Seig X2 minimill CNC conversion, Part 1: X/Y ballscrews

brought to you by: Dave Williams

This page: www.bacomatic.org/~dw/tool/x2/xy/xy.htm

Main page:

http://www.bacomatic.org/~dw/index.htm

Last Updated: 18 Sep 2008

Author: Dave Williams; dlwilliams=aristotle=net

Though CNCFusion's web site talks about installing the kit on an assembled

mill, it's much easier to take it apart. In fact, you'll probably wind up

taking it all apart several times. Fortunately it's easy to disassemble.

Mine was also full of grit and cast-iron swarf, which was even on the gears

inside the head.

quandrant2005's videos on YouTube look as if all he had to do was tilt his

machine back and install the CNCFusion kit. Mine wasn't nearly as simple.

There appears to be considerable variation in the castings, and I'm happy

that CNCfusion decided to go for maximum travel with a little fiddling if

needed, but it was still a surprise when nothing seemed to fit.

This is more or less what I did for my installation:

1. remove electricals

(get stuff out of the way)

four socket head screws hold motor mount plate to main head casting

four Phillips screws hold the control box lid; four more hold the

box to the casting

four Phillips screws hold the motor driver lid; three hold the box to

the column

two Phillips head screws hold grounding wires from the driver box to

the column

set all the bits off to the side

2. remove column

(you need to get under the base, etc.; it's easier to do if it's apart, you

have to disassemble the table anyway, and it's easier to clean it this way)

it will help if the base is still bolted to the shipping platform

run the head about halfway down the column

loosen the big nut that holds the column to the base. Keep one hand

on the column so it doesn't fall over. Remove the nut and

thick washer.

slide the column away from the base, off the long stud. It is heavy

and awkward to hold on to, and covered in grease. If the

base isn't anchored to something it may want to slide around

lay the column on its back, taking care not to bend the feed levers

3. disassemble base

remove X handwheel; it is double-nutted

loosen gib screws one turn

remove the left end cap from the table

loosen the set screws that hold the X-axis bracket

loosen the set screw that holds the leadscrew nut to the saddle

slide the table off to the right

the gib will fall out. Note: my gibs had nasty burrs where the screws

rode. Though the gibs are some kind of steel, they're dead

soft, so a file or sandpaper will work fine. If you use

power tools, be cautious.

run the saddle to the back

remove the two screws from the front of the base, that hold the

Y-axis bracket

loosen the single Allen screw that holds the Y-axis nut to the saddle

slide the leadscrew out

4: clean

I used car engine degreaser and the garden hose, then blew the pieces

with compressed air. A light spray of WD-40 to delay rust.

5: clearance base casting for Y-axis leadscrew

get the Y-axis (short) leadscrew assembly out of its wrapper

remove the Lovejoy coupler

remove the spanner nut. Mine came from CNCFusion run down just snug;

I was able to get it off with my fingers

slide the motor mount off. The ball bearings are loose and will fall

out if you're not careful. Do not remove the ballnut.

slide the Y-axis leadscrew in from the bottom. The threaded end

sticks through the front of the base casting.

put the back bearing in the motor mount and attach it to the base with

the screws provided. Snug the screws down; don't over tighten.

the ballscrew is made as long as possible for maximum Y travel, but

there are variations in the coring of the base casting. With

some castings, the screw will bottom out before the motor

mount is tight. My arbitrary decision was that .005" to .050"

would be enough clearance. I wound up with .100" due to

enthusiastic grinding.

the left side of the ball nut has the recirculating tube for the

balls. On my mill, the ball nut scraped the rough side of

the clearance slot, so I had to grind some there, too.

the left side of the ball nut has the recirculating tube for the

balls. On my mill, the ball nut scraped the rough side of

the clearance slot, so I had to grind some there, too.

if you don't have enough clearance, file or grind the casting. Then

you get to clean and oil it again.

if you have access to another mill you could save a lot of grinding

don't get too crazy clearancing the back of the base casting. More

then 1/8" or so clearance and the ballscrew may be able to

run off the last thread and drop balls out. If you want to

be precise, check your screw and nut and see exactly how far

the nut may go before you can lose your balls. Someday you

might need that extra .100" or so of Y travel

don't get too crazy clearancing the back of the base casting. More

then 1/8" or so clearance and the ballscrew may be able to

run off the last thread and drop balls out. If you want to

be precise, check your screw and nut and see exactly how far

the nut may go before you can lose your balls. Someday you

might need that extra .100" or so of Y travel

6. Y-axis leadscrew nut

make sure the threads on the end of the screw are clean, and the

threads in the special spanner nut are clean.

