wax, penetrating oil, square head impact bits, and other tools, but

they'll take longer, and about half the time you'll wind up drilling the

[deleted] plugs out anyway.

Hammer a cape chisel into the drilled hole, turn with wrench. EZ-outs of

various sorts will just wedge the tapered pipe plugs immovably into their

holes.

Hammer a cape chisel into the drilled hole, turn with wrench. EZ-outs of

various sorts will just wedge the tapered pipe plugs immovably into their

holes.

Three foot long, 5/16" steel rod pops the front oil plugs out from the back.

Now the block goes into the tank for its first cleaning.

Three foot long, 5/16" steel rod pops the front oil plugs out from the back.

Now the block goes into the tank for its first cleaning.

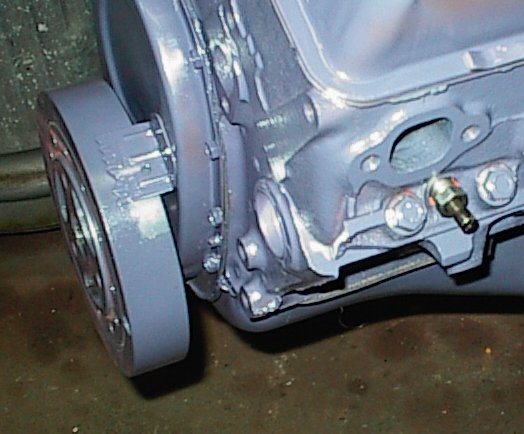

The much cleaner block with the brand new 3.75" stroker crank. The pan rails

and cylinder skirts are ground to provide .060" clearance for the rod bolts.

The much cleaner block with the brand new 3.75" stroker crank. The pan rails

and cylinder skirts are ground to provide .060" clearance for the rod bolts.

The block had to be align bored, which isn't very common for a Chevy. I guess

it had seen a hard life. All the naughty bits got cleaned up and balanced

afterward.

Since this is a truck motor that will get run hard on cheap gas, it got a

short fill of Hard Blok to stabilize the bores.

Since this is a truck motor that will get run hard on cheap gas, it got a

short fill of Hard Blok to stabilize the bores.

Another view of the block filler. The trick is to mix it liquid enough to

pour through a large mouth funnel; the first few times I used it, I didn't use

enough water.

Another view of the block filler. The trick is to mix it liquid enough to

pour through a large mouth funnel; the first few times I used it, I didn't use

enough water.

The buyer wanted new rod bolts. The ARP bolts only cost a few bucks more than

stock replacements.

The buyer wanted new rod bolts. The ARP bolts only cost a few bucks more than

stock replacements.

Resized rod, new piston, rings are already gapped, bearing clearances checked.

We're ready to rock and roll now.

Resized rod, new piston, rings are already gapped, bearing clearances checked.

We're ready to rock and roll now.

And shortly after, all right pistons are in. Quench side is to the intake

manifold. These are 8.5:1 pistons. For a few per cent peak power loss, the

lower CR will make it much easier to tune and more tolerant of bad gas, hot

weather, or hard going pulling a trailer through the mountains.

And shortly after, all right pistons are in. Quench side is to the intake

manifold. These are 8.5:1 pistons. For a few per cent peak power loss, the

lower CR will make it much easier to tune and more tolerant of bad gas, hot

weather, or hard going pulling a trailer through the mountains.

Cam degreeing time again.

Cam degreeing time again.

Offset bushing kit. The 4 degree bushing is the one I wanted.

Offset bushing kit. The 4 degree bushing is the one I wanted.

The dowel hole in the crank sprocket has to be enlarged to take the bushing.

The retaining bolt holes also have to be enlarged or slotted.

The dowel hole in the crank sprocket has to be enlarged to take the bushing.

The retaining bolt holes also have to be enlarged or slotted.

And here we are, with the cam advanced 4 degrees. The bolt lock plate is

necessary to keep the bushing from falling out. Chevy used them on 265s and

some 283s, but dropped the lock plates about the time the 350s came out. New

Grade 8 bolts came with the kit. I torqued them with Loctite 252 and bent the

locking tabs over.

And here we are, with the cam advanced 4 degrees. The bolt lock plate is

necessary to keep the bushing from falling out. Chevy used them on 265s and

some 283s, but dropped the lock plates about the time the 350s came out. New

Grade 8 bolts came with the kit. I torqued them with Loctite 252 and bent the

locking tabs over.

Now I screw the fancy adjustable piston stop in... it won't work with the deep

dishes in these pistons, so I had to dig out the extended stop I use for

Fords, which have a shallower plug angle. The crank is gently turned until

the piston contacts the stop.

Now I screw the fancy adjustable piston stop in... it won't work with the deep

dishes in these pistons, so I had to dig out the extended stop I use for

Fords, which have a shallower plug angle. The crank is gently turned until

the piston contacts the stop.

