Joe Weinstein's 410 Windsor

This page: www.bacomatic.org/~dw/wein410/wein410.htm

Main page: http://www.bacomatic.org/~dw/index.htm

Last Updated: 16 Jul 2003

Author: Dave Williams; dlwilliams=aristotle=net

Joe Weinstein wanted something with more oomph for his '86 Saleen Mustang.

He also lives in San Francisco and didn't want any hassle with the California

smog check system. Specificially, he not only wanted it to pass smog, but for

every part the C.A.R.B. was concerned with to be 100% California legal.

The 1993 Cobra R came with a 351W, so as far as the CARB was concerned it was

a legal retrofit. As far as the CARB is concerned, the casting number on the

block *is* the engine; therefore, we needed a block with a correct casting

number. However, the F150 pickup roller block was *not* a legal interchange;

it had to be a *Mustang* block, which meant it had to be a Cobra R block...

and the Cobra R block had a unique Cobra R part number, and they're not

available as replacement parts from Ford! Joe got confirmation from Ford (on

dead trees, beloved of bureaucrats) that it was okay to use a truck block.

Paper is your friend...

The next problem was an intake manifold. There are lots of EO'd manifolds

out there, but the EOs are only valid for pickup trucks. (as of when we began

this project, back in '98) Apparently the CARB almost never checks to see

that an EO-marked part is actually valid for that particular vehicle, but we

were assuming a worst-case scenario. There were two legal 351W intakes - the

original Cobra R part, with either the original cast upper or the GT-40

tubular upper, and one from Saleen. There didn't look like there was a whole

lot of difference between them, so we went with the Ford bits for stealth

reasons. We knew that it was possible to flow more air through the cast upper

than the tubing upper if it was ported enough, so Joe sent the intake off to

Extrude Hone, who lightened his wallet substantially while taking probably 1/4

inch out of the runners. The intake is still going to be the cork in the

whole setup, but it's as good as it gets... that's indisputably 100% smog

legal for his particular setup, anyway.

I wavered back and forth on cam selection. The engine would have enough

cubes to tame a Ford E303, which is - somehow - smog legal, but reports from

people who have used them said passing smog could be iffy even with a 5.0. We

were building a much larger engine, but we still had to meet the same limits.

I decided to cheat and ordered a somewhat smaller Crane hydraulic roller that

was not EO'd. I already had an EO sticker from an E303... but when the new

cam came in, it came with the sticker! Crane had run it through the CARB

certification procedure between the time the catalog was printed and when I

ordered the cam.

The particular Edelbrock heads we used were the best available at the time.

We waited several months since various places kept talking about smogging a

better head, but we finally had to go with what was actually for sale.

There are some more pictures, but they're still on undeveloped 35mm waiting

for round tuits...

Internals:

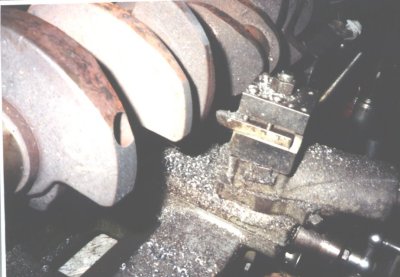

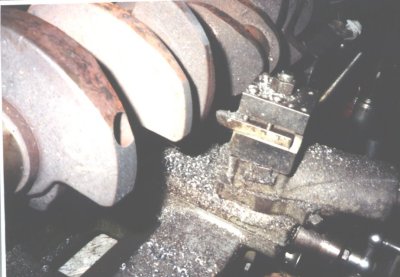

The crank is a 400 Ford casting, as usual. It has already been stroked to

4.06" and cut down to 240/Six rod journal size. The counterweights have been

profiled for piston clearance at TDC, which is why they have such an

exaggerated football shape. Now I'm cutting the OD down so it'll spin inside

the Windsor block.

I scrounged a matched set of 240/Six rods. They have to be narrowed on both

sides to fit the 400 crank. The rod bolt notches got polished, the bolts

replaced with ARP parts, the rods got resized, etc. The length is 6.2".

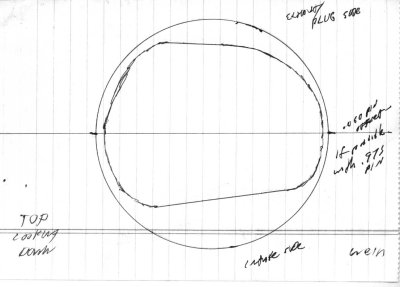

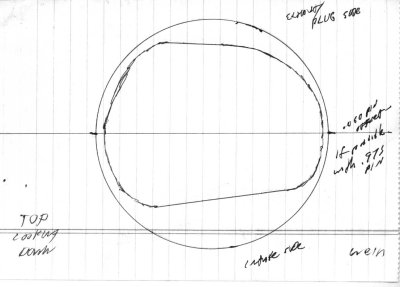

I made a tracing of the Edelbrock combustion chambers to FAX to Wiseco for the

pistons. You have to make it very plain whether you're showing the view from

the piston side or the head side!

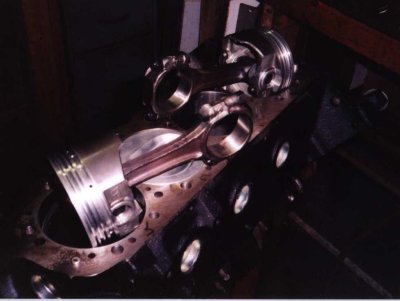

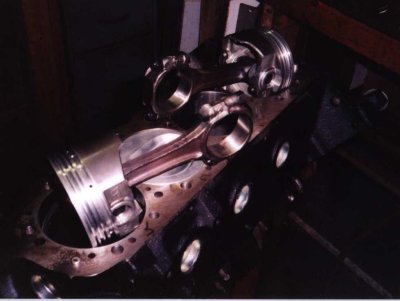

$750 worth of Wiseco custom forgings. They CNC-machined a mirror dish in the

tops according to a pattern they had that was pretty close to the one I sent.

They have .975" pins to match the 240 rods. Even with the dish tops the CR is

10:1. They've just been untaped after ceramic coating; the next step is to

moly coat the skirts.

The tag that came with the pistons gives their dimensions.

Even though this was only a 4.06" stroke the camshaft and connecting rods

collided. Only three, for some reason. Usually it's four. On the top of the

rod, hopefully made clearer by the white posterboard, is a lump of clay

showing the rod clearance to the cam. The rods that hit got their shoulders

beveled slightly. It didn't take much, just removal of the sharp corners.

Heads:

At the time we built the engine, the best of the California-smog-legal heads

were the Edelbrock Performers. This particular set came in with the seats

sunk far into the combustion chambers and stacks of shims under the springs,

which would have been an automatic return, except I had to work on them

anyway. I smoothed the seats in while polishing the combustion chambers,

blanded the bowl areas, and polished the exhaust ports and chambers.

