Author: Dave Williams; dlwilliams=aristotle=net

No way.

That's an aftermarket aluminum block, and that's a 351 Cleveland sprocket, so there's no room to get any puller jaws back there. I ground down the jaws on two pullers, but they wound up about .090" thick and simply bent when I tried to remove the sprocket.

I bought a matched pair of small crowbars, which couldn't get enough leverage to budge the thing. Then I tried making a puller out of angle iron and bolts. It simply bent into scrap when I leaned hard on the wrenches. I made another. No joy there either.

Finally, it was down to taking the angle grinder and destroying a $150

Rollmaster timing set, or, hell, why quit when I'm losing? I already had way

more hours into the project than I could justify. Might as well go for broke.

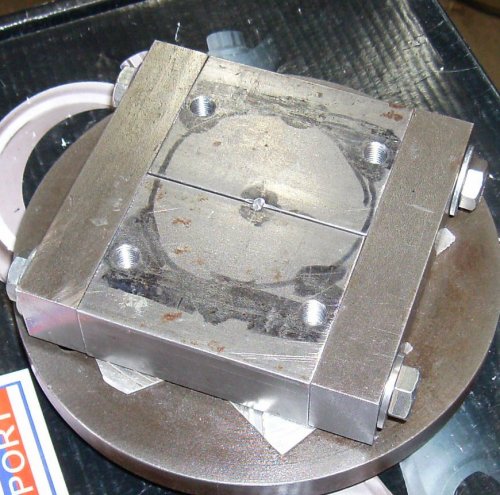

Here we are, half a day into the project. Fat chunks of 1018 cold-rolled

steel, sawed, milled to size, drilled, and tapped. It's 1-1/4" thick.

Here we are, half a day into the project. Fat chunks of 1018 cold-rolled

steel, sawed, milled to size, drilled, and tapped. It's 1-1/4" thick.

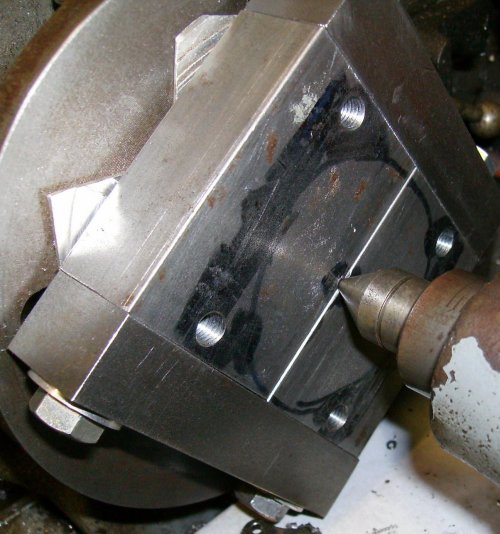

Small lathe faceplate. I normally use hardware-store washers on the bolts,

but in this case I made some heavy quarter-inch washers to hold the heavy

puller. Note the offset.

Small lathe faceplate. I normally use hardware-store washers on the bolts,

but in this case I made some heavy quarter-inch washers to hold the heavy

puller. Note the offset.

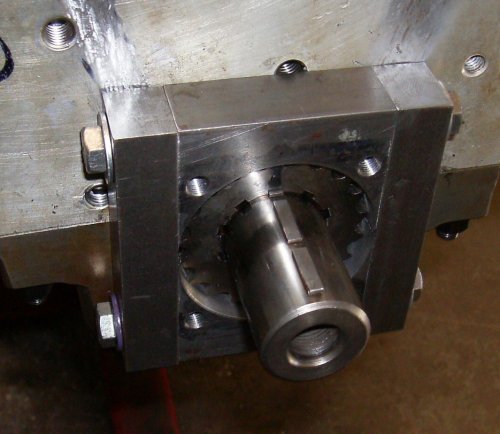

Line it up with the dead center in the tailstock. Then I used an indicator

and the brass hammer to get it closer.

Line it up with the dead center in the tailstock. Then I used an indicator

and the brass hammer to get it closer.

A bunch of drilling and boring, and now the puller is clamped to the gear.

A bunch of drilling and boring, and now the puller is clamped to the gear.

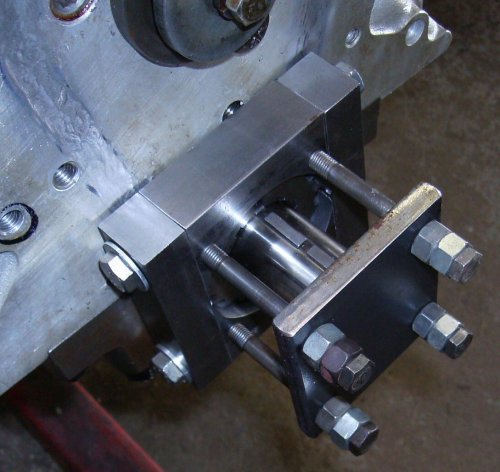

3/8" steel plate and 3/8" fine thread bolts. I put tension on the bolts,

whacked the center of the plate with the brass hammer, and the sprocket would

move a little. Lather, rinse, repeat.

3/8" steel plate and 3/8" fine thread bolts. I put tension on the bolts,

whacked the center of the plate with the brass hammer, and the sprocket would

move a little. Lather, rinse, repeat.

Voila! It's off! Hallelujah! And the SOB fought every bitter millimeter,

too.

Voila! It's off! Hallelujah! And the SOB fought every bitter millimeter,

too.

...disassemble the bits...

...disassemble the bits...

...and there's the gear! Note how thin the flange that actually pulls the

gear is.

...and there's the gear! Note how thin the flange that actually pulls the

gear is.

I had thought I might need to put some extra bolts or pins in the blocks to

keep them from swiveling when I put tension on the puller, but everything

stayed lined up fine.

I had thought I might need to put some extra bolts or pins in the blocks to

keep them from swiveling when I put tension on the puller, but everything

stayed lined up fine.

The gear looks perfectly normal under the lights in the shop; for some reason

the flash and digital camera make it look like the teeth were formed by rabid

weasels. It is a new gear, other than turning the engine over a few times by

hand to degree the cam.

If the b***h sticks again, Mr. Puller will rip its face off...