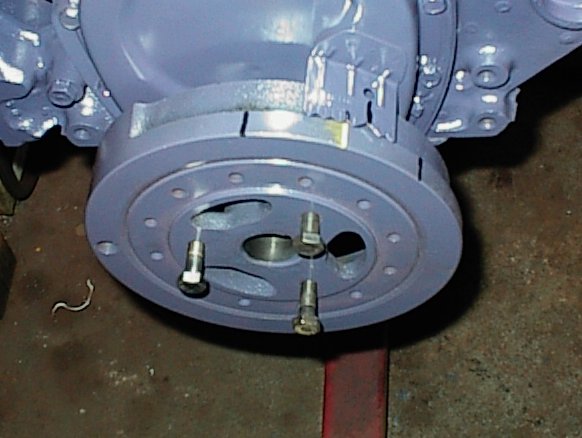

That's a brand new 400 balancer. There's a brand new 400 flexplate on the

other end.

We make a mark on the balancer, then turn the engine the other way until it

hits again.

We make a mark on the balancer, then turn the engine the other way until it

hits again.

Halfway between the two marks is Top Dead Center. This one was pretty close.

I filled the groove in the balancer with paint, and marked TDC and 8 Before on

the timing tab.

Halfway between the two marks is Top Dead Center. This one was pretty close.

I filled the groove in the balancer with paint, and marked TDC and 8 Before on

the timing tab.

This engine got brand new 1.6:1 rockers on the intake side. I used stock

1.5:1 rockers on the exhaust side. I always dress any dings or dimples off

with the disc sander. Anything more than a faint impression, easily sanded

off, goes into the metal recycling bucket.

This engine got brand new 1.6:1 rockers on the intake side. I used stock

1.5:1 rockers on the exhaust side. I always dress any dings or dimples off

with the disc sander. Anything more than a faint impression, easily sanded

off, goes into the metal recycling bucket.

Adjusting the valves. I had a Compact Flash chip decide to freak out and lost

all the pictures of the heads. These aren't the heads that came on the core

engine; they're a set of thickwall 993 open chamber heads that I had pocket

ported years ago for another engine, which was also a 383. They had come back

as trade-ins for another pair of more seriously ported heads. These got new

bronze guides, brand new 2.02/1.60 stainless steel valves and pocket rework to

accomodate them, got decked true on the head machine, Magnafluxed, three angle

valve job, new Z-28 290# valve springs, Perfect Circle seals, yadda yadda.

Adjusting the valves. I had a Compact Flash chip decide to freak out and lost

all the pictures of the heads. These aren't the heads that came on the core

engine; they're a set of thickwall 993 open chamber heads that I had pocket

ported years ago for another engine, which was also a 383. They had come back

as trade-ins for another pair of more seriously ported heads. These got new

bronze guides, brand new 2.02/1.60 stainless steel valves and pocket rework to

accomodate them, got decked true on the head machine, Magnafluxed, three angle

valve job, new Z-28 290# valve springs, Perfect Circle seals, yadda yadda.

This is the oil filter bypass for a small block Chevy. Its stated purpose is

to open and allow oil to circulate if the filter gets completely stopped up.

It has a very weak spring, which lets unfiltered oil bypass the filter when

the engine is running. I knocked the spring and disc valve out and used a

3/8" NPT pipe tap in the hole.

This is the oil filter bypass for a small block Chevy. Its stated purpose is

to open and allow oil to circulate if the filter gets completely stopped up.

It has a very weak spring, which lets unfiltered oil bypass the filter when

the engine is running. I knocked the spring and disc valve out and used a

3/8" NPT pipe tap in the hole.

Now a 3/8" hex head pipe plug and Loctite eliminate the bypass. This has

proven safe even in subzero weather as long as you're not running 50-wt

sludge. Theoretically, with thick enough oil, cold enough weather, and a

heavy foot, you could either blow the filter off the block or strain part of

the pump drive system, but I've never had it happen... and it makes me happy

to know *all* the oil getting to the filter is going through it instead of

around it. The rear main on the small Chevy runs unfiltered oil, a holdover

from the days before Chevy cobbled a filter onto the small block, which

originally had none. That's why there are so many strange turns in the oil

path of the small Chevy.

Now a 3/8" hex head pipe plug and Loctite eliminate the bypass. This has

proven safe even in subzero weather as long as you're not running 50-wt

sludge. Theoretically, with thick enough oil, cold enough weather, and a

heavy foot, you could either blow the filter off the block or strain part of

the pump drive system, but I've never had it happen... and it makes me happy

to know *all* the oil getting to the filter is going through it instead of

around it. The rear main on the small Chevy runs unfiltered oil, a holdover

from the days before Chevy cobbled a filter onto the small block, which

originally had none. That's why there are so many strange turns in the oil

path of the small Chevy.

