Author: Dave Williams; dlwilliams=aristotle=net

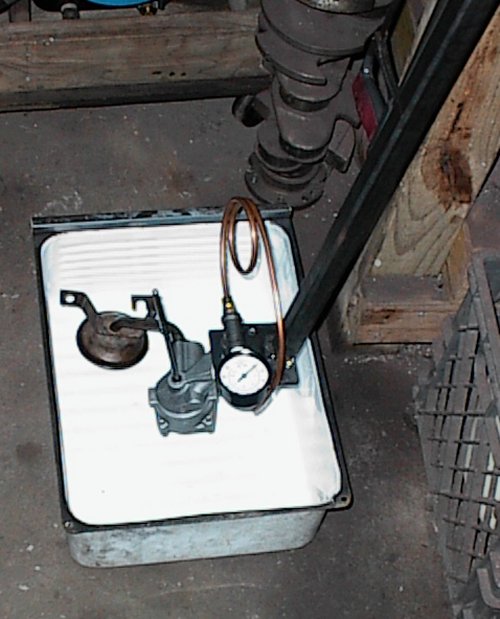

I could have cobbled something up using the block and oil pan, but I decided

to get a little fancier. I made a simple tester that I can use on many oil

pumps.

Basically, it's a piece of thickwall 1" tubing with a tapped main mounting

plate welded on at an angle. An adapter plate mounts to the main plate,

and the oil pump bolts to the adapter. This lets me mount most non-crank-

driven pumps by making a new adapter plate.

Basically, it's a piece of thickwall 1" tubing with a tapped main mounting

plate welded on at an angle. An adapter plate mounts to the main plate,

and the oil pump bolts to the adapter. This lets me mount most non-crank-

driven pumps by making a new adapter plate.

This particular one is for the Ford 60 degree Cologne V6.

The pump, its pickup, and drive rod. I eyeballed the angle on the main

plate. Not all pumps use the same mounting angle. Since I made the tester to

clamp into my big bench vise, I just angle it needed until the pickup is level

and 1/2" above the bottom of the pan. The pan is a $1 flea market item, an

enameled refrigerator bin, but any open container larger enough to hold the

pump and pickup will do.

The pump, its pickup, and drive rod. I eyeballed the angle on the main

plate. Not all pumps use the same mounting angle. Since I made the tester to

clamp into my big bench vise, I just angle it needed until the pickup is level

and 1/2" above the bottom of the pan. The pan is a $1 flea market item, an

enameled refrigerator bin, but any open container larger enough to hold the

pump and pickup will do.

1/4 NPT pipe tee has a 100 PSI pressure gauge on one side and a loop of

copper tubing on the other. There's a .100" restrictor in the tee so some oil

fill flow through the tube. The loops of tubing are so it can be bent around

to use different pans without getting a kink.

1/4 NPT pipe tee has a 100 PSI pressure gauge on one side and a loop of

copper tubing on the other. There's a .100" restrictor in the tee so some oil

fill flow through the tube. The loops of tubing are so it can be bent around

to use different pans without getting a kink.

Since this was a pump that had already had quite a bit of flak through it, I

couldn't see any reason I use two or three quarts of fresh oil, considering

what oil costs nowadays. I had some used oil on hand for my shop heater, so I

poured it into the pan. It's nasty and black, but it was already filtered for

the heater, so it would work fine.

Since this was a pump that had already had quite a bit of flak through it, I

couldn't see any reason I use two or three quarts of fresh oil, considering

what oil costs nowadays. I had some used oil on hand for my shop heater, so I

poured it into the pan. It's nasty and black, but it was already filtered for

the heater, so it would work fine.

My old Makita drill running the pump. You can't read the gauge due to the

flash, but it's sitting right on 60 PSI. Nothing wrong with the pump.

My old Makita drill running the pump. You can't read the gauge due to the

flash, but it's sitting right on 60 PSI. Nothing wrong with the pump.

The design may look at little odd, but it would be hard to beat it for flexibility!