put a drop of oil on the threads

CNCfusion's forum says you should be able to hold the ballscrew firmly

in one hand and use pliers to run the nut down snugly against

the ball bearing. This wasn't even in the same universe as

the screw and nut I got. Using a piece of old leather belt

to pad the jaws, I tried holding the screw with 10" pliers

and still couldn't get enough of a grip to run the threads

past the locking ring in the nut. I was leery of using Vise

Grips, so I picked away at the plastic locking ring with a

penknife until I could run the nut on. I figured I could use

a drop of Loctite later if needed. You might try padding the

screw with leather or wood and holding it in a bench vise to

run the nut on and off a few times to loosen it up. My nut

has plier marks all over it now. Surely there's a spanner

wrench to fit the thing, somewhere...

CNCfusion's forum says you should be able to hold the ballscrew firmly

in one hand and use pliers to run the nut down snugly against

the ball bearing. This wasn't even in the same universe as

the screw and nut I got. Using a piece of old leather belt

to pad the jaws, I tried holding the screw with 10" pliers

and still couldn't get enough of a grip to run the threads

past the locking ring in the nut. I was leery of using Vise

Grips, so I picked away at the plastic locking ring with a

penknife until I could run the nut on. I figured I could use

a drop of Loctite later if needed. You might try padding the

screw with leather or wood and holding it in a bench vise to

run the nut on and off a few times to loosen it up. My nut

has plier marks all over it now. Surely there's a spanner

wrench to fit the thing, somewhere...

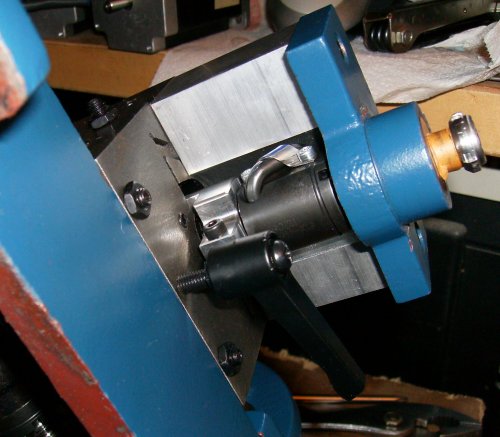

7. install Y-axis leadscrew

hold the short gib into the saddle casting and slide it onto the base.

the gib screws go to the front on top and the right on bottom.

slide the saddle all the way to the back of the base

install the screw and motor mount. You may have to fiddle a bit to

get the lug on the ballnut into the hole in the saddle.

snug the motor mount screws to the base

slide the outer ball bearing into outside of the motor mount

install the spanner nut. Those look like ordinary ball bearings, so

they're not intended to take a whole bunch of side load.

That's a 32-pitch thread, so "just snug" should do. If it

loosens up under load you can always snug it tighter; if you

ding a bearing race it will have to be replaced.

CNCfusion's web site says to run the saddle all the way forward and

tighten the ballnut retaining screw. "All the way forward"

means "as far as you can go and still get the Allen wrench

between the saddle and the motor bracket." The purpose of

running the saddle forward is to try to align the bearings

and the ballnut. Run the saddle forward, loosen and re-snug

the motor bracket screws, then loosen the ballnut bracket

screw in the saddle and snug that. Now push the saddle all

the way forward and back. If it gets stiffer at one end,

you'll have to twiddle the ballnut bracket position until

the saddle moves freely throughout its travel.