Here we are, complete. I never could get a bright finish on the chambers, but

they're smooth. The circular lines are plain old scribe marks to indicate the

limits of where I should grind on the chambers; they just *look* like O-ring

grooves. The valves have been extensively modified and ceramic coated. The

stock Edelbrock springs and retainers were replaced with Crane bits which were

needed for the high-lift-rate cam. This took considerable juggling with

offset keepers and shims to get the installed heights correct; the Crane kit

comes for Ford 5.0 heads which have different valve stem heights.

Assembly:

Just parts laying around; I probably put them there to get some room while

clearing some free space on the workbench.

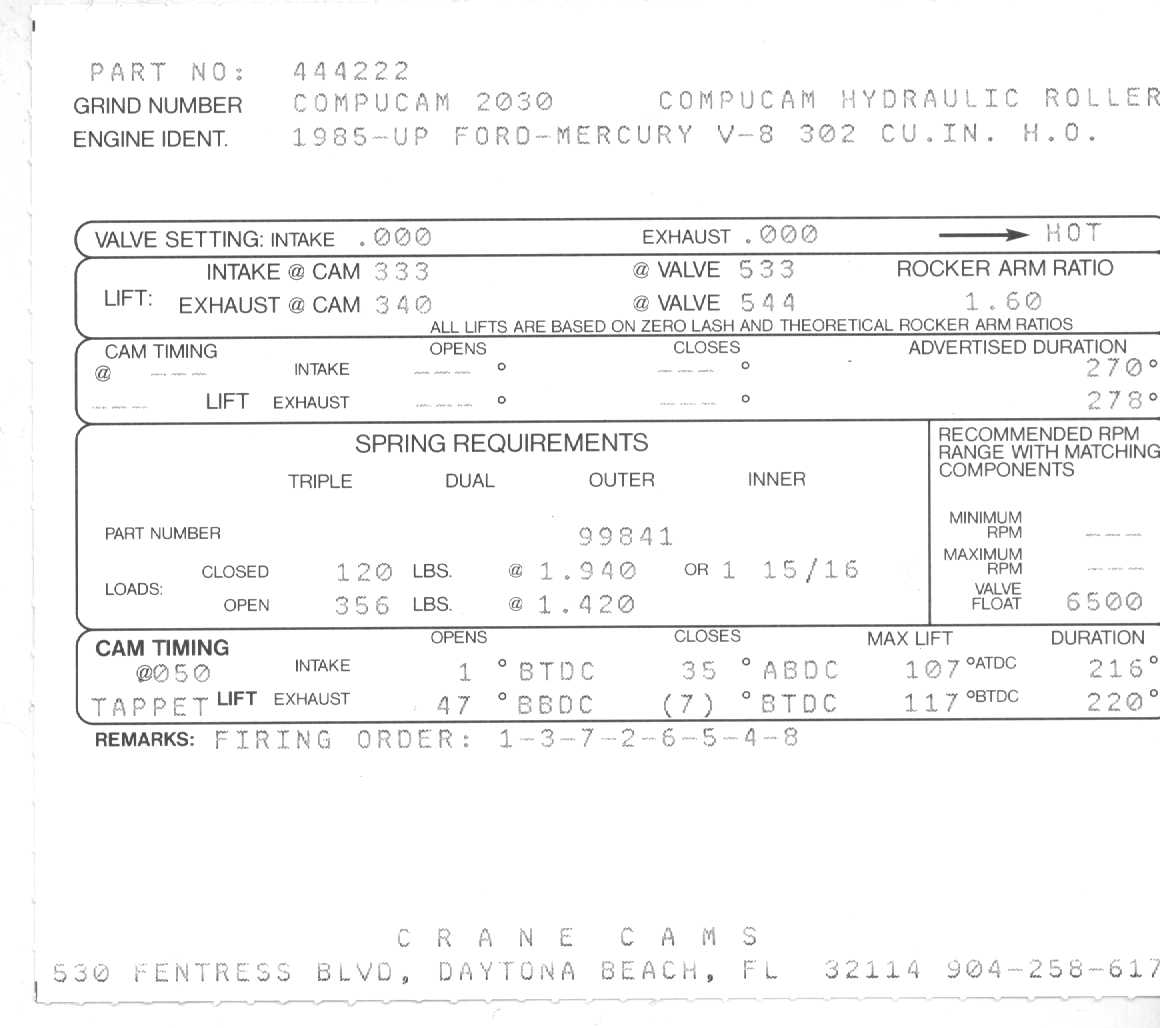

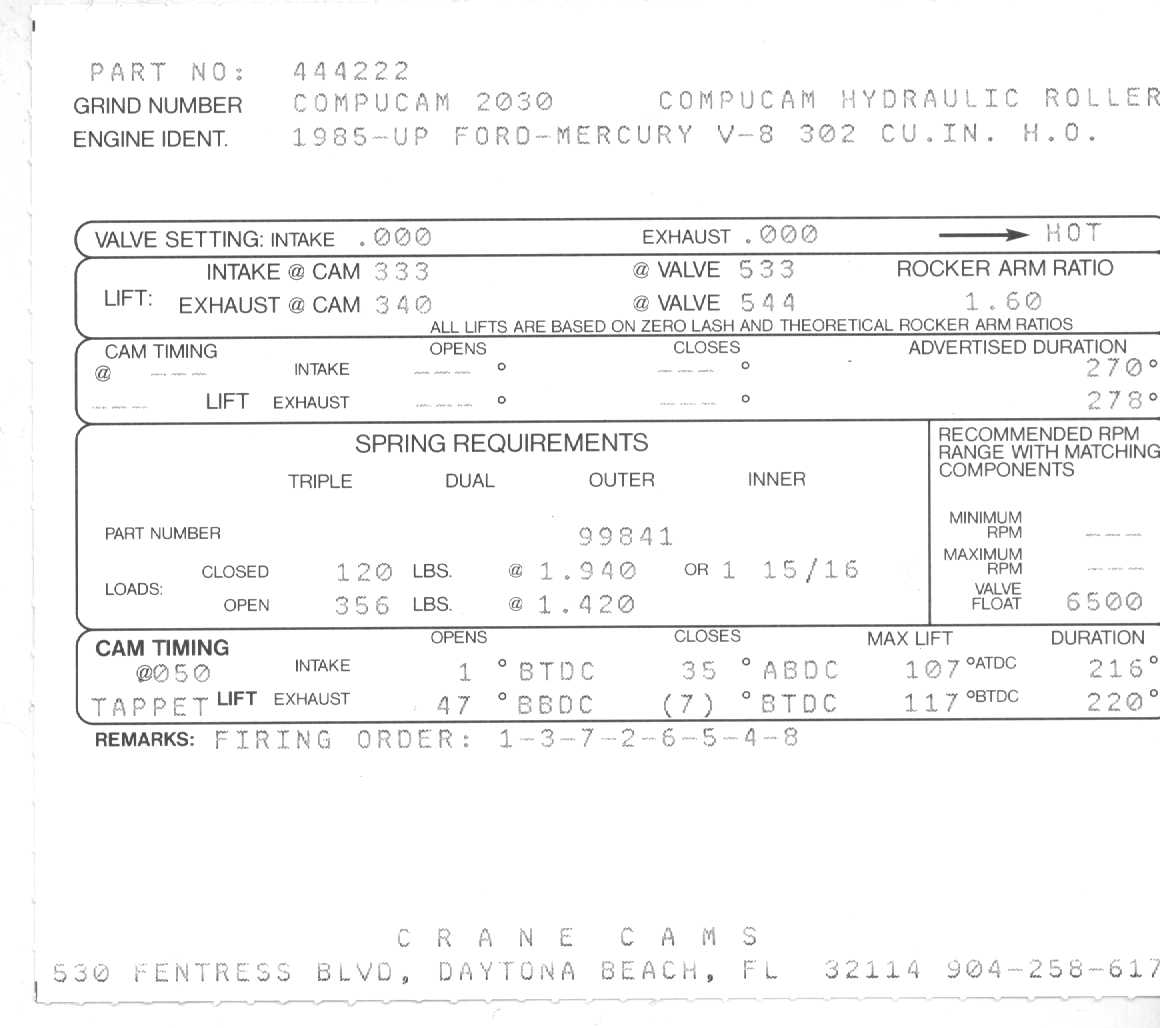

The card from the Crane cam gives its specifications. It's well within the

limit of being practical in a smog engine.

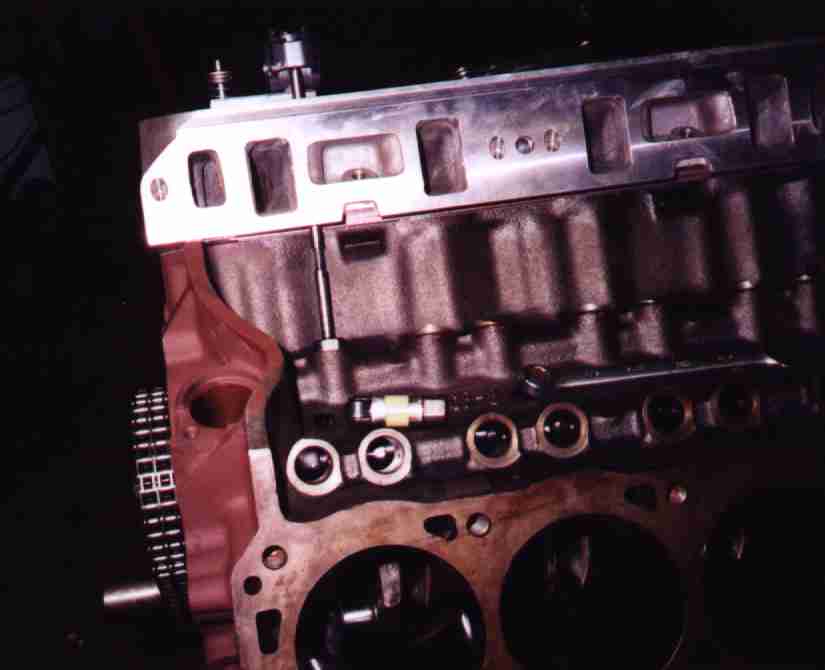

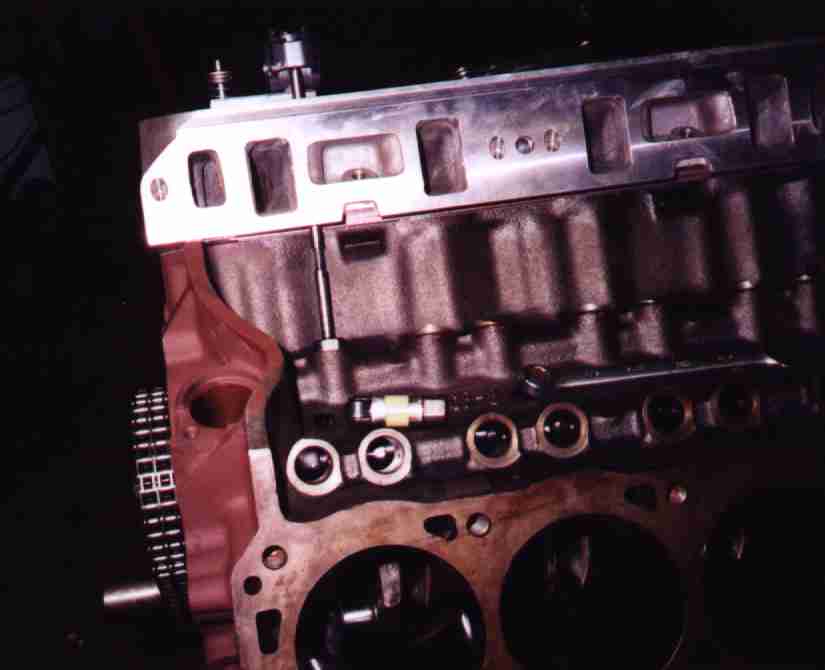

This is one of many trial fits; this time to get the pushrod length. I have

an adjustable pushrod and some -.030" solid roller lifters for doing this.

The 50oz 5.0 balancer needed a seal saver. This particular one even came with

a little tube of sealer. The seal savers are very thin and stretch quite a

bit on installation; sometimes getting one on without collapsing it can be a

trick.

Brand new Ford 50oz 5.0 flywheel and matching ARP bolts.

Final assembly now; here I'm checking flywheel runout. T.I.R. (total

