My Workshop

slab poured 1986, $1600.

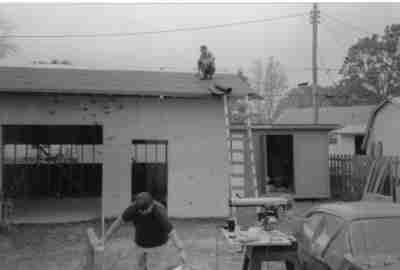

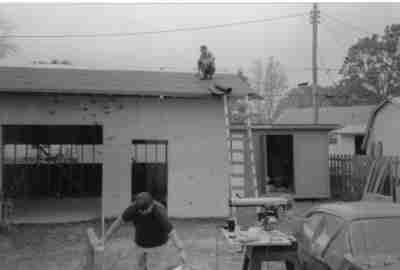

Here's the basic framing up, with some of the sheathing and a few of the

trusses. The walls are ten feet tall and the trusses are 24 feet. I designed

them myself. They're mitered together +/- 1/32", glued and screwed to 1/2"

plywood doublers. They're not your usual gang-nailed garbage. My buddy "Man

Mountain Felix" lifted the trusses in place.

My Dad put up 1000 square feet of 1/2" plywood and then tacked the tarpaper

underlayment down. I lifted the sheets up to him and he did the rest; one

eight hour day to sheath the roof. The next day I carried handfuls of

shingles up the ladder while he nailed them down in perfect alignment. Not

bad for a 65 year old! Note heavy duty 2x6 ladder.

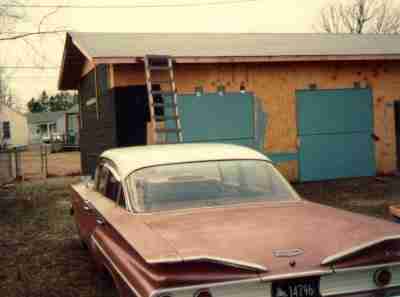

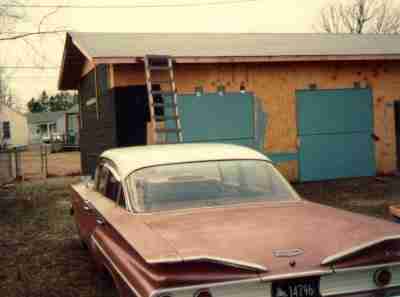

Roof is finished, sheathing and doors are on, starting with the tarpaper on

the sides. I framed the doors up from spruce 2x4s and 1/4" birch ply; they

fold up horizontally.

Dad's nailing up the cedar trim boards. He did most of the high work. The

siding is Masonite; it's not really great stuff, but it was all that was

available at the time.

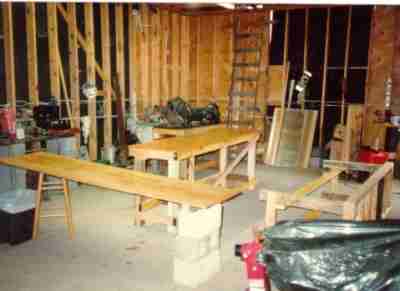

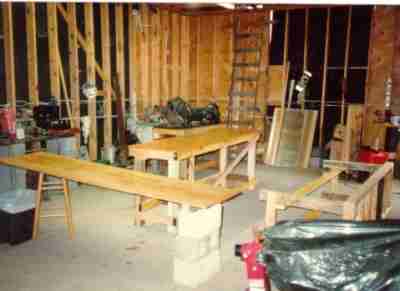

Building workbenches inside. All the sheathing isn't even nailed up yet. Due

to dramatic price increases in plywood ($6 to $16 in a couple of weeks) I

wound up using it only on the corners and filling in the gaps with blackboard.

Yes, the walls are framed with 2x6s. The difference in cost between 2x4s and

2x4s was under $100.

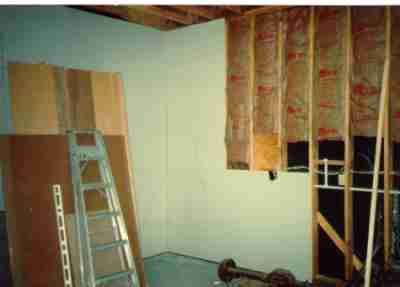

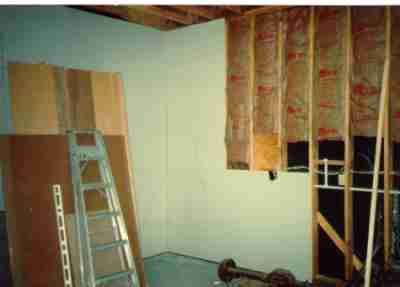

Wiring and air lines are in. I used 400 PSI rated PVC for the air lines. R19

fiberglass insulation in the walls. The sheet rock is screwed on for easy

removal and replacement; I painted it white and didn't worry about mudding it

in.

My wife had fun painting the floor. It's ordinary floor paint, not fancy

epoxy. The high traffic areas lasted about five years. Not bad, I figure.

It's "battleship gray", the lightest color I could find.

Two shots of the wiring trench. The city said the wires had to be 24" down.

It's about 30 feet from the house to the shop. It took most of a week to dig

the trench; the ground was hard as stone, and it was over 100F even at night.

I'd keep the trench flooded with water during the day, then get up before dawn

to dig the few inches of mud out before I hit hardpack again. There were

plenty of things that were more difficult to do, but this was the only one

that was downright miserable.

This photo is a source of particular pride for me. Other than the neighbor's

house, I made almost everything you see here. My Dad helped with the shed and

put the shingles on the shop.

This photo is a source of particular pride for me. Other than the neighbor's

house, I made almost everything you see here. My Dad helped with the shed and

put the shingles on the shop.

I built the shop, the shed, the ladder, the fence, the walkway, the little

porch/step in front of the shop, and AB's V8 Capri (we removed the side

windows when we painted it). I even built the sawhorses and the chassis

that's sitting on top.

Where the front of the shed is was a low spot; I hauled enough fill to build

it up almost a foot. Then I planted the grass.

For a long time, every time I went out the back door I'd stop and admire the

view.

This photo is a source of particular pride for me. Other than the neighbor's

house, I made almost everything you see here. My Dad helped with the shed and

put the shingles on the shop.

This photo is a source of particular pride for me. Other than the neighbor's

house, I made almost everything you see here. My Dad helped with the shed and

put the shingles on the shop.