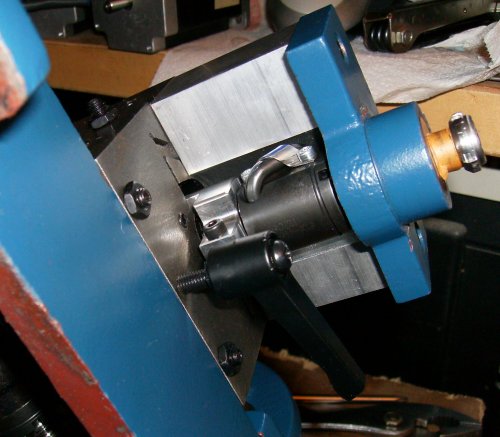

assemble the Lovejoy bits onto the ballnut and slide the motor shaft

through the bracket into the Lovejoy coupler. Snug set

screws, making sure the motor side screw is on the flat in the

shaft.

there was .060 or so negative axial clearance in my Lovejoy couplers.

That is, the motors would fail to touch the brackets by that

amount, and tightening the mounting screws put a lot of load

across the stiff plastic coupler crosses. I didn't like the

idea of that much end load on the motors. I emailed

CNCfusion and they said it wouldn't hurt anything. I still

didn't like that much preload, so I used a 1/4" Forstner bit

to put some simples in the crosses. Everything slid together

nicely then

there was .060 or so negative axial clearance in my Lovejoy couplers.

That is, the motors would fail to touch the brackets by that

amount, and tightening the mounting screws put a lot of load

across the stiff plastic coupler crosses. I didn't like the

idea of that much end load on the motors. I emailed

CNCfusion and they said it wouldn't hurt anything. I still

didn't like that much preload, so I used a 1/4" Forstner bit

to put some simples in the crosses. Everything slid together

nicely then

a ball-end metric Allen wrench would be a big help when installing

the motors, or soldering or brazing the provided wrench to a

piece of tubing so you can turn the wrench 360 degrees instead

of 90 degrees at a time. I found a long ball-end wrench set

at the local hardware store for $10. It was worth at least

that much not to have so much hassle with the screws. You

will probably run those screws in and out *many* times while

fitting the parts to the mill.

it's easier to see what you're doing if you turn the mill base

upside down

when wrestling the mill around the bench, try not to grab the Y-axis

motor mount no matter how convenient it looks as a handle

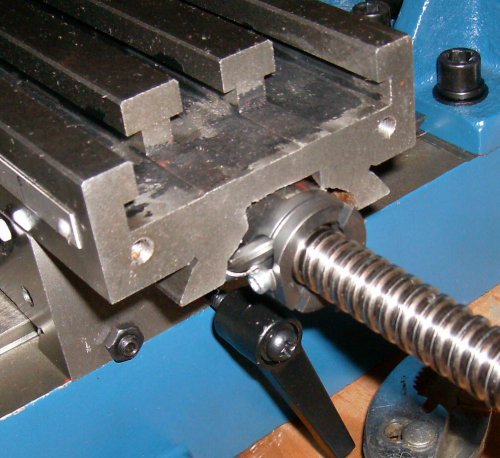

8. X-axis leadscrew

drop the X-axis leadscrew into the saddle. The threaded end goes to

the right.

drop the X-axis leadscrew into the saddle. The threaded end goes to

the right.

set the gib in the front of the dovetail. Make sure the dimples line

up with the gib screws

slide the table on from the left to right

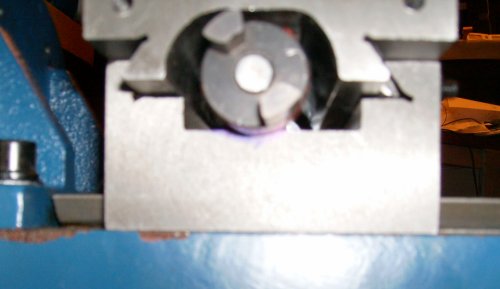

see if the ballnut contacts the underside of the table at any point.

if so, the table will have to be clearanced. Mine would

grate over rough bits and then jam about 2/3 of the way

across, even without the screw being mounted in its end blocks.

see if the ballnut contacts the underside of the table at any point.

if so, the table will have to be clearanced. Mine would

grate over rough bits and then jam about 2/3 of the way

across, even without the screw being mounted in its end blocks.

the back and top of the ballnut contacted the table, but the most

interference was the ball return tube on the front of the nut.

I removed +1/8" of the casting to get room for the nut.

the back and top of the ballnut contacted the table, but the most

interference was the ball return tube on the front of the nut.

I removed +1/8" of the casting to get room for the nut.