indicated runout) was under .003"; dead nuts. You can see the "spectacle"

shape of the piston dishes pretty good in this shot.

Just some assorted hardware - new timing cover dowels, new oil filter adapter

(the brand new Ford block didn't come with that, though it came with cam

bearings!), balancer bolt, and the weird triangular-looking thing is actually

the timing pointer. I had to do a slight hammer adjustment to make it line up

with the marks on the damper when I degreed the TDC mark in.

The cast rockers are just fine for the sub-6500 RPM range the engine will run

at. They're the pedestal mount type. Those are custom Howards Cams

pushrods. Cams vary in base circle, rockers vary in geometry, valve stem

length differences... it's amazing so many late model Ford guys don't run into

more trouble than they do. The customs give the roller lifters .030" of

preload as Ford recommends.

The assembled long block at last! The valve lift looks low, but that's an

illusion. The lifters are empty, so there's a lot of lost motion until you

prime the engine and get some oil to them. Ford recommends *not* pumping the

lifters full of oil since it makes it hard to check the preload on assembly.

Oil Pan:

Joe's car has an oil sensor in the pan and the new Canton pan didn't come with

a bung for it. I MIG welded one in and smeared some epoxy around just in

case. The Canton came with a gold finish, but it was sort of mangy and all

the welding and hammering didn't help it any, so I painted it black to match

the rest of the engine.

