Seig X2 minimill CNC conversion, part 5: motor fan

brought to you by: Dave Williams

This page: www.bacomatic.org/~dw/tool/x2/fan/fan.htm

Main page:

http://www.bacomatic.org/~dw/index.htm

Last Updated: 05 Sep 2008

Author: Dave Williams; dlwilliams=aristotle=net

The motors on the X2 mills reportedly run hot during continuous use. I

decided to put a fan on. I found a 12V fan of appropriate size in my junkbox.

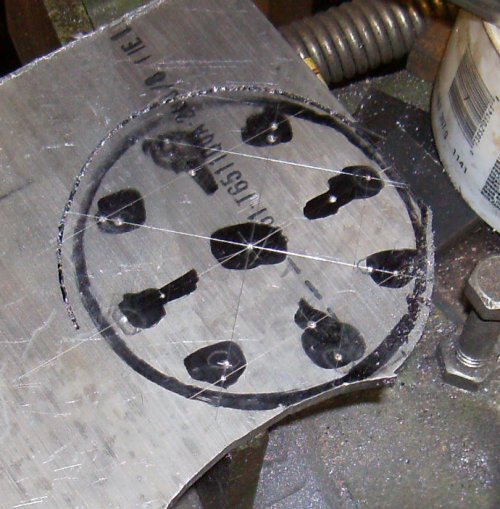

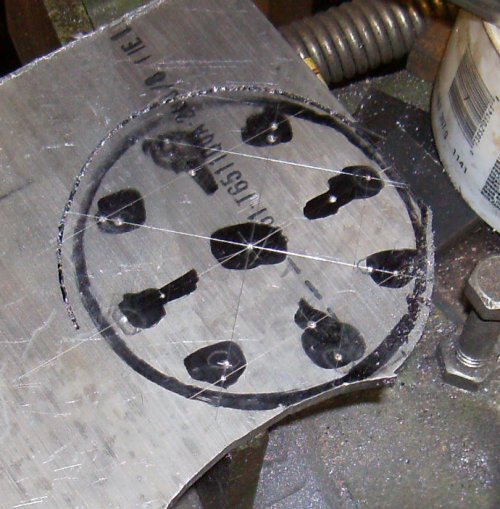

Marking out the fan and motor bolt circles on some 1/4" aluminum stock.

Partway through bandsawing it out now.

Marking out the fan and motor bolt circles on some 1/4" aluminum stock.

Partway through bandsawing it out now.

Finished bracket. The ID matches the opening of the fan, the OD matches the

motor. #6 screws go through fan into tapped holes; motor screws go through.

Finished bracket. The ID matches the opening of the fan, the OD matches the

motor. #6 screws go through fan into tapped holes; motor screws go through.

Long screw below fan is one of the original motor screws. I need some longer

ones now.

For some demented reason I always keep the little "wall wart" transformers

from old electronics. This one was for a cordless phone that died years ago.

For some demented reason I always keep the little "wall wart" transformers

from old electronics. This one was for a cordless phone that died years ago.

I wired it directly since I'll switch it through the master power strip for

the mill.

The screws holding the end bell on the motor are 4mm. I need some 50mm long

to go through the spacer, some 5/8" standoffs, and the adapter plate. No such

things were to be had locally, even by special order. I'll order some 4mm

threaded rod from McMaster later.

Marking out the fan and motor bolt circles on some 1/4" aluminum stock.

Partway through bandsawing it out now.

Marking out the fan and motor bolt circles on some 1/4" aluminum stock.

Partway through bandsawing it out now.

Finished bracket. The ID matches the opening of the fan, the OD matches the

motor. #6 screws go through fan into tapped holes; motor screws go through.

Finished bracket. The ID matches the opening of the fan, the OD matches the

motor. #6 screws go through fan into tapped holes; motor screws go through.