It took half a dozen tries to get things to move freely. I was concerned

about warping the table if I removed too much metal. Black spray paint

was a convenient way to see where the nut was hitting. Since the ballnut

is offset, the entire width of the table doesn't need to be ground to

clear it.

I had to take some off the middle to clear the ballscrew as well.

the C-shaped bit with X-/X+ goes on the right side, spacing the

original thrust washer and bracket out

the rectangular motor mount block goes on the left

screw the Lovejoy coupler to the X motor, assemble the cross and

inner joint, and feed them through the hole in the motor

mount. The motor-side coupler must be tightened before

mounting the motor unless you drill a hole in the mounting

bracket to allow access.

screw the Lovejoy coupler to the X motor, assemble the cross and

inner joint, and feed them through the hole in the motor

mount. The motor-side coupler must be tightened before

mounting the motor unless you drill a hole in the mounting

bracket to allow access.

tighten screws, making sure motor shaft flat is under the screw.

The ballscrew doesn't have a flat. I recommend filing or

milling a flat - that part of my screw was fairly soft, and

the setscrew raised a large burr where it contacted the

shaft. This made removing the coupler very difficult; I

had to pad everything, put it in the big vise, and beat it

out with a brass drift since I didn't have a puller small

enough to do the job. I probably tightened the set screw

too much, but a flat would still keep you from marring the

shaft.

if you try to tighten the motor with negative clearance in the Lovejoy

coupler, it can jam the ballscrew part of the coupler onto

the screw too tightly to be removed easily. Remember, you

can't just beat it off without damaging the ballnut.

there is very little clearance between the thrust bearing spacer

(the spacer on the right side of the table) and the ballnut.

On my particular machine, lifting the spacer up with my finger

while tightening the through-bolts was enough to get by

there is very little clearance between the thrust bearing spacer

(the spacer on the right side of the table) and the ballnut.

On my particular machine, lifting the spacer up with my finger

while tightening the through-bolts was enough to get by

unfortunately, on the left side of the table the Lovejoy coupler kit

the saddle casting before the table moved all the way to the

right. The saddle has to be relieved to accomodate the

length of the coupler. I ran the table to the right until

the coupler touched the saddle, ran a felt tip pen around

the coupler where it touched the table, and disassembled the

mill yet again.

unfortunately, on the left side of the table the Lovejoy coupler kit

the saddle casting before the table moved all the way to the

right. The saddle has to be relieved to accomodate the

length of the coupler. I ran the table to the right until

the coupler touched the saddle, ran a felt tip pen around

the coupler where it touched the table, and disassembled the

mill yet again.

Here we go! The table runs all the way to X+ now.

Here we go! The table runs all the way to X+ now.

I used a carbide burr and abrasive rolls in a 1/4" die grinder and

took +1/4" out.

I used a carbide burr and abrasive rolls in a 1/4" die grinder and

took +1/4" out.

Later, I saw some pictures of another

CNCFusion conversion on the web, and it had a smaller diameter

yoke on the X screw - the same one that was on my Y screw.

If I had looked closely, I could have swapped the yokes and

everything would have cleared. However, I now have room for

helical flex couplers if I want to upgrade.

Later, I saw some pictures of another

CNCFusion conversion on the web, and it had a smaller diameter

yoke on the X screw - the same one that was on my Y screw.

If I had looked closely, I could have swapped the yokes and

everything would have cleared. However, I now have room for

helical flex couplers if I want to upgrade.

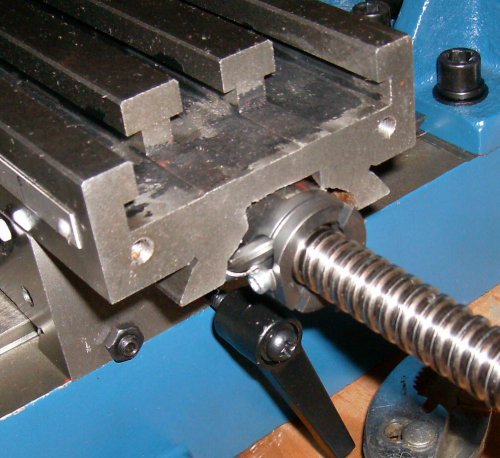

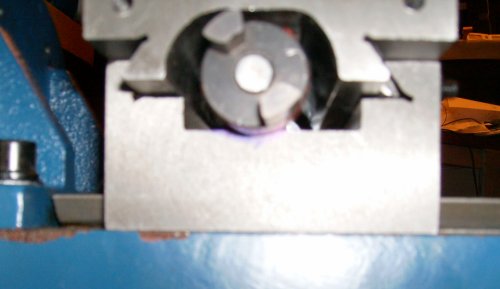

Finished installation from underneath.