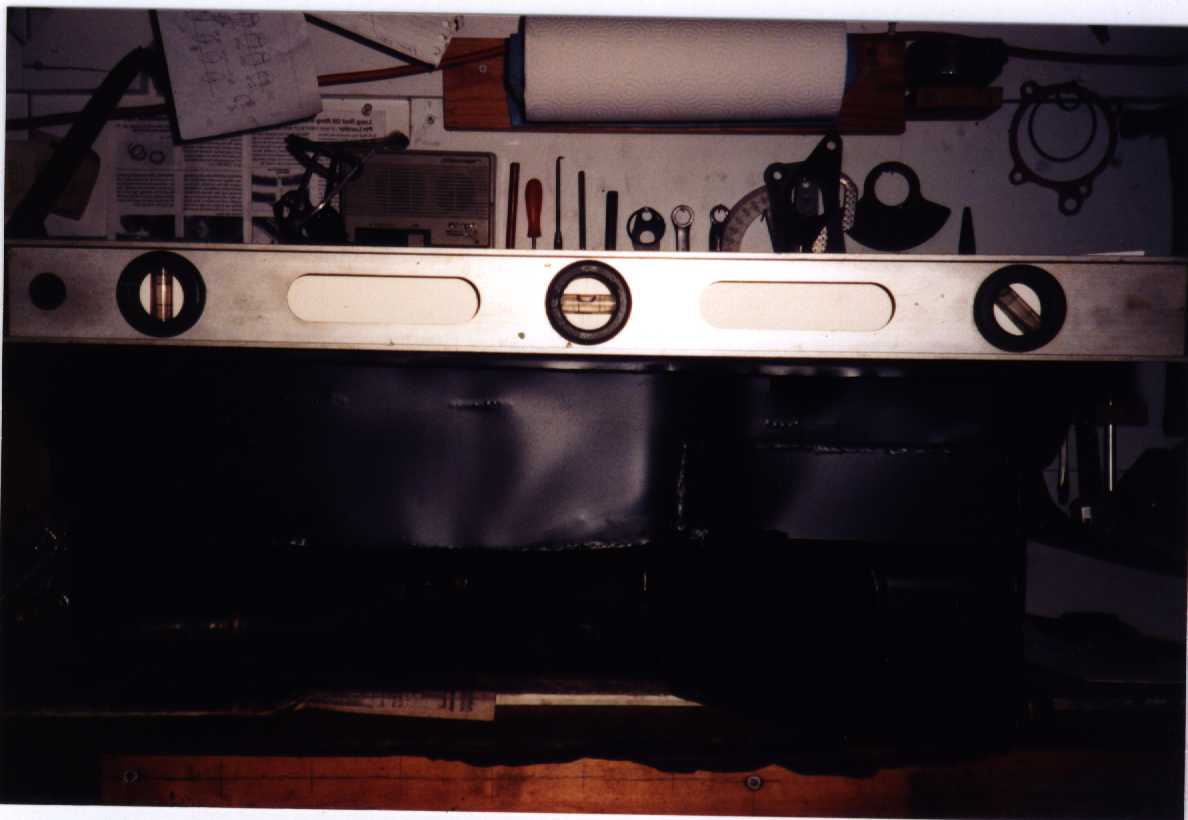

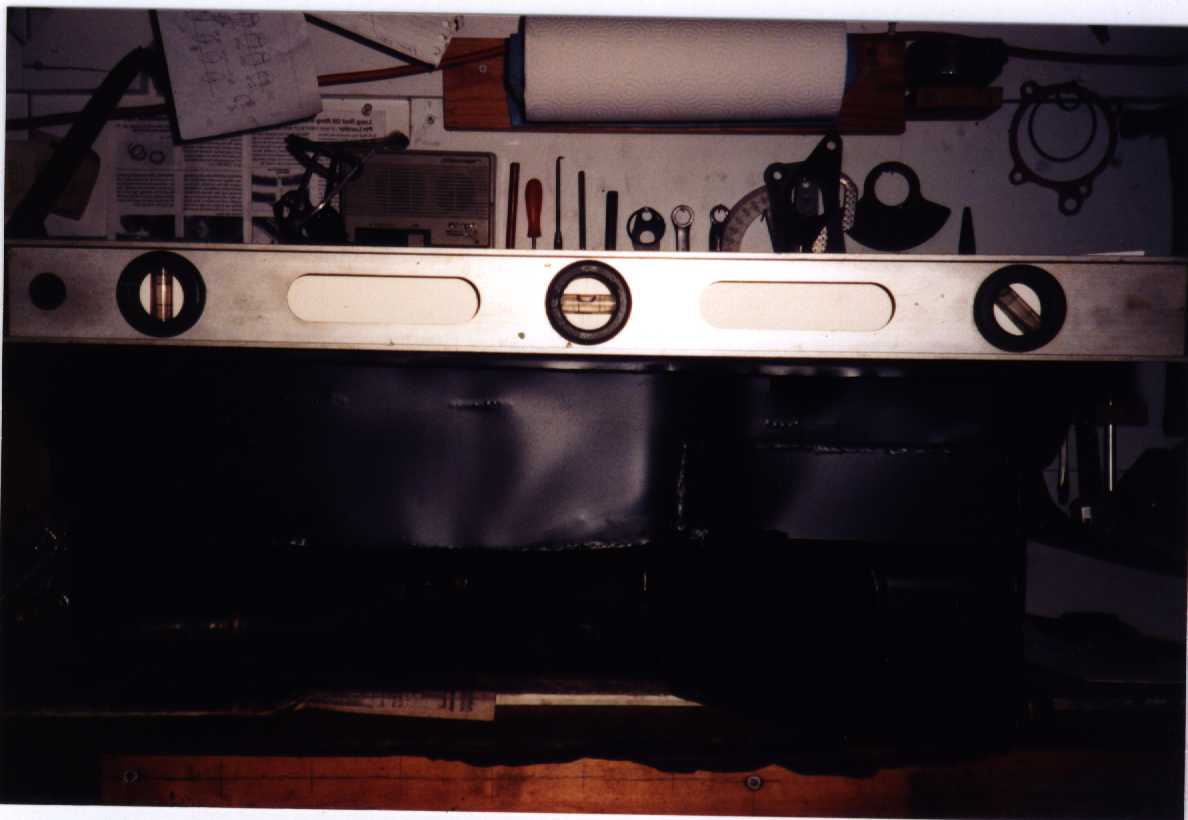

I tried to get a good shot of how wavy the Canton pan rail is. It's almost a

quarter inch out in various places. I didn't think to look before I started

modifying the pan; Canton's quality control used to be good. I've seen

a steady deterioration of their products over the last few years.

The bolts appeared to be able to pull it down snug, so I left it alone and

used it. At least, I tried. I was unhappy to find out the rail was not only

flat, but wouldn't clear the oil pump where it bolted up to the block!

The pan rail was wide enough to hit the oil pump where it bolted up to the

block. I looked at grinding on the pump for clearance, but it didn't look

like I could grind enough, and the Ford pumps are sort of weak looking down

there anyway.

The pan rails were already very wavy - Canton's quality control has gone to

crap - and I figured the pan would warp like an 8-track on a dashboard if I

just started torching on it. So I made a fixture of 1/4" steel flat to help

hold it straight.