Melling M55HV high volume pump.

Melling M55HV high volume pump.

The new pickup tube being driven on with my homemade tool. Beats the heck out

of trying to do it with a chisel or screwdriver.

The new pickup tube being driven on with my homemade tool. Beats the heck out

of trying to do it with a chisel or screwdriver.

Another shot of the tool.

Another shot of the tool.

Now we clay the pickup and trial fit the pan.

Now we clay the pickup and trial fit the pan.

When the pan comes off, the smashed clay gives us the pickup clearance. We

were right at the recommended 3/8", so I didn't have to tap the pickup up or

down to adjust it.

When the pan comes off, the smashed clay gives us the pickup clearance. We

were right at the recommended 3/8", so I didn't have to tap the pickup up or

down to adjust it.

And the pan goes on for real... the assembled engine gets a final coat of

Dupli-Color Plum Purple when it's done. The purple was a joke on the buyer,

but most of the people who saw it liked it.

And the pan goes on for real... the assembled engine gets a final coat of

Dupli-Color Plum Purple when it's done. The purple was a joke on the buyer,

but most of the people who saw it liked it.

Fired up first try, spent two hours on the run stand, cool as a cucumber. The

214/214 cam is dead smooth in an 8.5:1 383. The oil came out clean, it's

ready to ship.

Fired up first try, spent two hours on the run stand, cool as a cucumber. The

214/214 cam is dead smooth in an 8.5:1 383. The oil came out clean, it's

ready to ship.

M A X I M U M O V E R D R I V E R A C I N G E N G I N E S

383 Chevy stroker for Tommy Wilson

completed 04/03/2003 (complete engine)

4.060 bore (+.060)

3.750 stroke (+.250)

388 CID, 6365cc (6.4 L)

72 cc combustion chambers

26 cc dished pistons

3 cc .015 deck

7.3 cc .035 gasket

------

108.3 cc clearance volume

796 cc swept volume

+ 108.3 cc clearance volume

--------

904.3 cc total volume

904.3/108.3 = 8.35:1 CR

warranty: if it breaks, you get to keep all the pieces you can find

heads:

993 heavy-wall castings

pocket ported

new 11/32 valve guides

SSI 2.02/1.60 one-piece stainless steel valves, single groove

3-angle valve job

chased all threaded holes

clearanced intake pushrod holes for 1.6 rockers

.080-.090 exhaust seats

.060-.070 intake seats

Perfect Circle seals and steel umbrellas (no O-rings)

.001-.0015" guide clearance

new Z/28 valve springs, 190# open

block:

350 Chevy, two bolt main

bored .060 over, honed #400

1/3 fill Hard Block

new cam bearings, Dura-Bond CH-8

new freeze plugs

clearance bores and pan rails for stroker crank

chase all threaded holes

align honed mains

new lower dipstick tube

pistons:

Dynagear 1383-P-60, .060-over

26cc D-shaped dish (checked)

no pin offset

1.43" pin height for 5.7" rod 383

rings:

Hastings 4.060", 5/64, 5/64, 7/64"

gaps:

1) .018 2) .016

.018 .016

.024/.032 .026/.026

3) .027 .018

.024 .019

.039/.037 .030/.030

5) .022 .021

.020 .023

.035/.037 .033/.032

7) .020 .017

.020 .017

.033/.032 .032/.031

rods:

stock Chevy 5.7" forgings

inboard corners beveled for cam clearance

ARP 134-6003 rod bolts

cam:

Elgin E1029

214/214 @.050, 112LC, .443 lift

installed 4 degrees advanced (offset bushing)

valvetrain:

new hydraulic lifters

1.6:1 intake rockers

1.5:1 exhaust rockers

Cloyes double roller timing set

stock pushrods

crank:

new 383 stroker casting, 3.75" stroke

std main bearings, Clevite MS-909-P; clearance .002-.0025"

std rod bearings, Clevite CB-663-P

rod journals .0005" under; clearance .0015-.002"

new Pioneer 400 harmonic balancer

new Pioneer 400 flexplate

balance:

external balance

new Pioneer 400 harmonic balancer, 8" diameter

new Pioneer 400 flexplate

413 rod big end

413 rod big end

55 rod bearing

55 rod bearing

703 piston with pin

59 rings

179 rod pin end

-----

1877 bob weight

setup RPM 800

balance RPM 650

front imbalance .05 oz-in

rear imbalance .06 oz-in

oiling:

Melling M55HV high volume

6-quart truck pan

misc:

stock iron Quadrajet intake manifold

paint Dupli-Color DE 1640 Plum Purple

stock Chevy valve covers with load spreaders

requires 1/8" hole in thermostat or heater bypass; bypass port in

block is covered by Hard Block.