Finished installation from underneath.

The X travel still seemed a bit rough in places. When I disassembled the

machine to do the limit switches, I noticed some screw marks in the Y ballnut

bracket. It was rubbing the X ballscrew.

The X travel still seemed a bit rough in places. When I disassembled the

machine to do the limit switches, I noticed some screw marks in the Y ballnut

bracket. It was rubbing the X ballscrew.

Some tape, some plastic bags, and a trip to the disc sander, and that problem

is fixed easily enough...

Some tape, some plastic bags, and a trip to the disc sander, and that problem

is fixed easily enough...

The CNCFusion Z-axis parts bolted right on without a hitch.

Unfortunately, the ballnut and screw blocked access to the gib screws

on the head casting. After looking at things for a while I decided

not to use the CNCFusion bits as delivered.

the left side of the ball nut has the recirculating tube for the

balls. On my mill, the ball nut scraped the rough side of

the clearance slot, so I had to grind some there, too.

the left side of the ball nut has the recirculating tube for the

balls. On my mill, the ball nut scraped the rough side of

the clearance slot, so I had to grind some there, too.

the left side of the ball nut has the recirculating tube for the

balls. On my mill, the ball nut scraped the rough side of

the clearance slot, so I had to grind some there, too.

the left side of the ball nut has the recirculating tube for the

balls. On my mill, the ball nut scraped the rough side of

the clearance slot, so I had to grind some there, too.

don't get too crazy clearancing the back of the base casting. More

then 1/8" or so clearance and the ballscrew may be able to

run off the last thread and drop balls out. If you want to

be precise, check your screw and nut and see exactly how far

the nut may go before you can lose your balls. Someday you

might need that extra .100" or so of Y travel

don't get too crazy clearancing the back of the base casting. More

then 1/8" or so clearance and the ballscrew may be able to

run off the last thread and drop balls out. If you want to

be precise, check your screw and nut and see exactly how far

the nut may go before you can lose your balls. Someday you

might need that extra .100" or so of Y travel

CNCfusion's forum says you should be able to hold the ballscrew firmly

in one hand and use pliers to run the nut down snugly against

the ball bearing. This wasn't even in the same universe as

the screw and nut I got. Using a piece of old leather belt

to pad the jaws, I tried holding the screw with 10" pliers

and still couldn't get enough of a grip to run the threads

past the locking ring in the nut. I was leery of using Vise

Grips, so I picked away at the plastic locking ring with a

penknife until I could run the nut on. I figured I could use

a drop of Loctite later if needed. You might try padding the

screw with leather or wood and holding it in a bench vise to

run the nut on and off a few times to loosen it up. My nut

has plier marks all over it now. Surely there's a spanner

wrench to fit the thing, somewhere...

CNCfusion's forum says you should be able to hold the ballscrew firmly

in one hand and use pliers to run the nut down snugly against

the ball bearing. This wasn't even in the same universe as

the screw and nut I got. Using a piece of old leather belt

to pad the jaws, I tried holding the screw with 10" pliers

and still couldn't get enough of a grip to run the threads

past the locking ring in the nut. I was leery of using Vise

Grips, so I picked away at the plastic locking ring with a

penknife until I could run the nut on. I figured I could use

a drop of Loctite later if needed. You might try padding the

screw with leather or wood and holding it in a bench vise to

run the nut on and off a few times to loosen it up. My nut

has plier marks all over it now. Surely there's a spanner

wrench to fit the thing, somewhere...

there was .060 or so negative axial clearance in my Lovejoy couplers.

That is, the motors would fail to touch the brackets by that

amount, and tightening the mounting screws put a lot of load

across the stiff plastic coupler crosses. I didn't like the

idea of that much end load on the motors. I emailed

CNCfusion and they said it wouldn't hurt anything. I still

didn't like that much preload, so I used a 1/4" Forstner bit

to put some simples in the crosses. Everything slid together

nicely then

there was .060 or so negative axial clearance in my Lovejoy couplers.