After the torch and hammer.

The resulting clearance dent worked fine, and the rail was unharmed. I could

have just beat and torched repeatedly, but I figured I'd get the opportunity

to use the fixture more than just this once...

Another view of the clearance dent.

The Canton pan was full of MIG spatter from when it was made, and I kept

finding bits of metal in the myriad nooks and crannies where pieces of metal

overlapped. I used soap and water, the pressure washer, and lacquer thinner

sloshed inside to remove most of it, then modified a spare air gun with a 1/4

NPT compression fitting and some 1/4" copper tubing. That let me get into all

the places that would ordinarily have been inaccessible.

Canton provided a new Ford oil pump pickup tube with the pan. I liked it

better than Canton's homemade ones.

Intake:

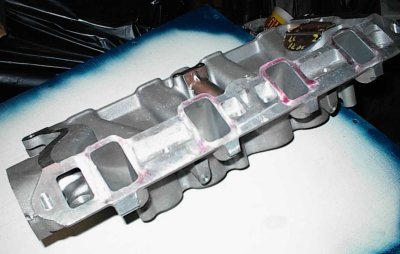

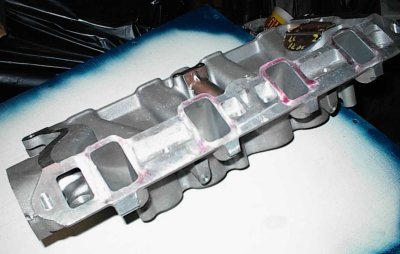

This is the fancy Extrude-Honed intake manifold...

Manifold base. The ports are almost double the area of the ones on a stock

truck lower!

The Extrude Hone process isn't all that precise. Note how the openings aren't

quite rectangular and have wavy areas. It wasn't worth going after it with a

grinder. The process works rather well, considering the putty goes where it

wants to.

Better shot of the port irregularity.

Top side of intake. EH bolts steel "gasket" plates to this and the bottom

side to keep the glop from wearing big funnel shapes at the entrances and

exits.

The runners on the Cobra intake are about as straight as you'll find for a

conventionally arranged Ford injection setup. See the kink in the runner to

the lower left? That's #5 cylinder, the one that causes a lot of problem with

Ford EFI intakes. The ports in the head sweep to the side; forward on that

side, backward on the passenger side. That's the wrong direction to line up

with the manifold runner, which is limited by the space needed for the

distributor. The Cobra intake puts the kink early and tries to straighten the

path out somewhat. Every little bit helps.

The upper isn't nearly as troublesome. The staggered rows, besides helping

line the ports up on the base, also allow larger diameter runners than if they

all had to be jammed side by side, like with the standard 5.8L truck intake.

The dividers at the plenum end got pretty thin, though the edges are nicely

rounded. Much better looking than the stock layout.

Another shot at a slightly different angle. I'd like to have one of those

fancy borescope attachments for the camera!

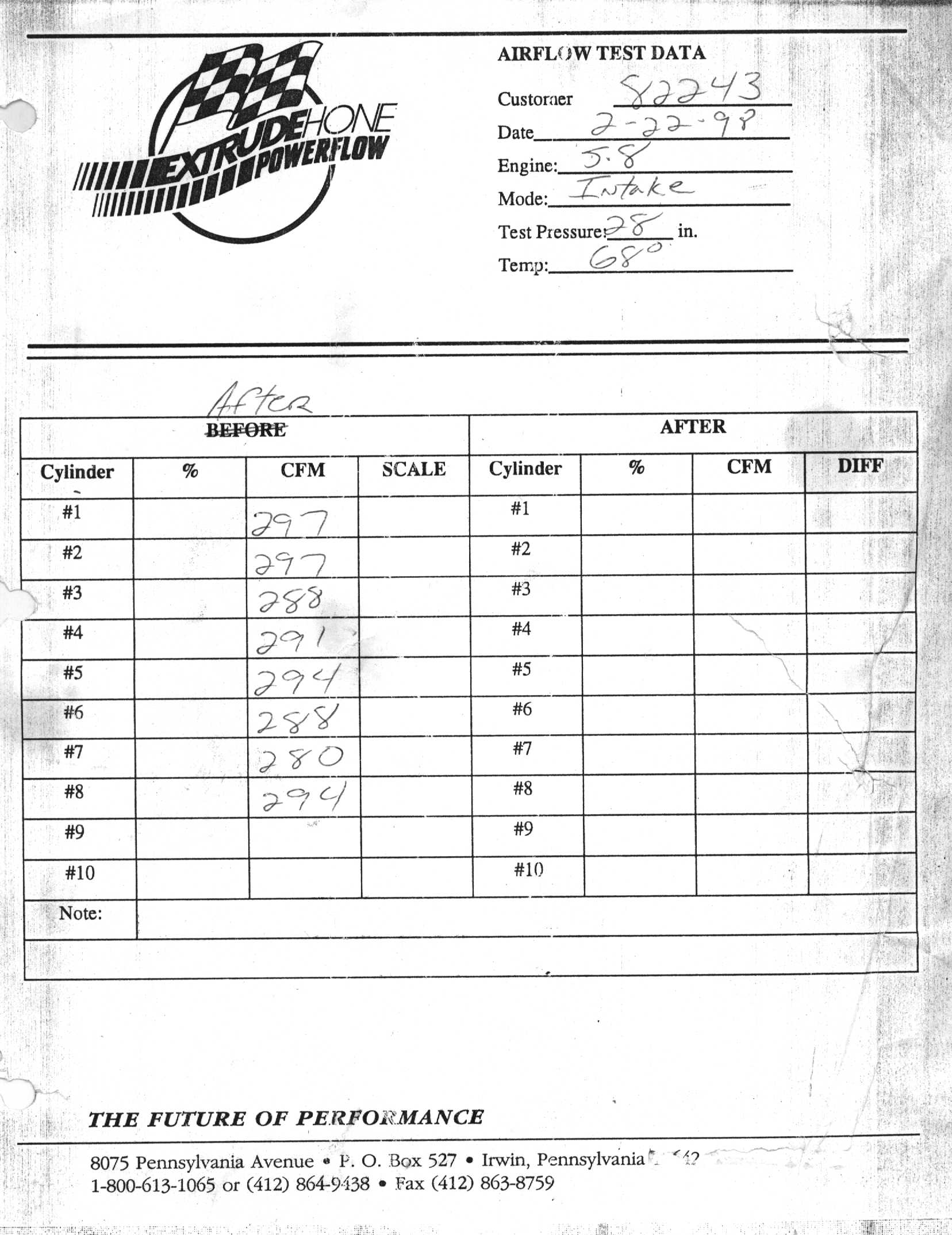

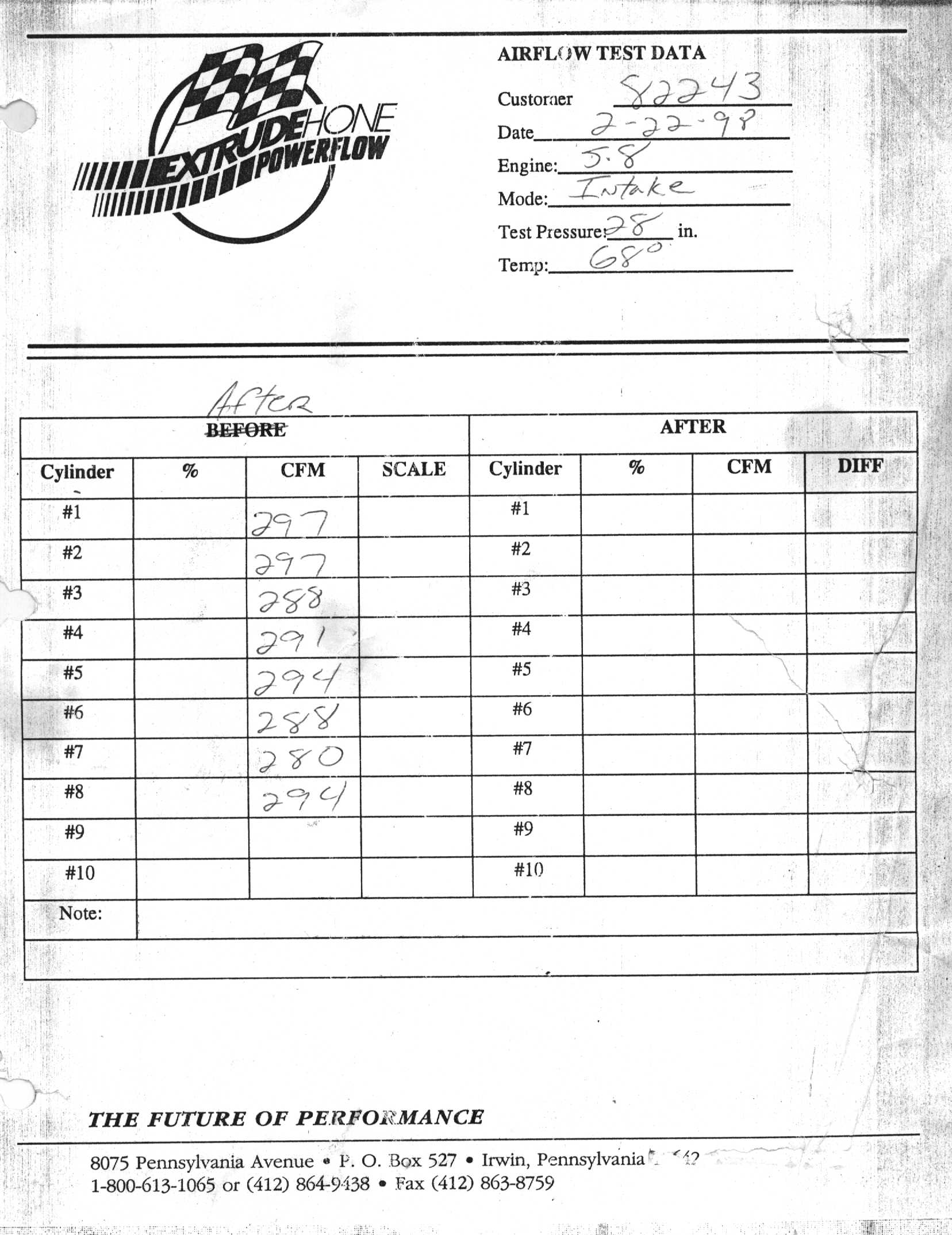

Extrude Hone provided a flow bench test sheet with the intake. ~290 CFM is

pretty good, but the long, long runners will make the intake resonant at a

lower RPM than I would have liked, but you can't have everything when you're

juggling E.O.'d smog bits around.

Fire-Up:

This is another one that had to be run before shipment. I had to build some

Ford brackets for the run stand, find a bellhousing to mount the starter to,

then a 5.0 starter, etc.

Here I'm assembling bits to fire it up before shipment. I didn't have any

reverse rotation water pump bits to match the timing cover, so I made up a

garden hose adapter. Ten feet of 5/8" clear plastic tubing comes off the

intake manifold, which is an old cast iron 2bbl part. I scrounged some

manifolds, adapted them to the 2" pipes on my run stand mufflers, found a 460

DuraSpark distributor and installed a Motorsport steel gear on it to match the

roller cam, stole the distributor cap, wires, starter, and valve covers off

TRX, etc... it takes more stuff than you'd think to fire one up.

After the engine was primed, the oil pressure gauge would hit 70 PSI before

the drill made one full revolution!

For some bizarre reason I didn't take a picture of the engine all dressed up

to run. Here it's mostly stripped back down. The thermostat housing blockoff

plate was originally made for another project that didn't go anywhere; I

reused it from the parts box.

The white doohickies on the corners are Teflon sealer. That's a real 351W

intake, with 16 attachment bolt holes vs. the 12 used for the 302 or 351K,

which is what Ford called the Windsors after 1976, before they started calling

them Windsors again. [sigh] Anyway, the four extra bolts will leak water if

you use a 16-bolt intake with 12-bolt heads. I tapped the holes and screwed

in some short 1/2" bolts as plugs. Next time I need an intake to run an

engine like this I'll have it handy, but this sort of thing wound up taking a

lot of time.

Looks just fine inside... the oil was nice and clean when it drained out. Not

that I expected anything else, but paranoia is the engine builder's friend.

Shipping:

I've started taking lots of photos while crating engines now. Forklift blades

are a problem. An engine shipped to London had a fork run through the side of

the crate and through the oil pan; another sent to San Francisco was knocked

clean out the back side of the crate. Nothing will stop a forklift blade at a

running pace, but the freight companies always try to claim the engine was

improperly crated. Ford and Chevy just band an engine to a pallet and staple

some laths over it, not a proper crate at all. I do better than that...

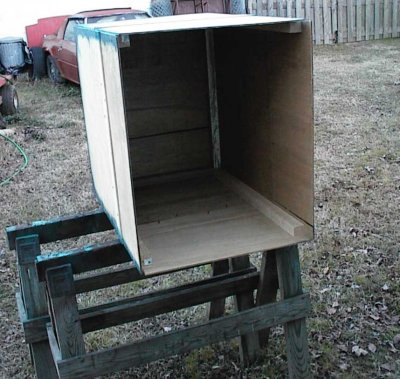

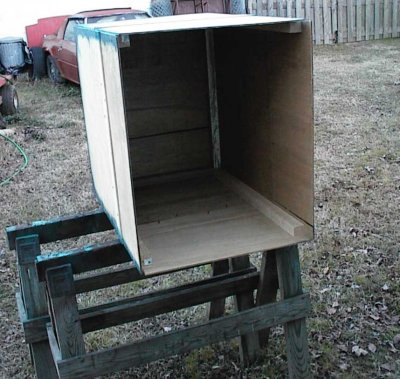

Crating one for shipment can be a hassle. Here's the beginnings of the base

platform; a 2x4 frame, 3/4" floor, and some odd-size pieces for cross braces.