That is, the motors would fail to touch the brackets by that

amount, and tightening the mounting screws put a lot of load

across the stiff plastic coupler crosses. I didn't like the

idea of that much end load on the motors. I emailed

CNCfusion and they said it wouldn't hurt anything. I still

didn't like that much preload, so I used a 1/4" Forstner bit

to put some simples in the crosses. Everything slid together

nicely then drop the X-axis leadscrew into the saddle. The threaded end goes to

the right.

drop the X-axis leadscrew into the saddle. The threaded end goes to

the right. see if the ballnut contacts the underside of the table at any point.

if so, the table will have to be clearanced. Mine would

grate over rough bits and then jam about 2/3 of the way

across, even without the screw being mounted in its end blocks.

see if the ballnut contacts the underside of the table at any point.

if so, the table will have to be clearanced. Mine would

grate over rough bits and then jam about 2/3 of the way

across, even without the screw being mounted in its end blocks.

the back and top of the ballnut contacted the table, but the most

interference was the ball return tube on the front of the nut.

I removed +1/8" of the casting to get room for the nut.

the back and top of the ballnut contacted the table, but the most

interference was the ball return tube on the front of the nut.

I removed +1/8" of the casting to get room for the nut.

screw the Lovejoy coupler to the X motor, assemble the cross and

inner joint, and feed them through the hole in the motor

mount. The motor-side coupler must be tightened before

mounting the motor unless you drill a hole in the mounting

bracket to allow access.

screw the Lovejoy coupler to the X motor, assemble the cross and

inner joint, and feed them through the hole in the motor

mount. The motor-side coupler must be tightened before

mounting the motor unless you drill a hole in the mounting

bracket to allow access. there is very little clearance between the thrust bearing spacer

(the spacer on the right side of the table) and the ballnut.

On my particular machine, lifting the spacer up with my finger

while tightening the through-bolts was enough to get by

there is very little clearance between the thrust bearing spacer

(the spacer on the right side of the table) and the ballnut.

On my particular machine, lifting the spacer up with my finger

while tightening the through-bolts was enough to get by

unfortunately, on the left side of the table the Lovejoy coupler kit

the saddle casting before the table moved all the way to the

right. The saddle has to be relieved to accomodate the

length of the coupler. I ran the table to the right until

the coupler touched the saddle, ran a felt tip pen around

the coupler where it touched the table, and disassembled the

mill yet again.

unfortunately, on the left side of the table the Lovejoy coupler kit

the saddle casting before the table moved all the way to the

right. The saddle has to be relieved to accomodate the

length of the coupler. I ran the table to the right until

the coupler touched the saddle, ran a felt tip pen around

the coupler where it touched the table, and disassembled the

mill yet again. Here we go! The table runs all the way to X+ now.

Here we go! The table runs all the way to X+ now.

I used a carbide burr and abrasive rolls in a 1/4" die grinder and

took +1/4" out.

I used a carbide burr and abrasive rolls in a 1/4" die grinder and

took +1/4" out.

Later, I saw some pictures of another

CNCFusion conversion on the web, and it had a smaller diameter

yoke on the X screw - the same one that was on my Y screw.

If I had looked closely, I could have swapped the yokes and

everything would have cleared. However, I now have room for

helical flex couplers if I want to upgrade.

Later, I saw some pictures of another

CNCFusion conversion on the web, and it had a smaller diameter

yoke on the X screw - the same one that was on my Y screw.

If I had looked closely, I could have swapped the yokes and

everything would have cleared. However, I now have room for

helical flex couplers if I want to upgrade. Finished installation from underneath.

Finished installation from underneath. The X travel still seemed a bit rough in places. When I disassembled the

machine to do the limit switches, I noticed some screw marks in the Y ballnut

bracket. It was rubbing the X ballscrew.

The X travel still seemed a bit rough in places. When I disassembled the

machine to do the limit switches, I noticed some screw marks in the Y ballnut

bracket. It was rubbing the X ballscrew.

Some tape, some plastic bags, and a trip to the disc sander, and that problem

is fixed easily enough...

Some tape, some plastic bags, and a trip to the disc sander, and that problem

is fixed easily enough...