The box part is 1/4" plywood. It'll slide right over the top and get held

down with screws around the edges. The plywood was supposed to be some

cabinet doors, but it was about the right size, and I needed some plywood, and

besides, if I hadn't put the doors on after two years, I probably wasn't going

to... the the strips are where I spliced narrower pieces together. The

corners are 2x2s.

Everything taped off or plugged, lots of supports and blocks to keep it from

sliding around. The metal straps are just to keep it in contact with the

base; it can't slide around anywhere.

Lots of pieces of scrap lumber. The kickouts in the pan made it awkward to

use the usual pan rail method of supporting the engine. Most of the weight is

on the rails, with the sump in light contact with shims underneath. I didn't

want the whole weight of the engine sitting on the welds.

Yet another shot. Long wood screws keep everything together.

The upper intake would have made the engine too tall to lift high enough to

clear the tailgate, so it'll be added later. Temperature was about 18F and

windy right then... that's the chassis for a V8 Lotus 7 knockoff leaning

against the back of the house.

The water pump, fuel rails, an extra copy of the shipping instructions, and

other paraphernalia are fastened to the engine or crate with zip ties and/or

wood screws. Tyrannosaurus RX visible to the left, still waiting for the new

high-zoot driveline to replace the punked 302 and C4.

Several layers of plastic for waterproofing, in case the trucking company

leaves it outside in the rain. It's happened to me before. The upper intake

is just held on with a couple of bolts; it had to ride *somewhere*...

The plywood box slides down over the sides of the base and is held down with

screws. It made it to Griggs Racing in California without incident.

Specifications:

MAXIMUM OVERDRIVE RACING ENGINES

410W Ford stroker

completed 11/18/2001 for Joe Weinstein, Moraga, California

*****

351W Ford stroked to 4.06", stock 4.00" bore (408 CID)

Crane #2030 hydraulic roller cam, 216/222deg @ .050", .533/.544" lift

Edelbrock Performer aluminum heads

*****

warranty: If it breaks, you get to keep all the pieces you can find.

�

OIL FILTER-----------------------------------------------------------------

* oil filter application: 1978 Nissan 510, 2.0L 4 cyl (L20B)

Purolator Filter number L30119

Fram PH2850

Motorcraft FL-181

Wix 51452

These are full size, have no bypass spring, but do have the rubber

flapper for anti-drainback for faster oil pressure buildup on cold start.

This is technically a metric filter, but they will screw on just fine.

You might want to keep everything clean so you can take one back if they

have made a production change that keeps them from working.

*Check* for the rubber flapper and no spring, just in case the filter

maker has made a change. You can do without the flapper, but you don't

want the spring.

If you need a half height filter use the Purolator L22167 or equivalent.

�

TORQUE SPECIFICATIONS -----------------------------------------------------

--------torque---------------spec-----------thread---lube------------------

rod bolts

stretch to .0065 (ARP spec .0062-.0067) 3/8-24 ARP moly lube

main cap bolts

torqued to 95 ft-lb (Ford spec 90-100) 1/2-20 30wt ND oil

note: 1) use moly grease under bolt head

2) step 1: 50 ft-lb

step 2: 70 ft-lb (reverse pattern)

head bolts

torqued to 75 ft-lb (ARP spec 75) 1/2-13 ARP moly lube

note: 1) use hardened washers, ARP moly grease both sides of washer

2) block is blind tapped, no sealer needed

3) step 1: 50 ft-lb

step 2: 75 ft-lb (reverse pattern)

4) heads must be retorqued after two days, or after engine is first

run

damper (harmonic balancer) bolt

(Ford spec 70-90) 5/8-18 30wt ND oil

note: use automatic transmission fluid as lubricant when pressing damper on

intake manifold bolts

(Ford spec 23-25) 5/16-18 sealer

exhaust manifold bolts

(Ford spec 18-24) 5/16-18 antiseize

rocker bolts (torque 40 ft-lb) 5/16-18 30W ND oil

timing chain sprocket bolt

torqued to 40 ft-lb (Ford spec 40-45) 3/8-16 Loctite 272 blue

cam retainer plate

torqued to 10 ft-lb (Ford spec 9-12) 1/4-20 30wt ND oil

oil pan bolts

(Ford spec 7-9) 1/4-20 oil

(Ford spec 9-11) 5/16-18 oil

oil drain plug

(Ford spec 15-25) 1/2-20 oil

water pump bolts

(torque 12-18) 5/16-18 antiseize

timing cover bolts

(torque 12-18) 5/16-18 oil

1/4 NPT threaded oilway plugs Loctite Pipe Sealer With Teflon

or silicone sealer, Teflon pipe sealer

oil pump pickup

(Ford spec 9-11) 5/16-18 Loctite 242

oil pump cover plate

(Ford spec 9-11) 1/4-20 Loctite 242

oil pump body

(torque 30-35) 3/8-16 Loctite 242

spark plugs

14mm antiseize

bottom pulley to damper

(Ford spec 35-50) oil

valve cover

(Ford spec 3-5) 1/4-20 oil

fan to water pump

(Ford spec 12-18) 5/16-24 antiseize

flywheel bolts

(ARP spec 85) 7/16-20 30wt oil

�

COMPONENTS ---------------------------------------------------------------

Heads:

Edelbrock Performer aluminum heads

Edelbrock recommends Champion RC12YC for a baseline plug

1.94/1.60 valves

disassemble

polish exhaust ports

scribe chambers to cylinder bores

lay chamber walls back to block scribe lines

feather in valve seats in chamber

smooth valve seats in ports

polish combustion chambers and exhaust ports

install Crane 44308 springs and retainers, set spring heights

sandblast valve heads

coat valve heads with CBC2 ceramic thermal barrier, bake, polish

back and face cut valve for low lift air flow

regrind valve faces

regrind seats

clean

assemble

vacuum check

Valvetrain:

custom Howards 5/16" pushrods

7.53" installed on exhaust

7.55" installed on intake

lash caps on exhaust side

1.94" installed height on Crane #44208 valve springs, +.050 keepers

new Ford roller lifters

Competition Cams lifter spider

Competition cams aluminum pedestal roller rockers

Crane hydraulic roller cam #444222

216/220 deg duration at .050"; 270/278 advertised

.533/.544 lift with 1.6 rockers

valve float limit 6500 RPM with 356# springs

firing order: 1-3-7-2-6-5-4-8

Ford Motorsport M-6268-A302 roller timing set

Block:

new F4TE roller 351W block

clearance block for stroker crank

chase threaded holes

touch hone bores #600 finish with torque plates

install oil and water plugs

clean

paint semi-gloss black

Crank:

Ford 400

clean core

Magnaflux

offset grind to 4.060" stroke

turn mains .020" undersize

lay back snout ring for Windsor timing sprocket

shorten nose to Windsor length

turn down OD to fit Windsor block

shape OD to fit 6.2" rods

trim oil slinger flange down

cut second keyway for timing sprocket

install keys

bevel front edge to clear oil pump

polish journals

clean

balance to 50 oz 5.0 flywheel and damper

Rods:

Ford 300 Six, 6.2" long

hot tank

Magnaflux

glass bead

narrow sides on mill fixture

deburr and dress sides

knock out old bolts

cut shanks and caps

install new ARP bolts

resize big ends

chamfer big ends

balance

adjust side clearance on final assembly

bevel corners of #5, 6, 7 for cam clearance on final assembly

standard width rod bearings, not narrowed, std/.001, .001s on bottom

Pistons:

Wiseco custom forgings

4.00" diameter

custom CNC dished tops to mirror Edelbrock chambers

18cc dish volume

pin height: 1.26"

pin diameter: .975 (300 Six)

wristpin offset: .060"

ring widths: 1/16 1/16 .217 (3/16 + spacer)

mask, sandblast

demask, clean

coat TLML moly antifriction on skirts

coat CBC3 thermal barrier on tops

demask

bake

buff

wash

Speed-Pro file fit moly rings, 1/16 1/16 3/16

Assembly:

check rod to block clearances (.100 minimum)

check rod to cam clearances (.060 minimum)

check piston to crank clearances (.040 minimum)

degree cam

check rod side clearances

#1 .008

#2 .011

#3 .010

#4 .008

check crank end play

check valve/piston clearance

check pushrod length

hang pistons on rods (pressed pins)

file fit ring gaps

verify TDC on harmonic balancer

install new Ford roller pilot bearing

Induction:

Ford 1993 Mustang "Cobra R" 351W intake

Ford cast upper

Extrude Honed

flow figures (CFM@28"):

cylinder # CFM

1 297

2 297

3 288

4 291

5 294

6 288

7 280

8 294

fuel rails: Ground Pounder billet aluminum

Oiling:

Melling oil pump

new Melling 351W drive rod

Canton 351W-Fox rear sump pan

weld in bung for oil sensor

heat and bend rail for oil pump clearance (bad pan)

remove factory MIG spatters

straighten uneven rails as much as possible

tweak oil pickup to clear stroker crank

Miscellaneous:

turning torque, short block with cam, 35#

new Ford 5.0 flywheel, 50oz

flywheel .003 TIR

ARP flywheel bolts

Edelbrock aluminum 5.0 reverse rotation water pump

Ford 5.0 reverse rotation timing cover

ARP head bolts

Dana/Victor gaskets

Assembly:

find pushrod length

check valve/piston clearance

check rod/cam/block clearance

find TDC and adjust timing pointer

degree camshaft

file fit rings

check piston clearances

adjust rod side clearances

check lifter preload; adjust with lash caps

check flywheel runout

check oil pickup to pan clearance

trial assemble

final assemble

pre-oil with distributor tool

install carburetor intake, carb, distributor

run-in on run stand

remove carb bits, install EFI bits, crate

�

===========================================================================

assembly lubricants:

rod bearings: GM EOS

rings: Unilube two stroke oil

cylinder walls: Mobil 1 5w30

piston skirts: Mobil 1 5w30

wrist pins: GM EOS

head bolts - threads: ARP moly lube

main bolts - threads: 30wt ND

head, main bolts - under head: ARP moly grease

rod bolts: ARP moly lube

cam bolts: Loctite 272 blue

cam retainer plate bolts: Loctite 272 blue

cam lobes: 30wt oil

cam journals: 30wt oil

cam distributor drive gear: moly grease

cam retainer plate/sprocket: moly grease

crankshaft rear oil seal: GM EOS

�

===========================================================================

assembly notes:

Wrapper:

Leave the engine in its plastic wrap until you're ready to install it

Sealers:

sealers and thread goops usually work well when applied according to the

directions. The major part of the directions usually calls for the mating

surfaces or threads to be *clean*. Use acetone liberally to clean all metal

parts to be sealed.

don't get carried away with sealers. "Less is more". Excess sealer usually

winds up blocking the oil pump pickup. That is not good.

not all sealers are oil proof. Read the application charts before

purchasing. Use only O2-sensor-safe sealers

most sealers should be allowed to dry to some degree before the parts are

assembled. *Read the directions*. *Follow the directions*. Don't get

impatient. Have another beer, take a leak, or clean up some of your mess

while you wait.

Cleanliness:

keep your hands and tools clean and you have less chance of dropping crap

into your new motor and less chance of slicing a hand open when you slip

with a slimy tool. A 75 cent roll of paper towels and $1 tub of hand

cleaner will do.

Money:

Once you get everything ripped apart you will begin to hemorrhage from

the wallet as you find things that must or should be attended to while the

engine is out. Remember, everything always costs more and takes longer than

you figured.

�

INSTALLATION: ------------------------------------------------------------

Use sealer on the oil pressure sender.

Wire wheel or otherwise thoroughly clean the water temp sender. Install

with a minimal coat of antiseize. Sealer and corrosion can cause

resistance at the joint and will make the sender reading inaccurate.

Throttle linkage - oil it all while it's loose. If it's a cable, oil it

using a modeling clay funnel or motorcycle cable oiler

Make sure the battery cable isn't resting on a header or exhaust pipe.

Make sure the battery is grounded to both the chassis and the engine. It

probably has a big wire to the block or head and some little cheesy wire

from the intake manifold to the firewall. Use at least #4 (battery cable

size) direct from the negative post to the starter and to the chassis.

Your starter and headlights will appeciate it.

Your new motor will probably take *much* more oomph to turn it over than

the old one. You might want to have the starter looked at before you

put everything back together. It'll never be any easier to get to than

right now.

Use antiseize on the starter bolts.

Make sure the battery is fully charged before trying to start a new motor.

�

RUN-IN: -----------------------------------------------------------------

Make sure you don't have any loose wires or hoses in the way of the fan

before firing the engine. It is a great temptation to just start it up

with nonessentials hanging hither and yon.

Pour in 5 quarts of your favorite brand of non-synthetic oil, 10-30 or 10-40

weight, and screw on an oil filter. It probably wouldn't hurt to fill the

filter before putting it on.

With the "+"coil wire disconnected and spark plugs out, crank the engine over

until oil comes out the pushrods, or use an engine priming tool and a drill.

Attach the coil wire and valve covers, put the plugs in, attach plug wires.

Fill the radiator with straight water.

Smoke and noise will come from the motor as paint burns off, etc. Ignore

anything that doesn't sound terminal. Water temp will probably go right on

up there; it's okay as long as it doesn't go over 230 or boil over. If you

have near neighbors remember this will make a fair amount of noise.

Oil Viscosity:

Use the lowest viscosity oil required to maintain hot idle oil pressure of

at least 25 psi. This will circulate the maximum amount of oil through the

bearings. Very thick oil just goes right through the popoff valve built

into the oil pump and you can be starving the bearings while the guage

happily reads 60-80 PSI.